Wheat dampening control equipment

A technology of control equipment and water quantity control, applied in the application, grain processing, grain milling and other directions, can solve the problem that the accuracy of wheat water impingement control equipment is not further improved or decreased, so as to improve the detection accuracy and processing efficiency, and promote the development process. , the effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, wheat impingement control equipment.

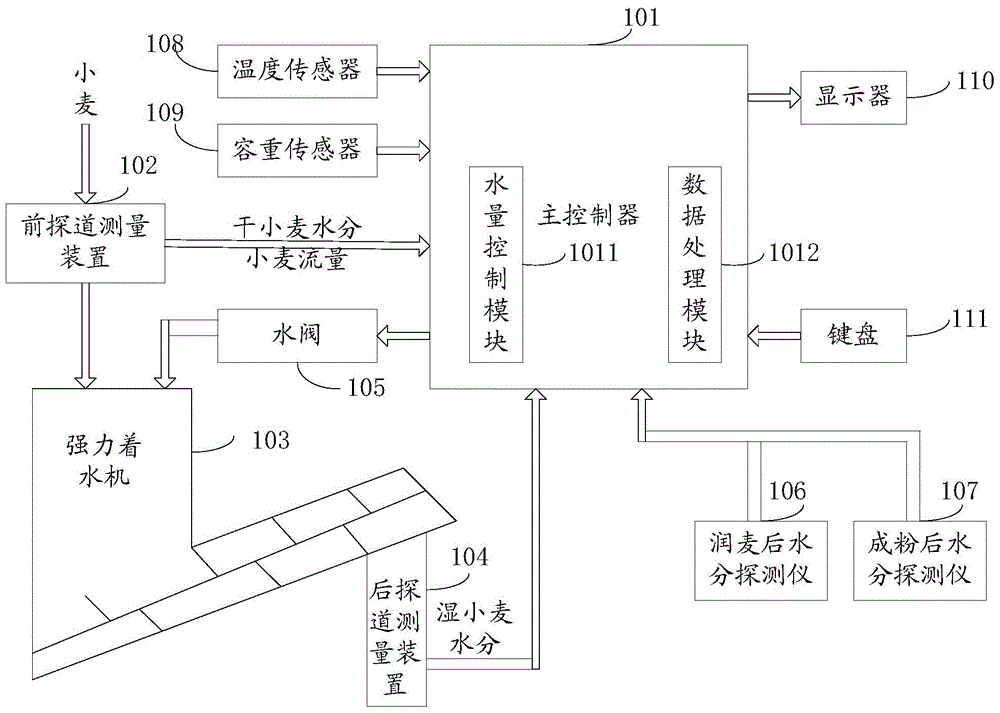

[0031] figure 1 It is a structural schematic diagram of the wheat impingement control equipment of Embodiment 1 of the present invention, as figure 1 As shown, the embodiment of the present invention includes a powerful flooding machine 103, a water valve 105 and a main controller 101, and also includes a front probe measurement device 102 and a rear probe measurement device 104, wherein:

[0032] The front probe measuring device 102 is suitable for measuring dry wheat moisture content and wheat flow;

[0033] The back probe measuring device 104 is suitable for measuring the moisture content of wet wheat after watering;

[0034] The main controller 101 calculates the corresponding water flow rate according to the measured moisture content of the dry wheat, the wheat flow rate and the set moisture value, and sends a rough adjustment command to the water valve 105, and sends a rough adjustment command to the strong wa...

Embodiment 2

[0048]Embodiment 2, wheat impingement control equipment.

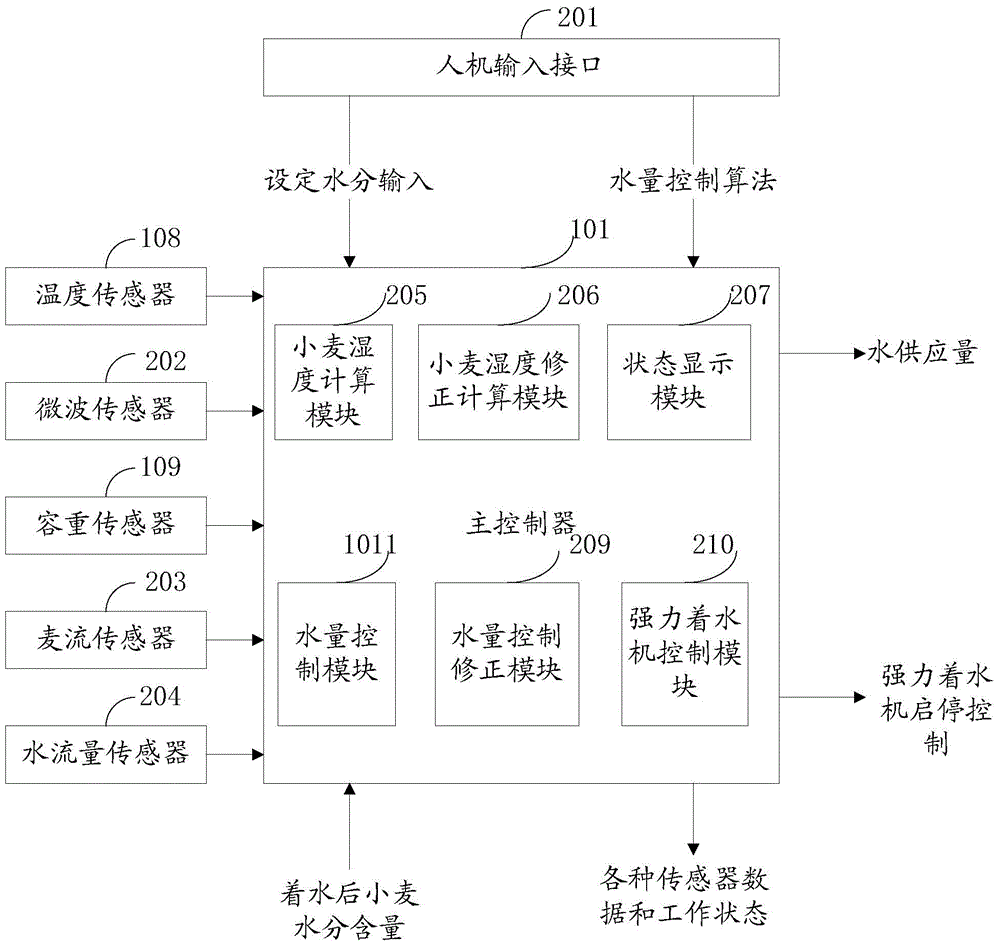

[0049] figure 2 It is a functional block diagram of the wheat impingement control device according to the second embodiment of the present invention. Such as figure 2 As shown, the embodiment of the present invention includes a man-machine input interface 201, a microwave sensor 202, a wheat flow sensor 203, a water flow sensor 204, a main controller 101, a temperature sensor 108, a bulk density sensor 109, figure 1 Said water quantity control module 1011 also comprises water quantity control correction module 209, and said data processing module 1012 is divided into wheat humidity calculation module 205, wheat humidity correction calculation module 206 again, wherein:

[0050] The water quantity control correction module 209 corrects the opening degree of the water valve through a filtering algorithm through the difference between the moisture content of the wet wheat after watering and the set moisture value obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com