Material discharging control system of novel FDM printer

A technology of control system and printer, which is applied in the direction of additive processing, etc., can solve the problems of uneven discharge wire, FDM printer is not intelligent, etc., to achieve the effect of optimizing space, ensuring molding quality, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

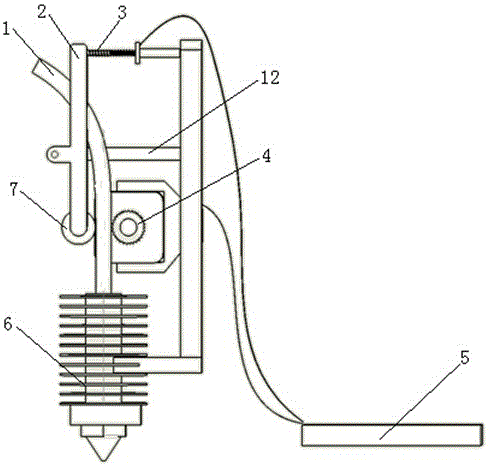

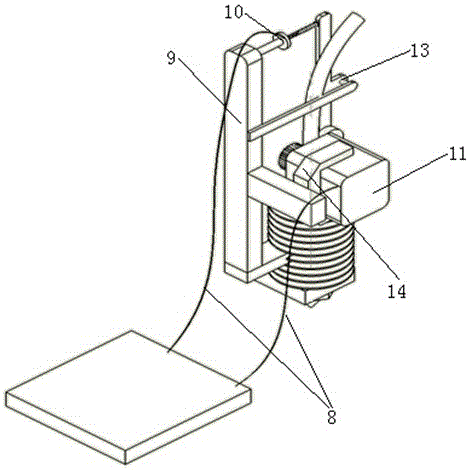

[0029] ginseng figure 1 , figure 2 as shown, figure 1 It is a schematic diagram of the front view of the new FDM printer discharge control system provided by the present invention, figure 2 It is a schematic diagram of a 45-degree top view at the right rear of the new FDM printer discharge control system provided by the present invention. The new FDM printer output control system provided by the present invention includes a wire 1, a connecting rod 2, a spring 3, an extrusion gear 4, a circuit board 5, a nozzle 6, an extrusion roller 7, a wire 8, a bracket 9, a pressure sensor 10, Extrusion motor 11, fixed rod 12, bearing pin 13, motor support 14.

[0030] Wherein, the bottom end of connecting rod 2 is provided with extruding roller 7, and the top is connected with the input end of pressure sensor 10 by spring 3, and the middle part of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com