A method for treating reverse osmosis concentrated water by catalytic oxidation using heterogeneous Fenton reaction

A reverse osmosis concentrated water, catalytic oxidation technology, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of catalyst loss, reduced treatment effect, low utilization efficiency, etc., to reduce COD value and chromaticity, process is easy to control, and the effect of stable and standard discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

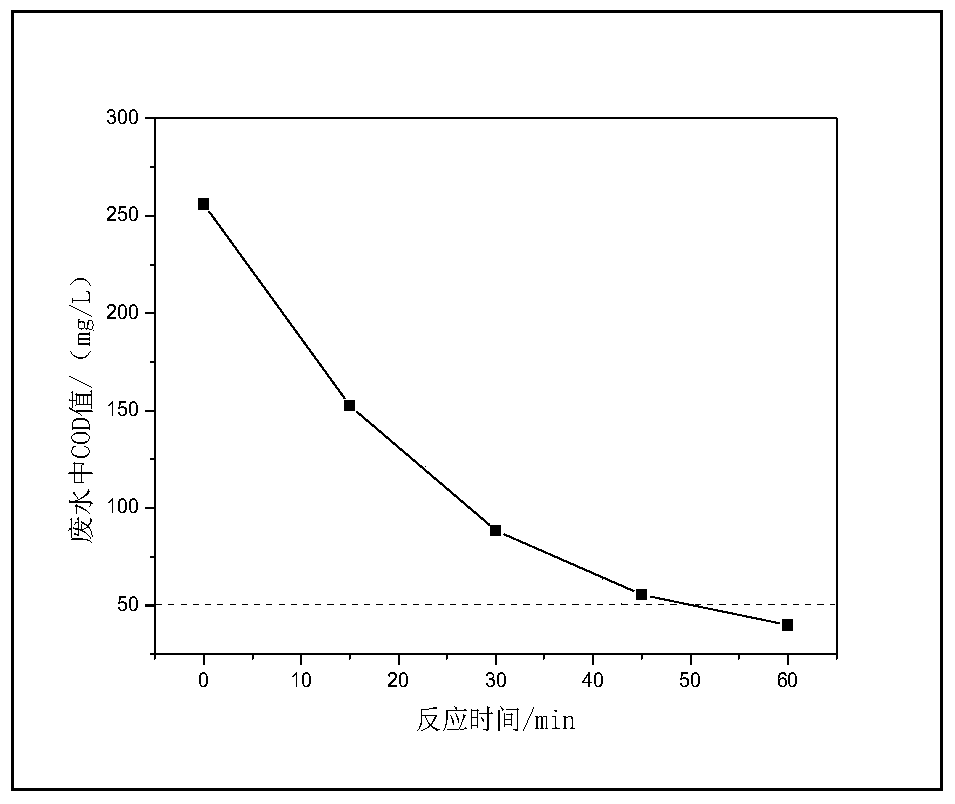

Embodiment 1

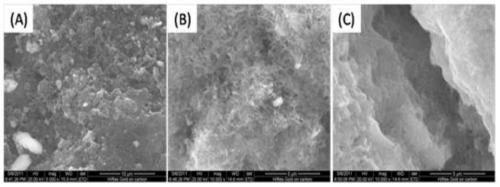

[0037] The preparation method of the supported transition metal oxide catalyst is as follows: 1) Carrier pretreatment: add 1.0% silica sol by mass percentage to 200 mesh powdered activated carbon, rotationally mold, dry at 100°C for 24h, and obtain a diameter of 2.0-4.0mm 2) catalyst preparation: ①, weigh 27.80g FeSO 4 ·7H 2 O, 3.75g CuSO 4 ·5H 2 O, 3.23g CoCl 2 ·6H 2 O, 1.97gMnSO 4 ·H 2 0, add 1000mL distilled water, make it dissolve fully under stirring; Nitrogen is exposed to the mixed solution for 20min; 0.005 times, the pH value of the solution was adjusted to 9.0 with ammonia water, and the solution gradually changed from yellow-green to dark green; ③. Place 20.0 g of the pretreated carrier in the cathode area of the electrolytic cell, and then add the complexed mixed solution In the electrolytic cell, the cathode and anode of the electrolytic cell are spectrally pure graphite electrodes; ④. Place the electrolytic cell in a water bath, control the temperature at...

