Battery sealing agent spraying device

A spraying device and sealing agent technology, which is applied to the surface coating liquid device, coating, etc., can solve the problem that the sealing agent cannot be completely coated on the surface of the battery steel case, the overall structure of the equipment is complicated, and the synchronization control is difficult and other problems, to achieve the effect of improving utilization rate, improving spraying quality and continuous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

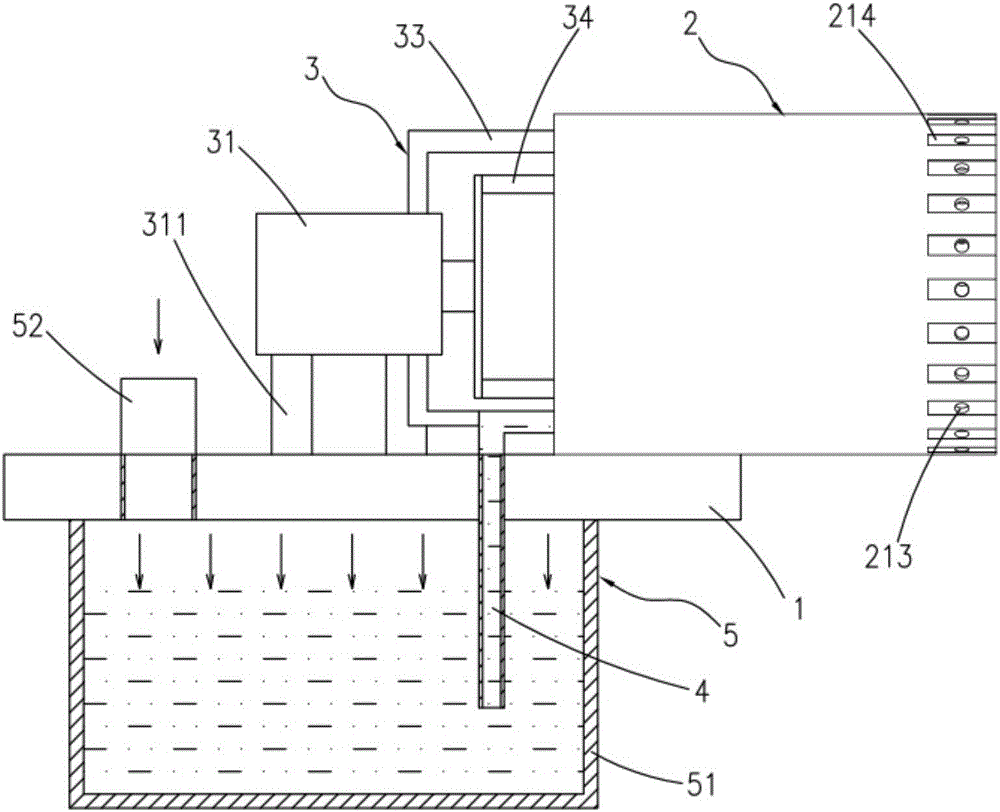

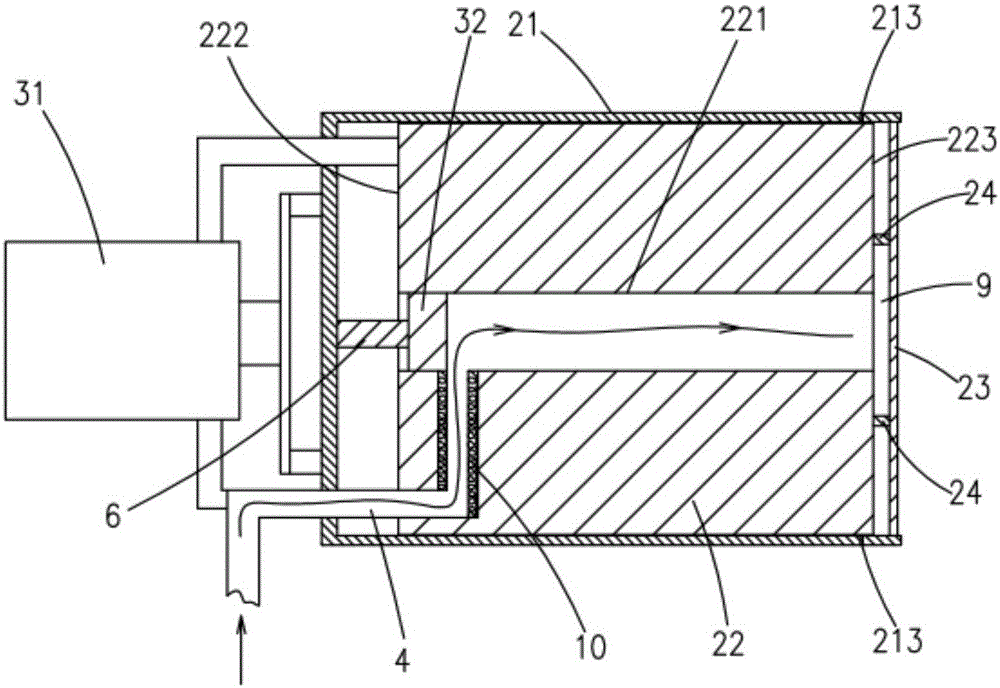

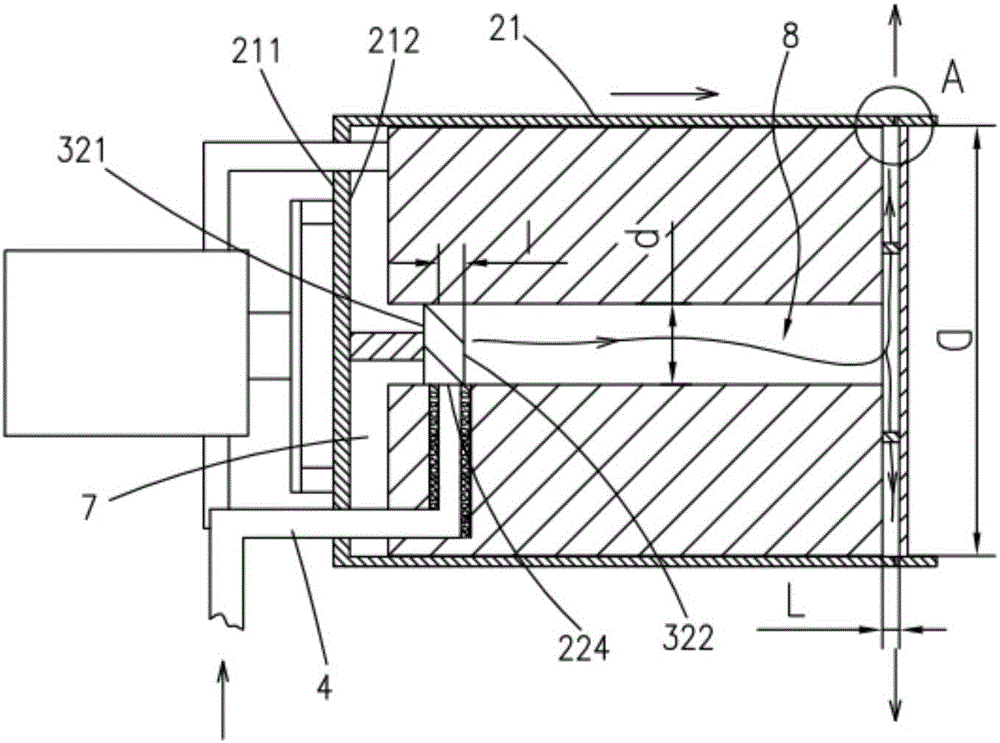

[0037] Such as figure 1 As shown, the present invention provides a battery sealing agent spraying device, including a fixed seat 1, a spray head 2, a pushing mechanism 3, an agent tube 4 and a sealing agent delivery mechanism 5, the spray head 2 is installed on the fixed seat 1, and the sealing The agent delivery mechanism 5 is arranged under the fixed seat 1, and communicates with the nozzle 2 through the agent tube 4; as figure 2 with image 3As shown, the spray head 2 includes a spray cover 21 whose outer diameter is compatible with the inner diameter of the battery steel case to be coated and an agent tank 22 placed in the cavity of the spray cover 21. The inside of the agent tank 22 is opened along its axial direction for use The through hole 221 for containing the sealing agent; the pushing mechanism 3 includes a cylinder 31 and a piston 32 arranged in the through hole 221 for sealing and sliding, and the cylinder 31 and the piston 32 are relatively arranged on the out...

Embodiment 2

[0050] Such as Figure 8 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. This embodiment two and figure 2 The difference of the first embodiment shown is that: the air chamber 7 is symmetrically provided with a spring 11, one end of the spring 11 is fixedly connected to the inner wall 212 of the spray cover 21, and the other end is connected to the rear end of the agent tank 22. The parts 222 are against each other, and a spring 11 is added in the air chamber 7. On the one hand, the stability of each push stroke of the piston 32 is improved to ensure that the spraying port 213 sprays the sealing agent evenly and continuously, and the elastic effect of the spring 11 is used to complete the sealing. After the spraying agent is applied, it is beneficial fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com