Embossing roller

An embossing roller and negative pressure technology, applied in coatings, embossed decorative parts, household appliances, etc., can solve problems such as complex machine openings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

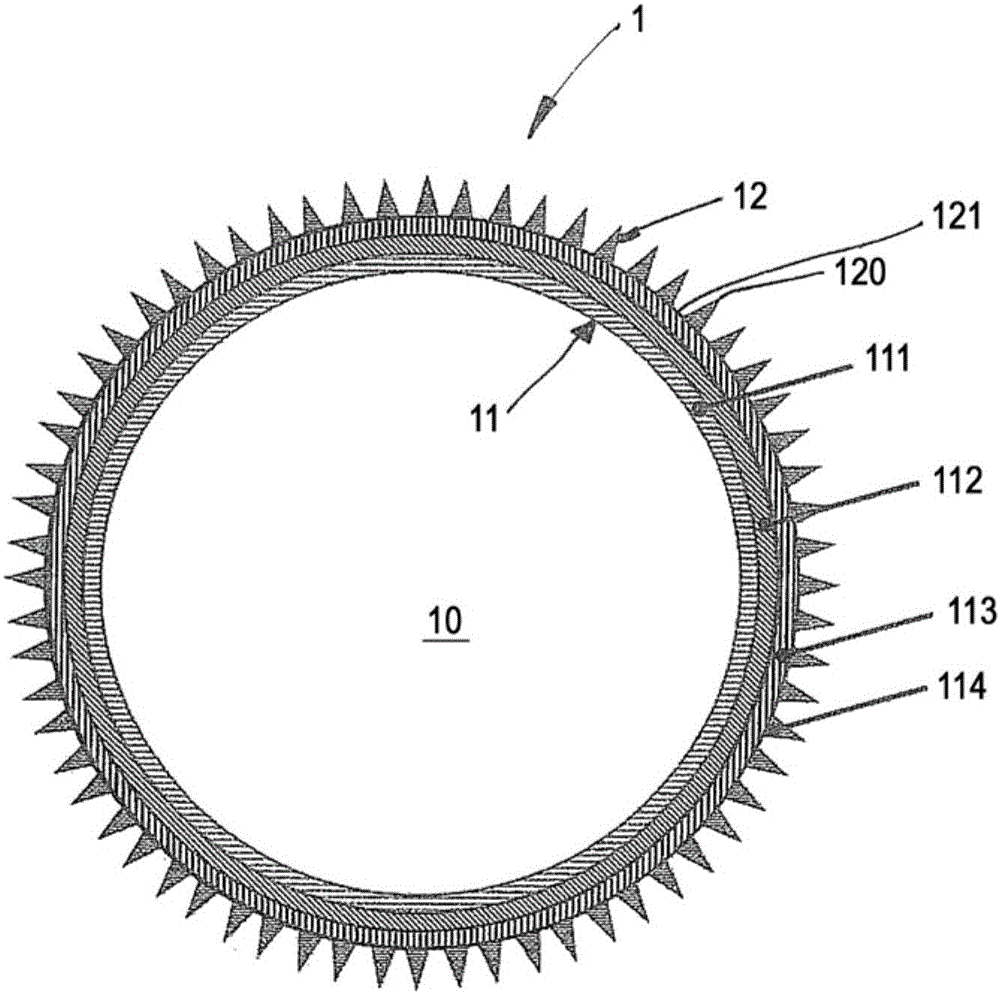

[0037] The single FIGURE shows a cross-section through an embossing roller 1 with an inner hollow space 10 , in which the hollow space is not shown in detail, but a negative pressure can be applied in a known manner. The embossing roll 1 is closed at the ends except for the line to a source of negative pressure (not shown). The hollow space 10 is surrounded by a cylindrically designed wall 11 in the illustrated embodiment, which comprises in total four discrete layers 111 successively succeeding one another by the hollow space 10 in the direction of the cylindrical outer surface 12 of the embossing roller 1 . , 112, 113, 114. All individual layers 111 , 112 , 113 , 114 are formed based on an epoxy resin mixture filled with a filler material and are each connected adjacent to each other.

[0038] The layers 111 , 112 , 113 , 114 can have the same or different layer thicknesses.

[0039] The outermost layer 11 adjacent to the outer surface has a structured outer surface 12 com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com