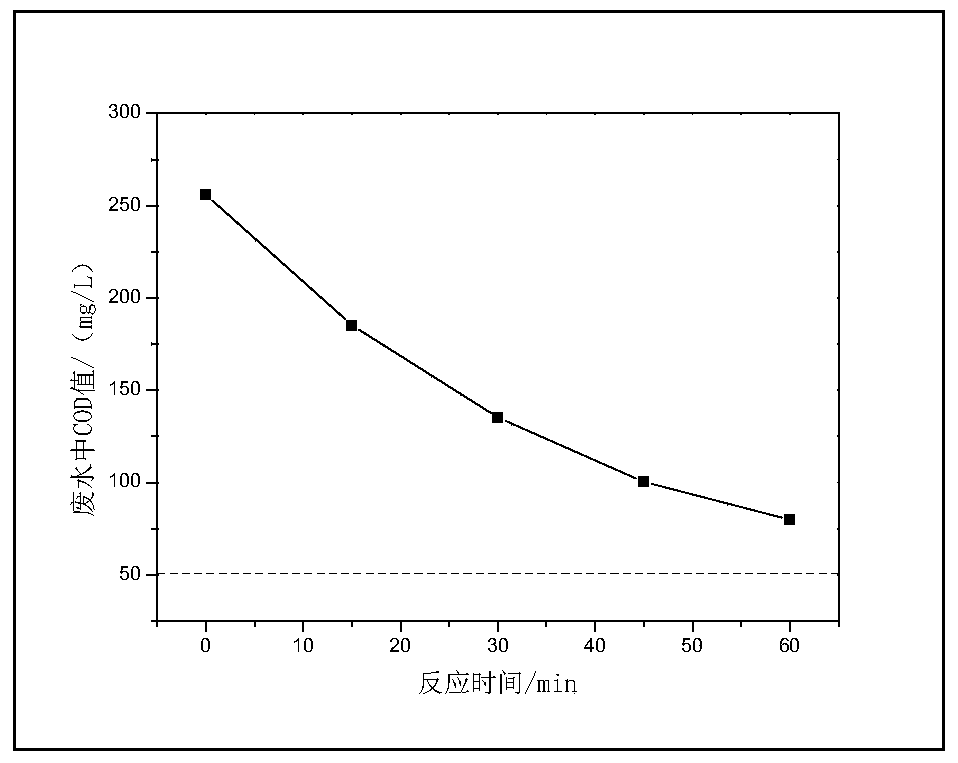

Embodiment 2

[0044] The preparation method of the supported transition metal oxide catalyst is as follows: 1) Carrier pretreatment: add 1.5% silica sol by mass percentage to 250 mesh powdered activated carbon, rotate molding, and dry at 100°C for 22 hours to obtain a diameter of 1.0-3.0mm 2) Catalyst preparation: ①, weigh 29.81g FeCl 2 4H 2 O, 7.32gCu(NO 3 ) 2 ·3H 2 O, 6.15gCoSO 4 ·7H 2 O, 5.86gMn(NO 3 ) 2 4H 2 0, add 1000mL distilled water, stir to make it fully dissolved; nitrogen exposure to the mixed solution for 30min; ②, add complexing agent sodium citrate aqueous solution to the mixed solution, the molar number of complexing agent is 0.0075 of the molar number of ferrous chloride times, the pH value of the solution was adjusted to 8.5 with ammonia water, and the solution gradually changed from yellow-green to dark green; ③, 25.0 g of the pretreated carrier was placed in the cathode area of the electrolytic cell, and then the complexed mixed solution was added to the In th...

Embodiment 3

[0050] The preparation method of the supported transition metal oxide catalyst is as follows: 1) Carrier pretreatment: adding 2.0% silica sol by mass percentage into 300 mesh molecular sieve MCM-41, rotating molding, drying at 90°C for 20h, and obtaining a 2.5mm spherical particles for standby; 2) Catalyst preparation: ①, weigh 37.43gFe(NO 3 ) 2 ·6H 2 O, 4.92gCuSO 4 ·5H 2 O, 4.68gCoCl 2 ·6H 2 O, 5.13gMn(NO 3 ) 2 4H 2 0, add 1000mL distilled water, stir to make it fully dissolved; Nitrogen is exposed to the mixed solution for 25min; ②, add the aqueous solution of complexing agent to the mixed solution, the complexing agent is a mixture of ethylenediaminetetraacetic acid and sodium fluoride (mass Ratio 1:1:), the number of moles of the complexing agent is 0.006 times the number of moles of ferrous nitrate, the pH value of the solution is adjusted to 9.0 with ammonia water, and the solution gradually changes from yellow-green to dark green; ③, pretreated carrier 25.0g is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com