Control method of eliminating static rolling torque in band and strip rolling mill

A control method and technology for eliminating belts, which are applied in the driving device for metal rolling mills, metal rolling, roll speed control, etc., can solve the problems of heavy equipment maintenance workload, reduced production efficiency, shortened service life, etc. The effect of equipment maintenance workload, eliminating static rolling torque and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

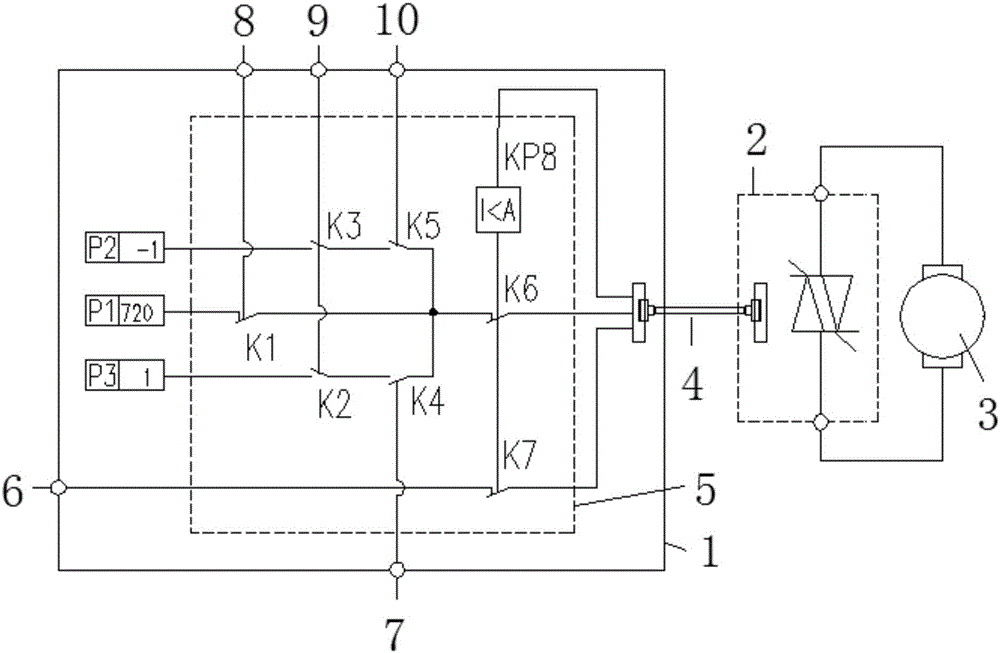

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] The hardware structure that the inventive method adopts is, comprises PLC programmable controller 1, and PLC programmable controller 1 is connected with DC speed controller 2 signals by communication cable 4, and DC speed controller 2 is connected with rolling mill main motor 3 signals The PLC programmable controller 1 is also provided with a rolling mill start signal port 6, a rolling mill stop signal port 8, an unloading signal port 9, a forward rolling signal port 10 and a reverse rolling signal port 7;

[0020] Among them, the existing hardware used includes: PLC programmable controller 1, DC speed controller 2, rolling mill main motor 3, communication cable 4, rolling mill start signal port 6, rolling mill stop signal port 8, forward rolling signal port 10. Reverse rolling signal port 7,

[0021] The newly added hardware is unloa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com