A robotic spiral hole-making method for laminated structures of aircraft fuselages

A technology for a laminated structure and aircraft fuselage, which is applied in the directions of manufacturing tools, milling machine equipment details, metal processing equipment, etc., can solve the problems of unfavorable terminal hole-making actuators, difficult to use, and low efficiency in processing laminated structures. Achieve the effect of improving hole-making efficiency, suppressing exciting force and reducing tool wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

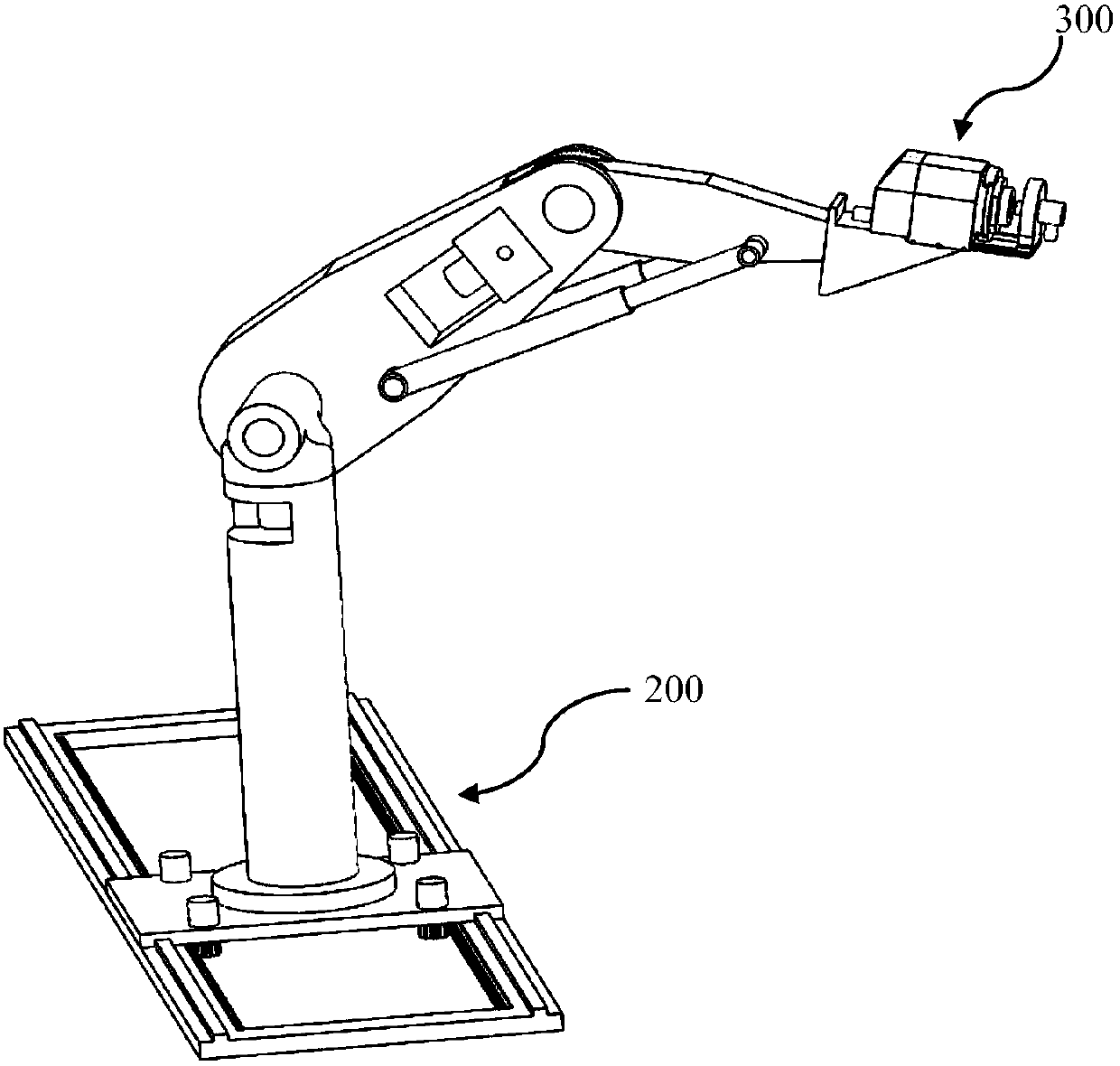

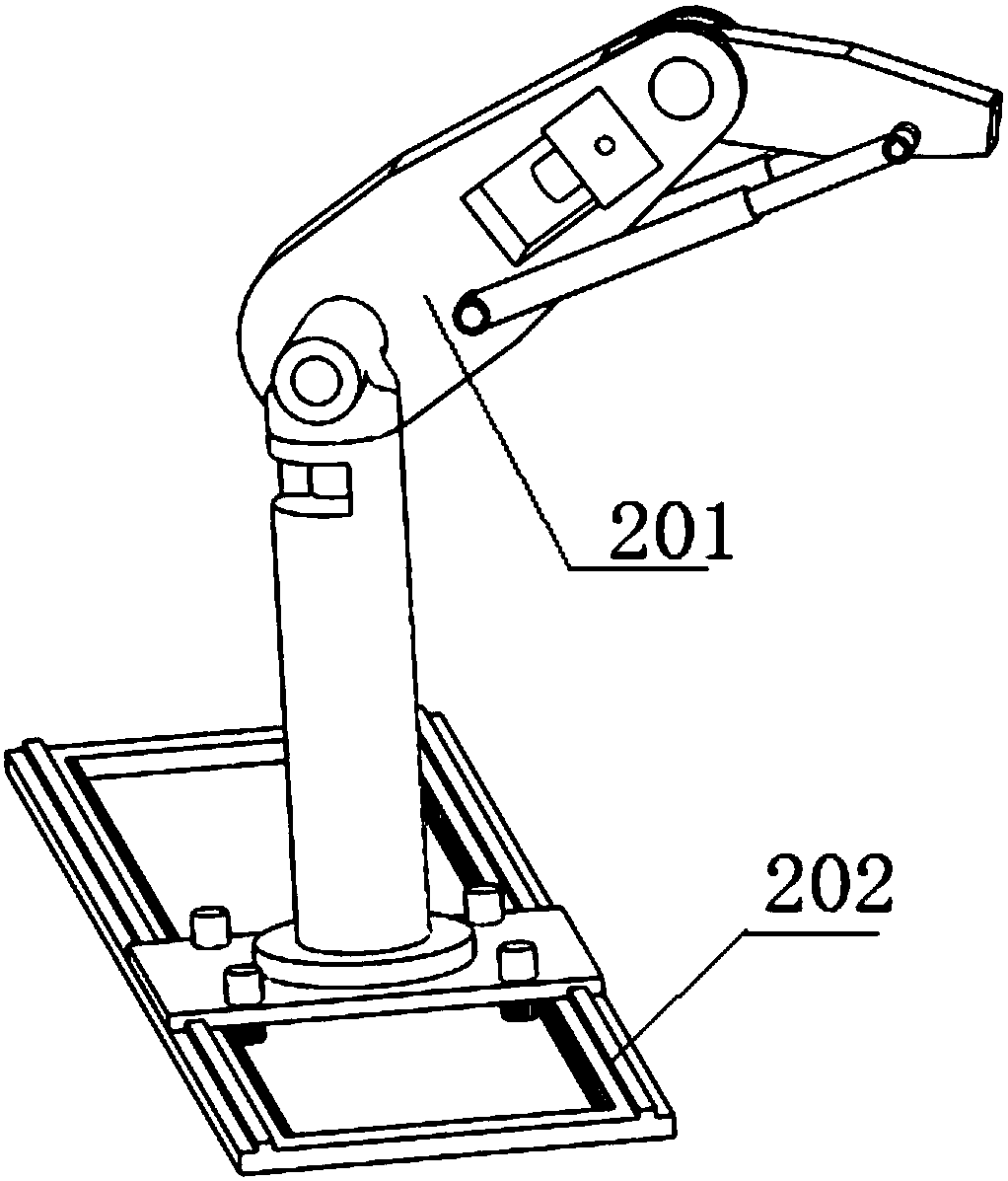

[0023] Such as figure 1 As shown, a method for robotized spiral hole making for aircraft fuselage stacked structure, which is applied to a robotized screw hole making system, includes the following steps:

[0024] (1) According to the diameter of the tool and the diameter of the hole to be made on the laminated structure of the fuselage, adjust the tool revolution radius e to the required setting value;

