High Speed Ge/Silicon Avalanche Photodiode

An avalanche photoelectric and diode technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as impact, increased capacitance, and increased RC time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

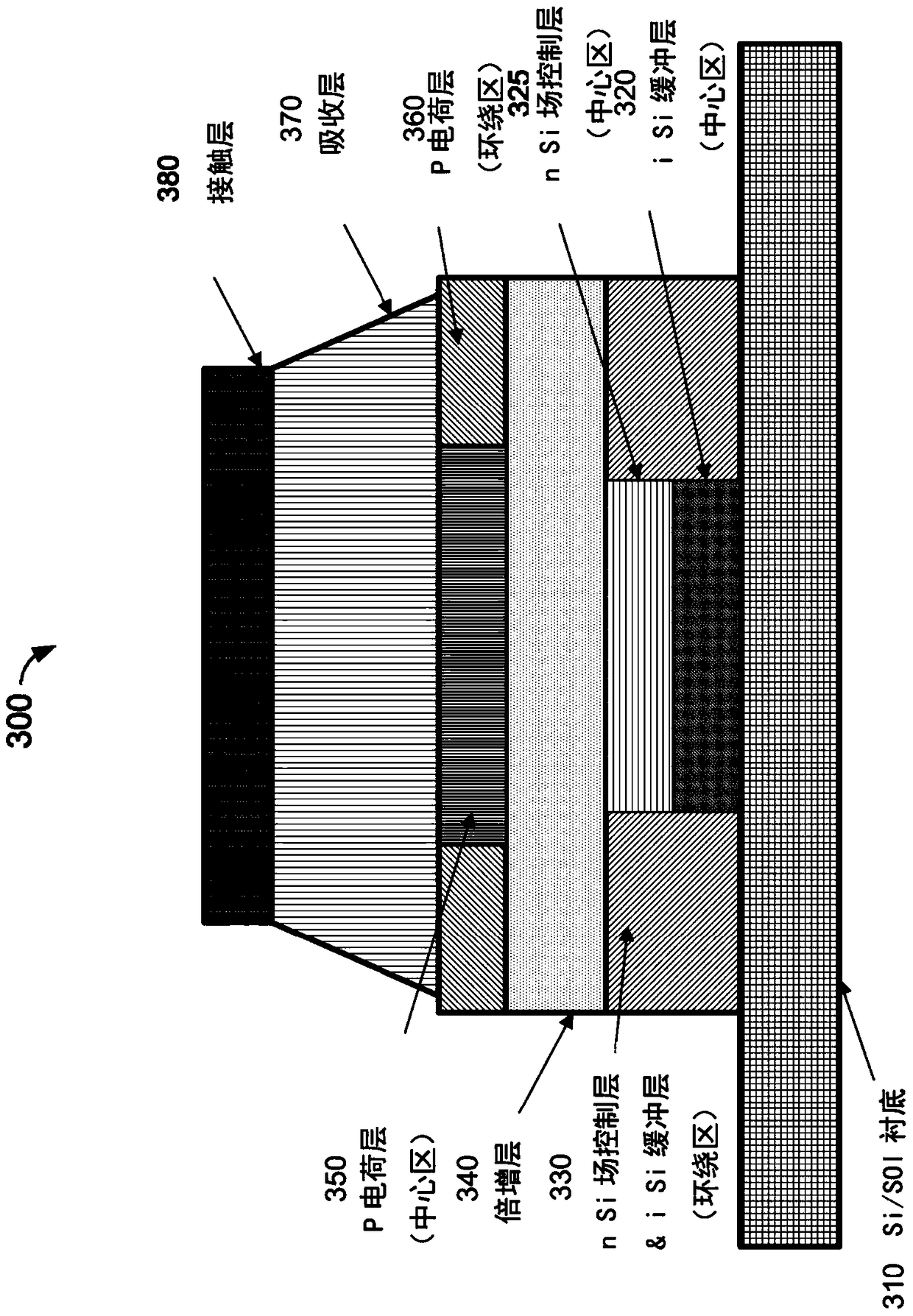

[0016] The present invention provides various embodiments of novel germanium / silicon avalanche photodiode (Ge / Si APD) structures that address the aforementioned problems associated with existing Ge / Si APD designs.

