Efficient green almond skin removing machine

A kind of green skin machine and efficient technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of long time consumption, low operation efficiency, and affecting sales price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

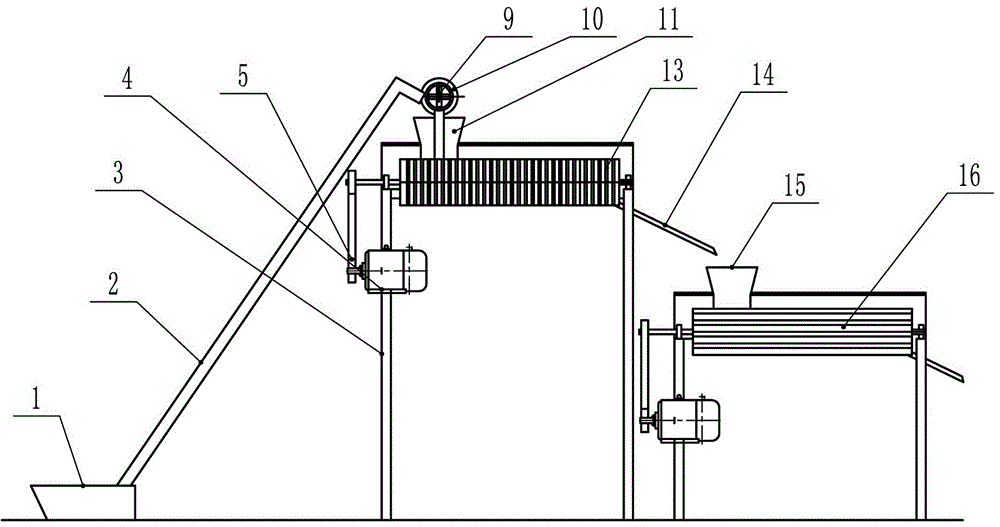

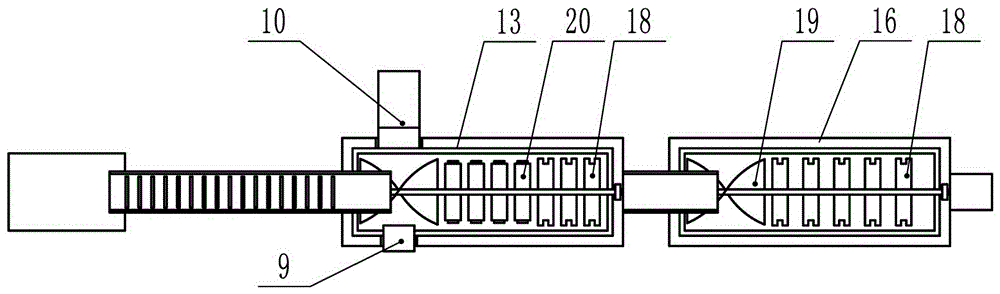

[0010] A high-efficiency almond peeling machine, such as figure 1 , figure 2 , image 3 As shown, it includes the hopper 1, the lifting conveyor belt 2 and the motor 4 installed on the frame 3, the frame 3 is divided into two front and rear high and low arrangements, and the upper part of the high frame is horizontally equipped with a drum separation screen with a feed inlet 11 13. The drum separator 13 is provided with a central shaft driven by the motor 4 through the chain 5 to rotate. A grid separation screen 16 with a feed hopper 15 is horizontally arranged on the top of the low frame. The central shaft in the bar separation screen 16 is also driven by a corresponding motor to rotate.

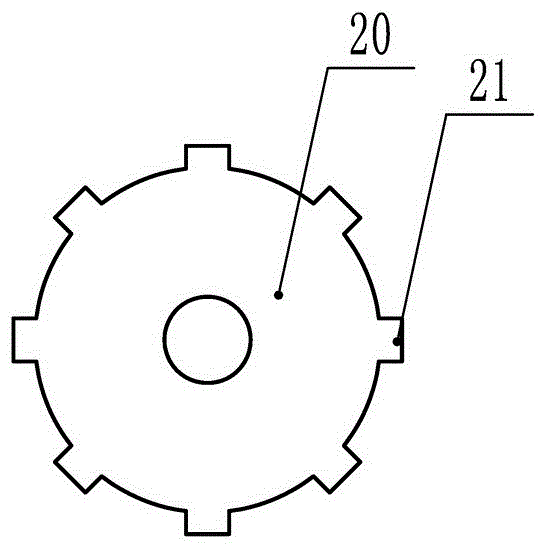

[0011] On the central axis in the drum separating screen 13, the spiral auger 19, the rubbing roller 20 and the crown-shaped blade 18 are successively arranged from the front to the back. greater than the outer diameter of the almond core, the axial outer peripheral surface of each kne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com