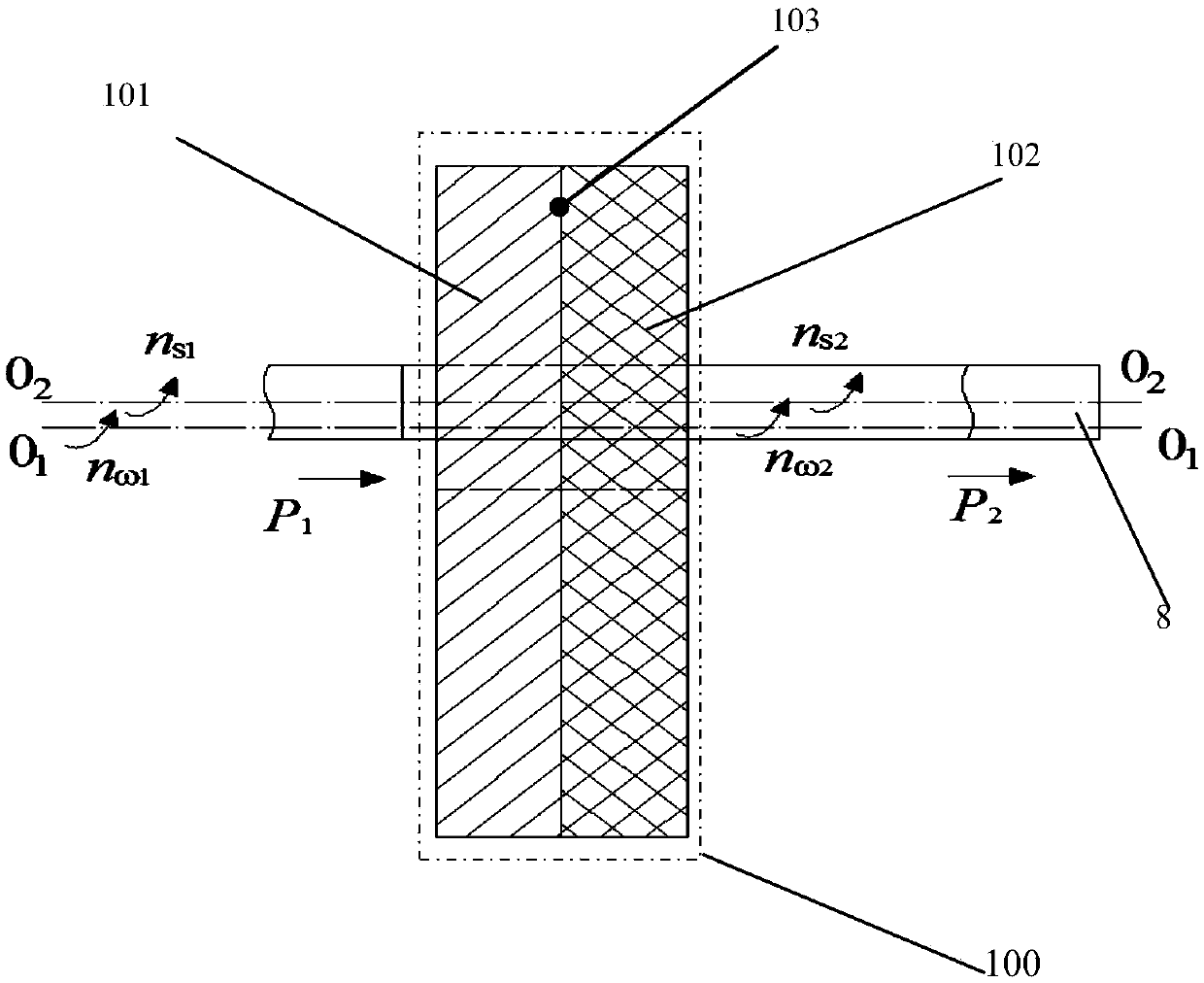

[0025] (2) Tool 8 to match the high rotation speed n of the top layer component material s1 , low revolution speed n ω1 and large feed pitch P 1 , performing spiral drilling on the top layer member 101;

[0026] (3) At the interface 103 of the stacked structure of the fuselage, the high rotation speed, low revolution speed, and large feed pitch of the tool are adjusted by n s1 , n ω1 ,P 1 tuned to match the n of the underlying component material s2 , n ω2 , P 2 ;

[0027] (4) Tool to match the high rotation speed n of the underlying component material s2 , low revo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com