Sheet Metal Cutting Equipment

A technology for cutting equipment and metal plates, applied in metal sawing equipment, metal processing equipment, sawing machine devices, etc., can solve the problems of difficult to completely remove burrs, time and cost consumption, etc., to save cost and time, improve cutting quality, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

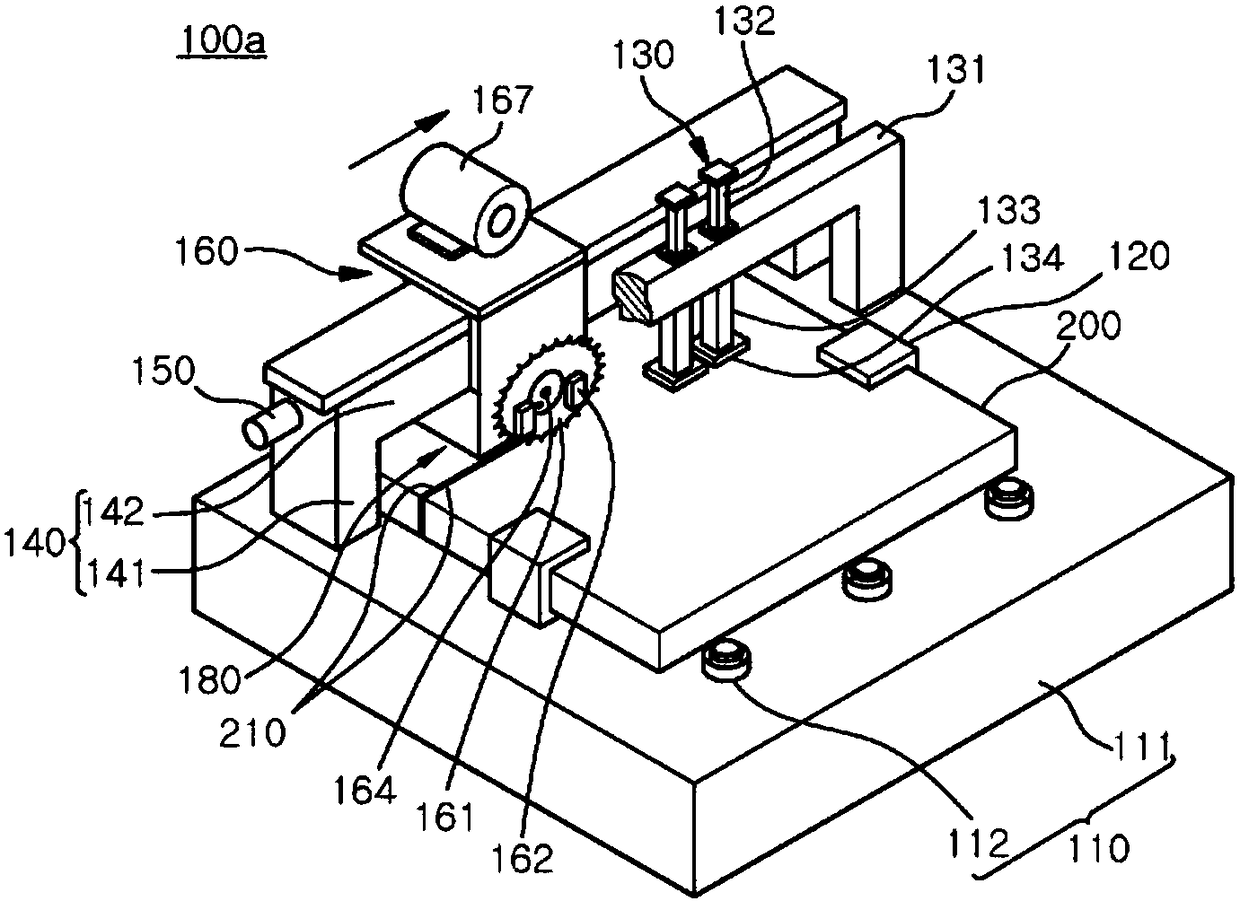

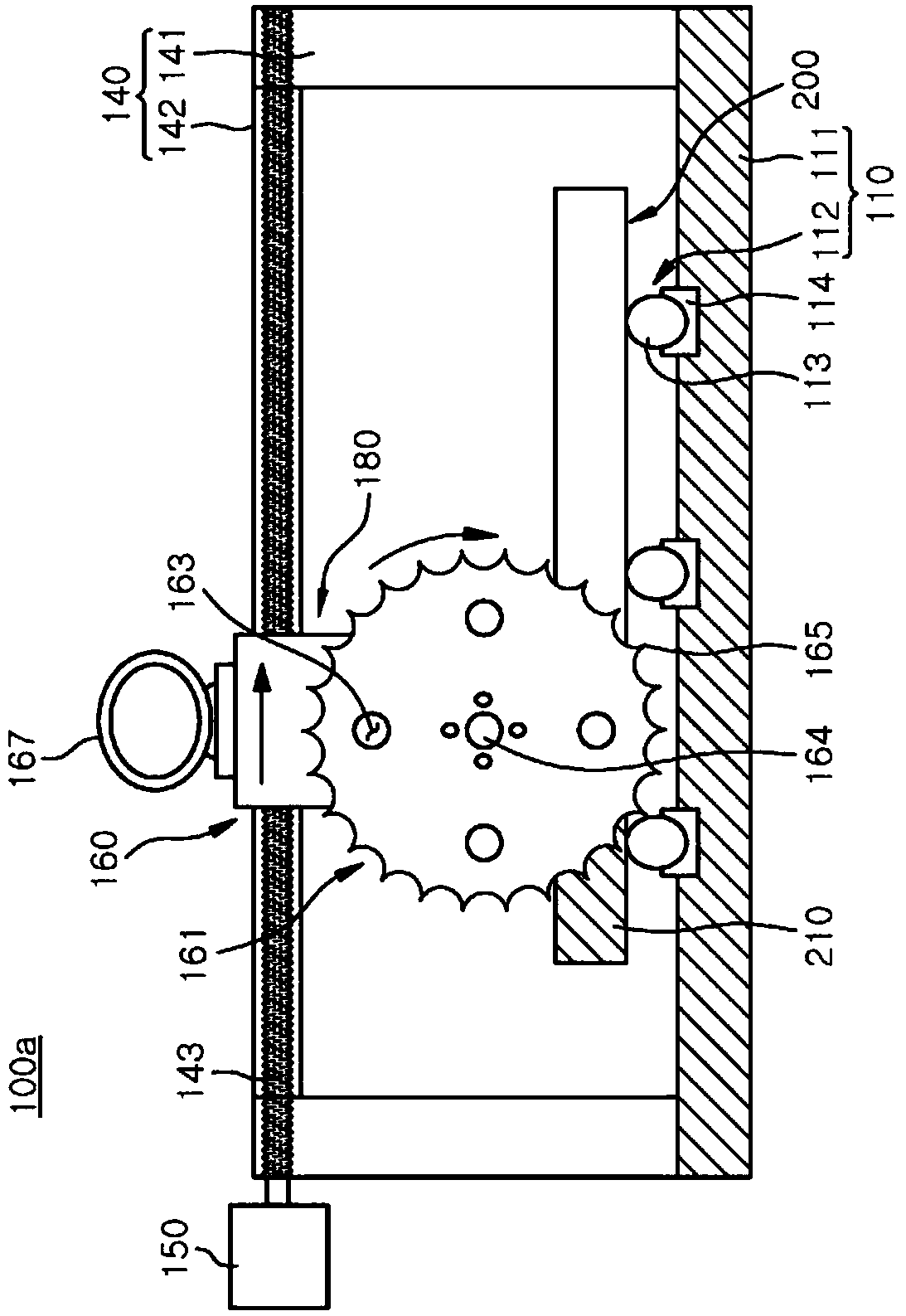

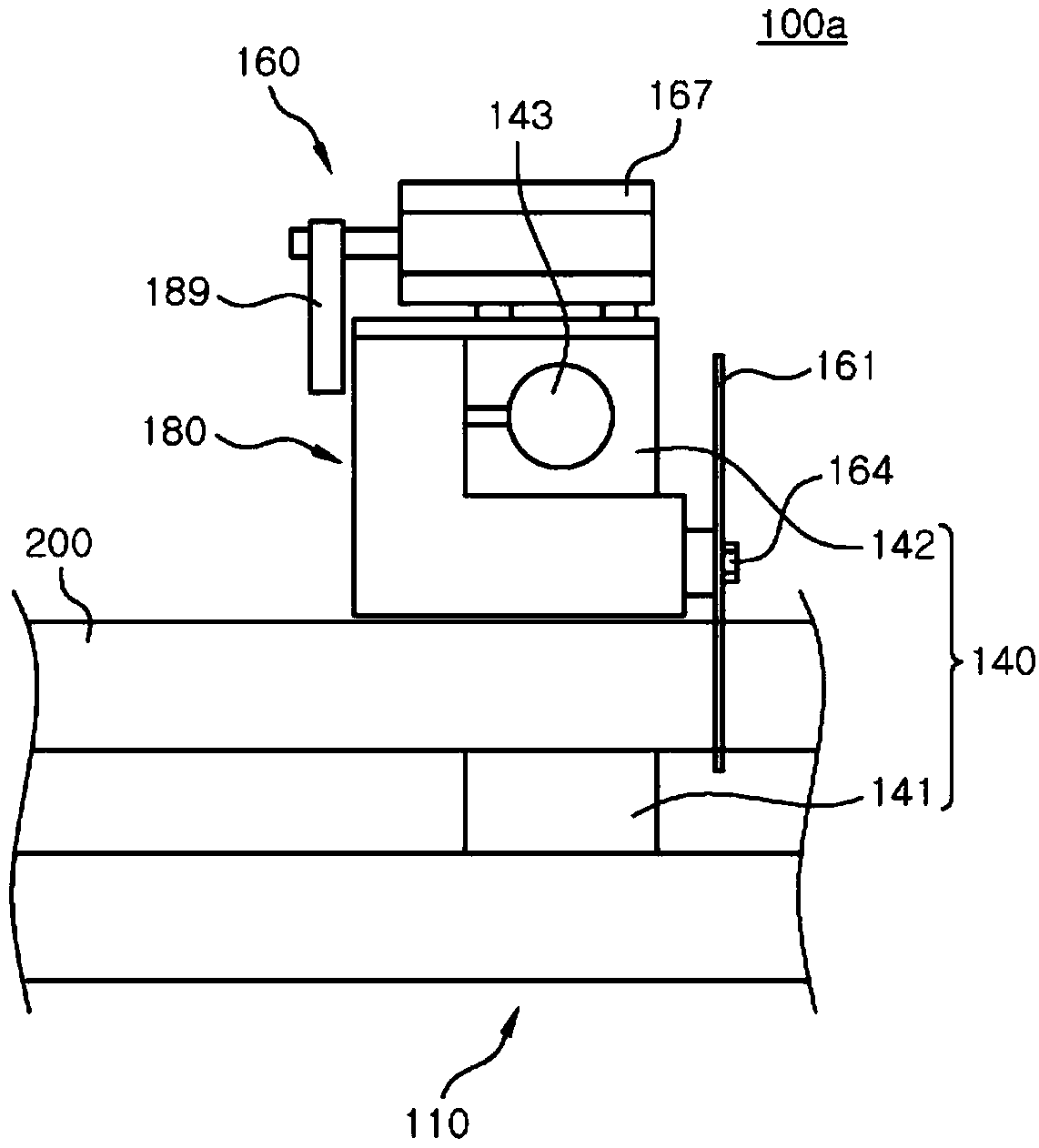

[0067] figure 1 is a perspective view illustrating a sheet metal cutting apparatus 100a of an exemplary embodiment of the present disclosure, and figure 2 is schematically shown figure 1 A frontal cross-sectional view of the sheet metal cutting apparatus 100a shown in . image 3 is schematically shown figure 1 A side cross-sectional view of the sheet metal cutting apparatus 100a shown in . In the following, reference will be made to Figure 1 to Figure 3 A sheet metal cutting apparatus 100a of an exemplary embodiment is described.

[0068] Such as Figure 1 to Figure 3 As shown in , the metal plate cutting apparatus 100 a of the exemplary embodiment may include a table 110 , a frame unit 140 and a cutting unit 160 . The cutting unit 160 may include: a first driving unit 167; a saw unit 161 having a rotation shaft 164 disposed above the metal plate 200 placed on the upper surface of the table 110; and a power transmission unit 180, It is configured to transmit drive pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com