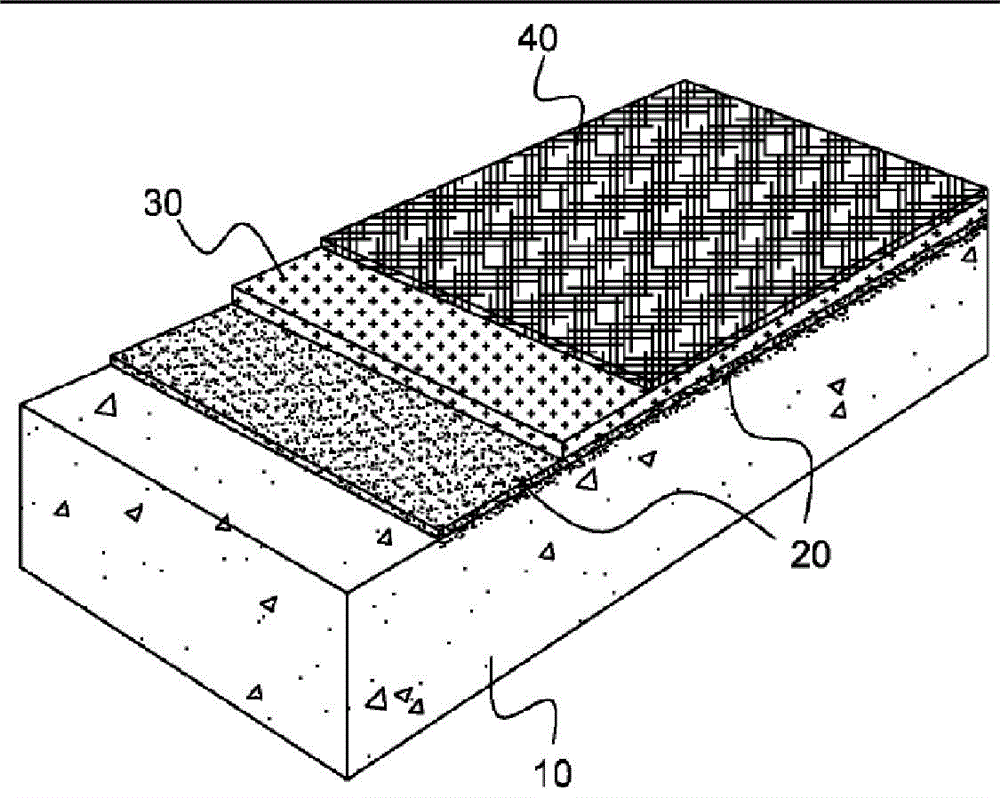

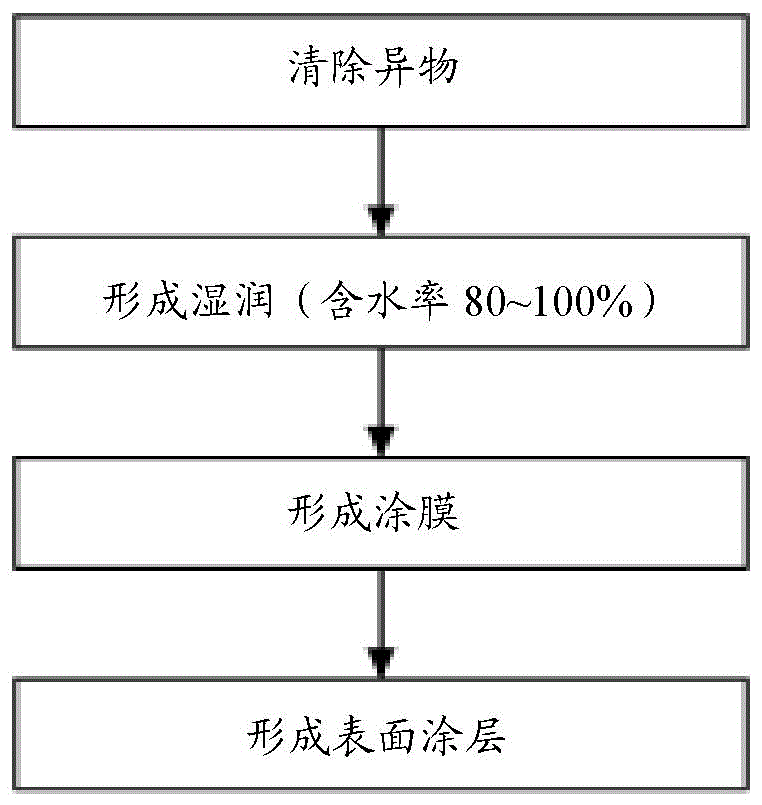

Inorganic anti-neutralization, waterproof, and anti-corrosion floor finish material coating composition that can be applied without a primer in the wet state of concrete moisture content of 100%, and construction of anti-neutralization, waterproof, anti-corrosion, and floor materials using it method

A wet state, finishing material technology, applied in the direction of sustainable waste treatment, floor, building construction, etc., can solve the problems of low moisture resistance, no permeability, and inability to use stored water, etc., to achieve anti-wheel Friction and abrasion resistance, excellent waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] Mix 250 parts by weight of inorganic powder with 100 parts by weight of acrylic acid aqueous solution (solid content 20wt%, MMA series acrylic acid copolymer) to form an inorganic coating composition, and then apply the inorganic coating composition on the surface of a concrete structure (moisture content 100 %) with a size of 5×5m and a thickness of 1mm or more, and then check the formation of the coating film and cracking after 24 hours and show the results in [Table 1].

[0104] At this time, the inorganic powder consists of 100 parts by weight of cementitious material powder (white cement: blast furnace slag particles 1:1 by weight), 60 parts by weight of silicon powder (400 mesh), 15 parts by weight of inorganic pigment (zinc oxide), 2 parts by weight of alumina cement, 0.5 parts by weight of PC (Polycarboxylate) dispersant, 0.3 parts by weight of powder defoamer (trade name: defoma), 0.2 parts by weight of surface stabilizer (trade name: ONICELL), 0.1 part by weigh...

Embodiment 2

[0106] 250 parts by weight of inorganic powder and 80 parts by weight of silica (No. 7) are mixed with 100 parts by weight of acrylic acid aqueous solution (solid content 20wt%, MMA-based acrylic copolymer) to form an inorganic coating composition,

