The anti-wrinkle method of the new woven bag cutting and sewing all-in-one machine for preventing the inner bag from wrinkling

A woven bag and all-in-one machine technology, which is applied to bag making operations, paper/cardboard containers, containers, etc., can solve the problems of inner bags being triangularly folded, not completely cleared, and materials not loaded to the bottom, etc., and achieve the effect of even side lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

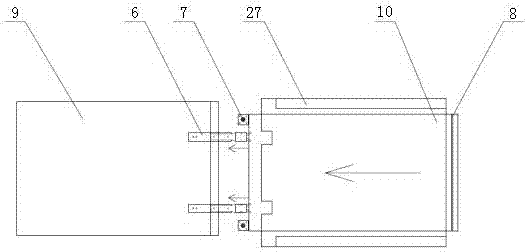

[0017] Refer to attached figure 1 In the prior art shown, the original inner membrane machine cuts the inner membrane bag after making the inner membrane bag, and transports the inner membrane bag to the bridge conveying platform. The hot sealing position of the inner membrane bag is at the front, and the inner membrane machine clamps Hold the bottom of the inner membrane bag and pull the inner membrane bag into the bottom of the outer bag, so there is a problem of knuckles at the bottom of the inner membrane bag.

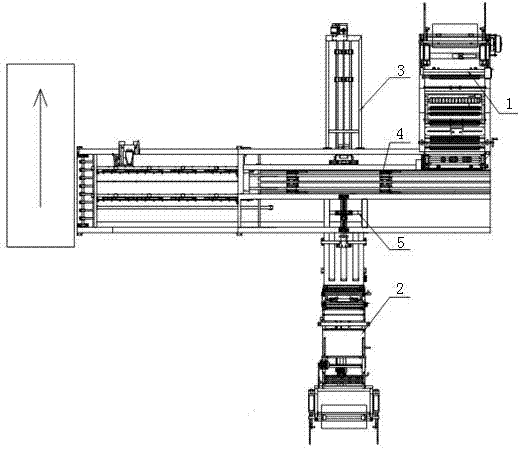

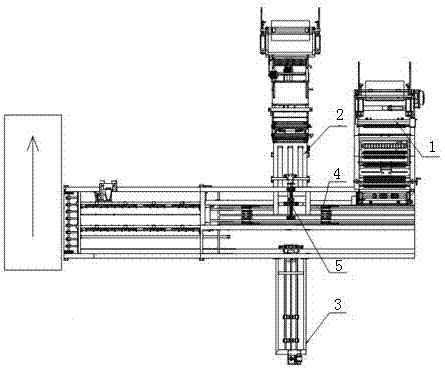

[0018] Refer to attached Figure 2-5 A new type of woven bag cutting and sleeve sewing integrated machine for preventing inner bag wrinkling shown includes an outer bag making machine 1, an inner film p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com