Method for preparing complete denture closed impression from novel edge trimming and shaping material

A complete denture and closed-mouth technology, which is applied in the field of complete denture production, can solve the problems affecting the use effect of complete dentures, poor edge shaping effect, attention and explanation of edge shaping materials, etc., to simplify clinical operation content and program, improve closure effect, improve the effect of edge closure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for making a closed mouth impression of a complete denture, the steps are as follows:

[0032] ⑴Take the initial impression, perfuse the initial impression to make the initial model: use the alginate impression material to obtain the initial impression of the upper and lower edentulous jaws of the patient, pour the initial impression with ordinary plaster, and after the plaster hardens, reproduce the initial model

[0033] ⑵ Make a temporary base and individual trays on the initial model: Use base wax to buffer the upper and lower jaw undercuts and hard areas, and use temporary base materials to make temporary bases and individual trays. The temporary base material is a photocurable base resin material

[0034] ⑶ Make a wax embankment on the temporary base and individual trays, and conduct a test occlusion in the patient's mouth to determine the relationship between the upper and lower jaws;

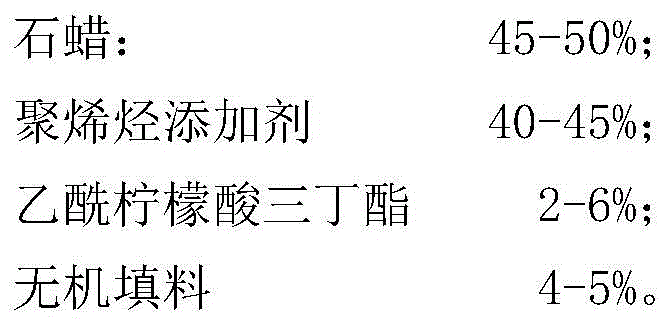

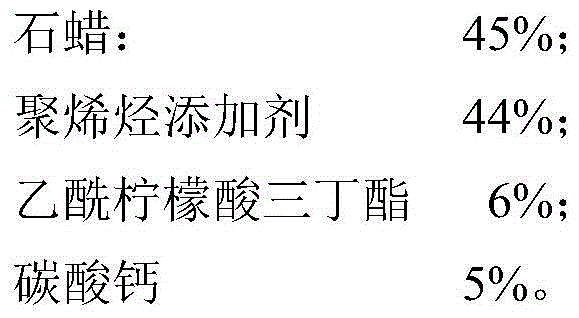

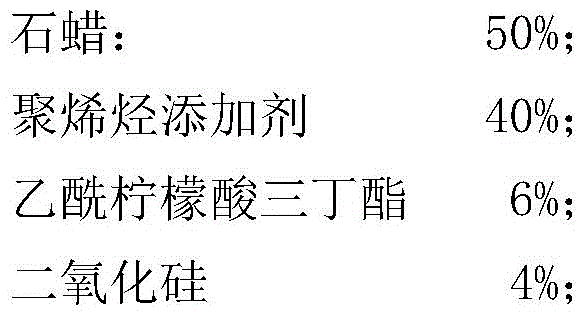

[0035] ⑷Paste the edge plastic material on the edge of the temporar...

Embodiment 2

[0043] A method for making a closed mouth impression of a complete denture, the steps are as follows:

[0044] The finished edentulous tray was used to take the alginate impression material, and the upper and lower edentulous initial impressions were taken by the traditional open-mouth impression method, and the ordinary plaster model was reproduced. Use room temperature curing denture base resin to make a temporary base, try on the temporary base in the oral cavity, and trim the edge height of the base, generally 1 mm to 2 mm from the gingiva-labial and buccal sulcus. Cheek and lingual frenulum. Make a wax embankment on the temporary base, and accurately record the vertical distance and cusp staggered position; paste the edge plastic material on the edge of the temporary base, introduce it into the patient's mouth, and guide the patient to perform edge shaping to complete the edge shaping After the molding work, take out the temporary base with the wax embankment and the edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com