[0107] Apply the inorganic coating composition on the surface of the concrete structure (moisture content 100%) with a size of 5 x 5 m and a thickness of 1 to 3 mm, and then check whether the coating film is formed and cracked after 24 hours [Table 1 ] to display the result.

[0108] At this time, the inorganic powder consists of 100 parts by weight of cementitious material powder (white cement: blast furnace slag particles 1:1 ratio), 60 parts by weight of silicon powder (400 mesh), 15 parts by weight of inorganic pigment (zinc oxide), 2 parts by weight Bauxite cement, 0.5 parts by weight of PC (Polycarboxylate) dispersant, 0.3 parts by weight of powder defoamer (trade name: defoma), 0.2 parts by weight of surface stabilizer (tra...

Embodiment 3

[0110] 250 parts by weight of inorganic powder and 120 parts by weight of silica (No. 6) are mixed with 100 parts by weight of acrylic acid aqueous solution (solid content 20wt%, MMA-based acrylic copolymer) to form an inorganic coating composition,

[0111] Apply the inorganic coating composition on the surface of the concrete structure (moisture content 100%) with a size of 5 x 5 m and a thickness of 3 to 5 mm, and then check whether the coating film is formed and cracked after 24 hours [Table 1 ] to display the result.

[0112]At this time, the inorganic powder consists of 100 parts by weight of cementitious material powder (white cement: blast furnace slag particles 1:1 ratio), 60 parts by weight of silicon powder (400 mesh), 15 parts by weight of inorganic pigment (zinc oxide), 2 parts by weight Bauxite cement, 0.5 parts by weight of PC (Polycarboxylate) dispersant, 0.3 parts by weight of powder defoamer (trade name: defoma), 0.2 parts by weight of surface stabilizer (tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com