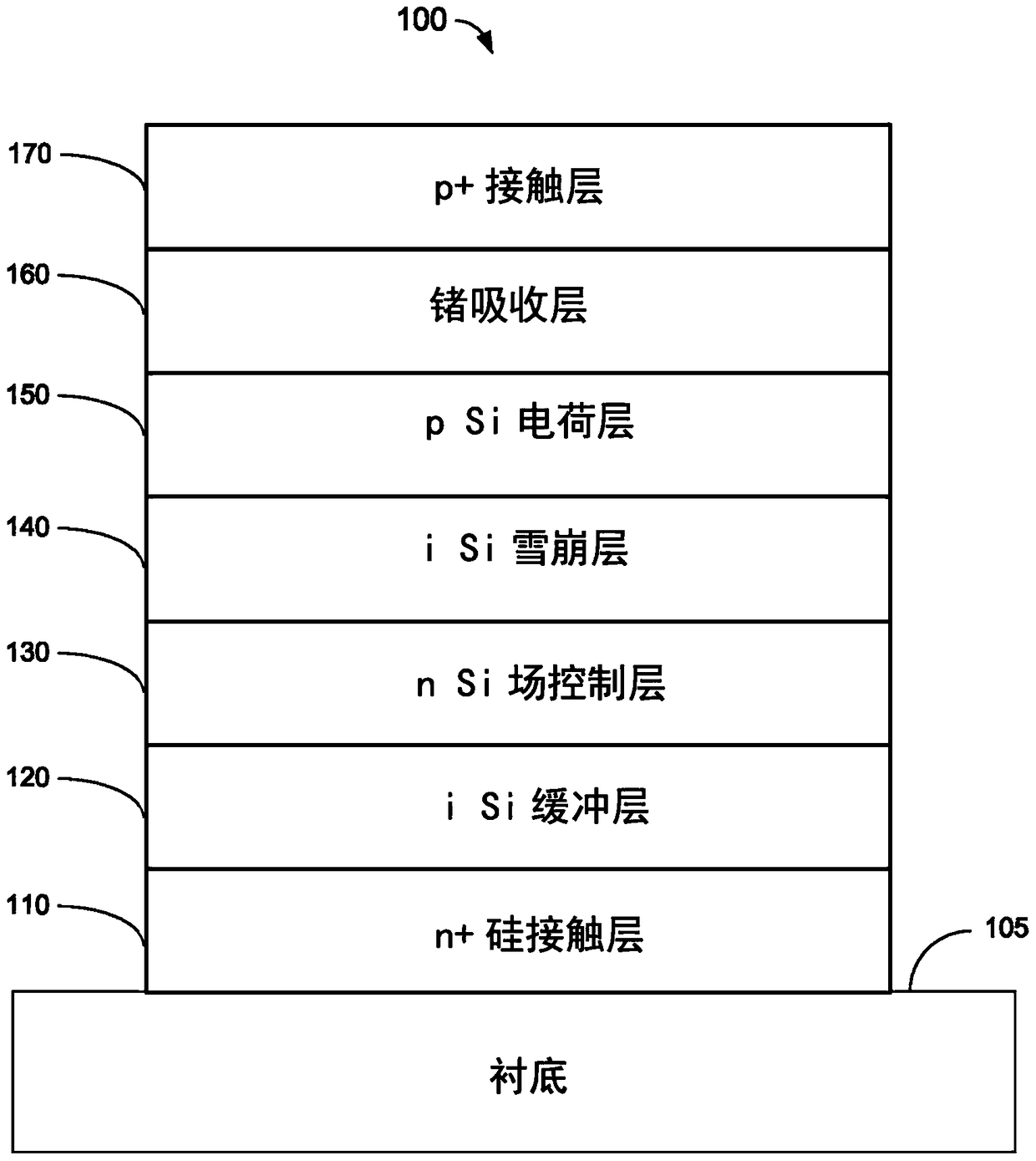

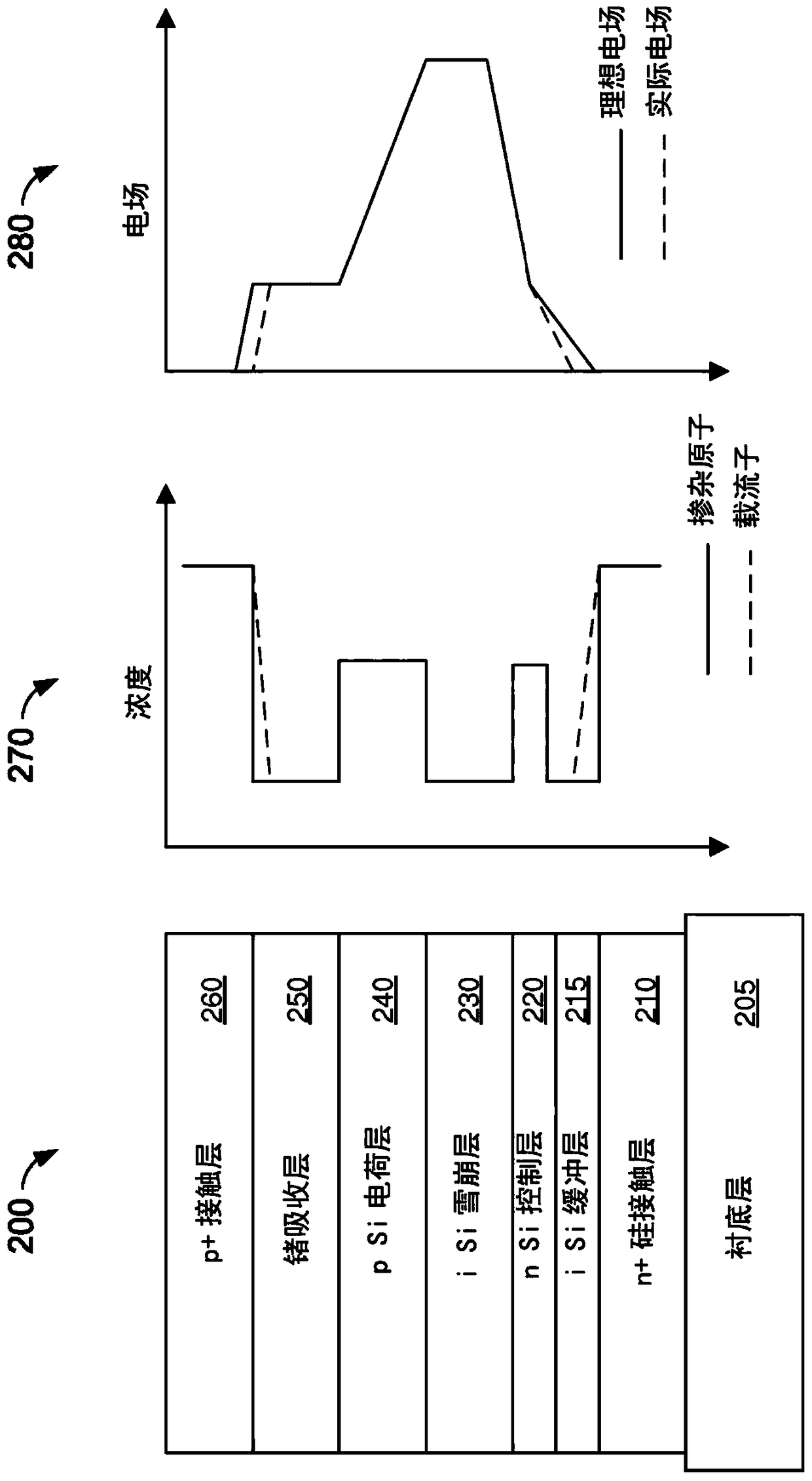

[0017] figure 1 A Ge / Si APD structure 100 is shown in accordance with one embodiment of the invention. refer to figure 1 , Ge / Si APD structure 100 may include substrate layer 105 , bottom contact layer 110 , buffer layer 120 , electric field control layer 130 , avalanche layer 140 , charge layer 150 , absorber layer 160 and top contact layer 170 . The substrate layer 105 may be prepared from a bulk silicon wafer or a silicon-on-insulator (SOI) wafer. The bottom contact layer 110 may be a heavily n-doped (n+) silicon contact layer. The buffer layer 120 may be an intrinsic silicon (i-Si) buffer layer. The electric field control layer 130 can be an n-doped silicon electric field control layer for controlling the electric field distribution in the avalanche layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com