Two-way switching type non-fluctuation screen exchanger

A screen changer and no fluctuation technology, applied in the field of screen changer, can solve problems such as uneven discharge, increased head pressure, raw material loss, etc., and achieve the effects of precise control, reduced material leakage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

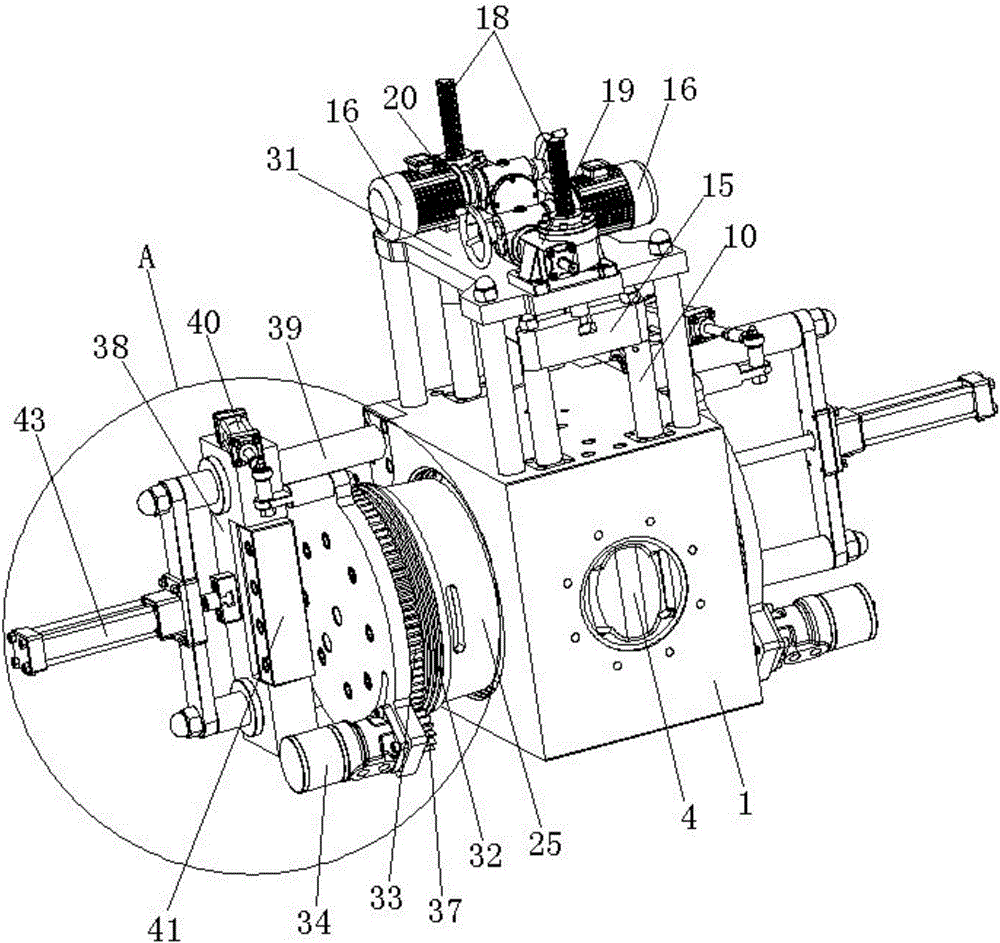

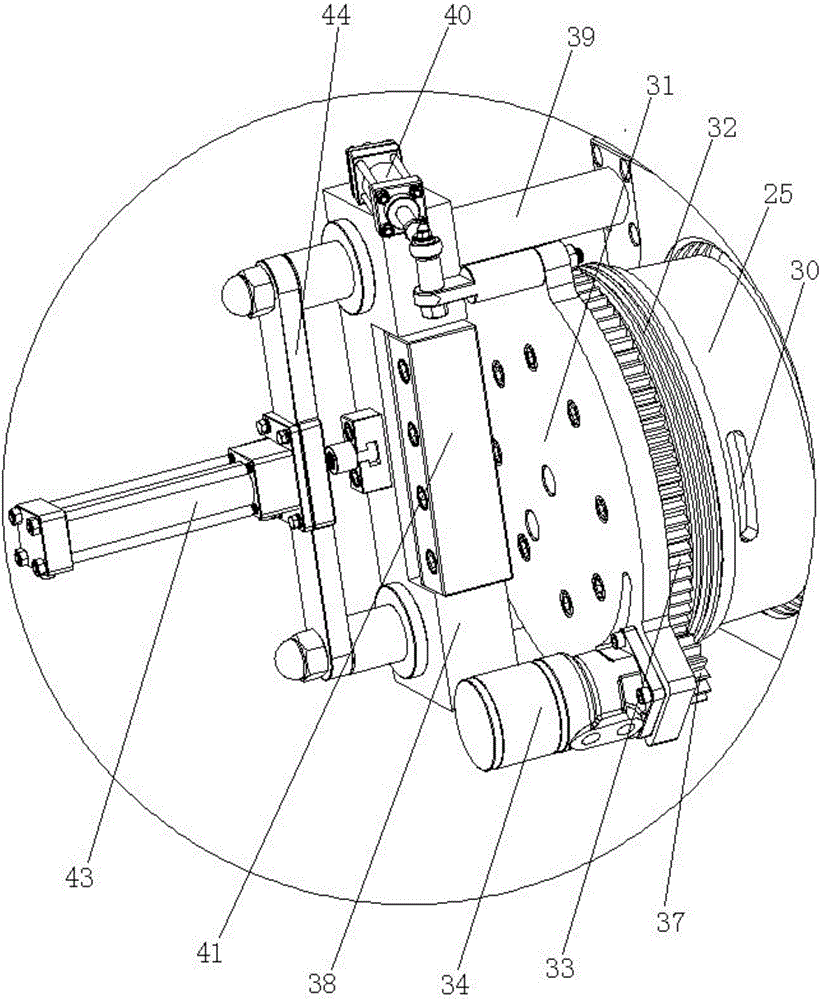

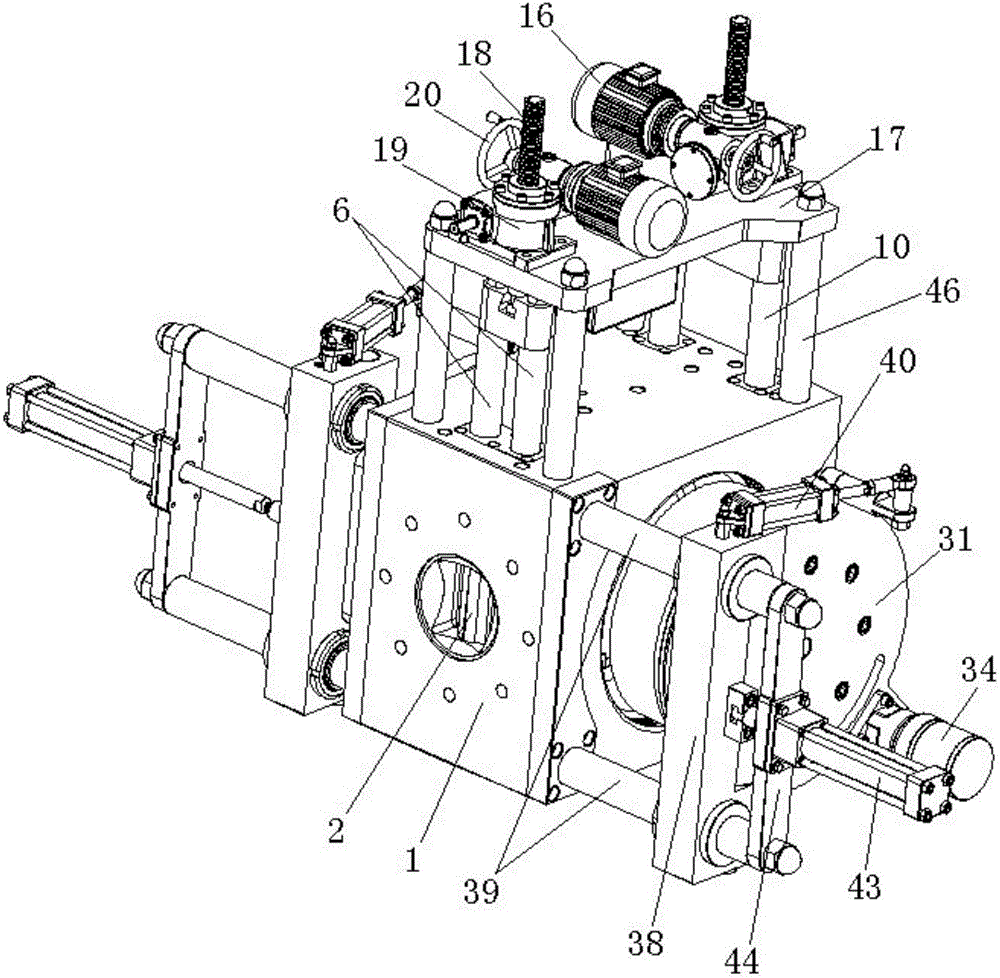

[0057] A two-way switchable waveless screen changer, comprising a screen changer box 1, two sets of mutually independent filter mechanisms are arranged in the screen changer box 1, and the front end of the screen changer box is provided with a general inlet The feed port 2 and the total feed port 2 are divided into two feed channels 3, and each feed channel 3 is respectively connected with a set of filter mechanisms. The discharge port 4 is also divided into two discharge passages 5, and each discharge passage 5 is respectively connected with a set of filter mechanisms;

[0058] A group of feed control valve assemblies are provided on the two feed passages 3, and the feed control valve assembly includes a feed valve stem 6, a rod sleeve a7, and a driving mechanism a that drives the feed valve stem 6 to move up and down. The rod sleeve a7 is set out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com