Material distribution system of deep dewatering machine for sludge

A deep dewatering and distribution system technology, applied in water/sludge/sewage treatment, sludge treatment, water/sewage treatment, etc., can solve the problems of uneven distribution, unstable sludge dewatering effect, vibration, etc., to ensure The effect of stable operation, stable and reliable processing capacity, and prolonged service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The purpose of the present invention will be further described in detail through specific examples below, and the examples cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following examples.

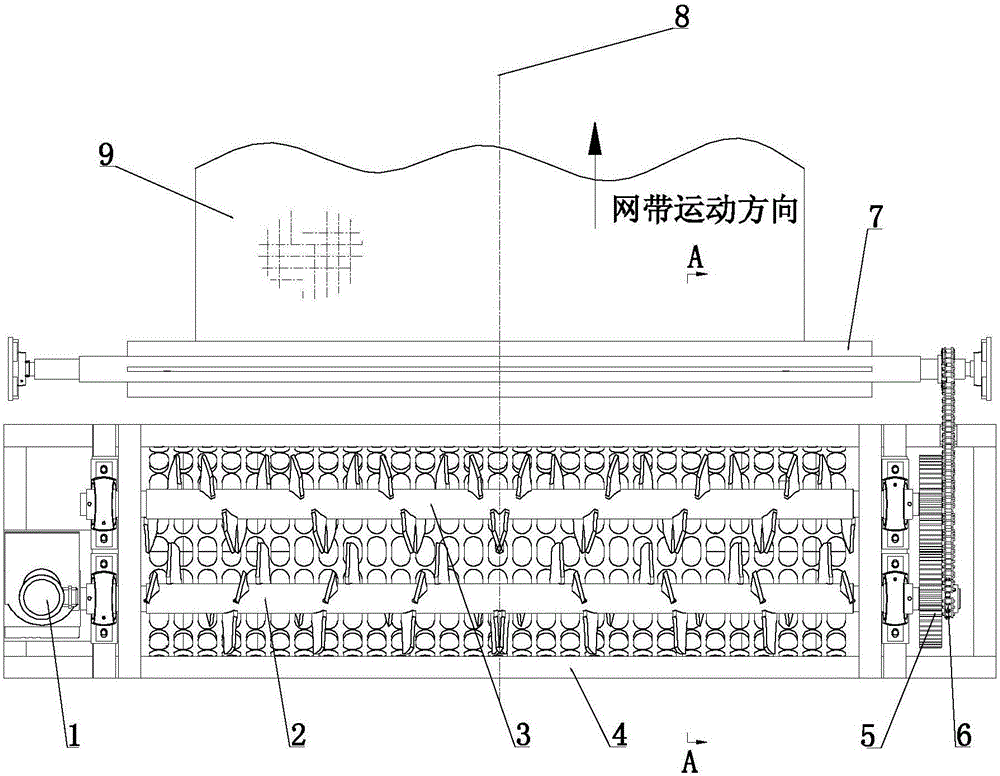

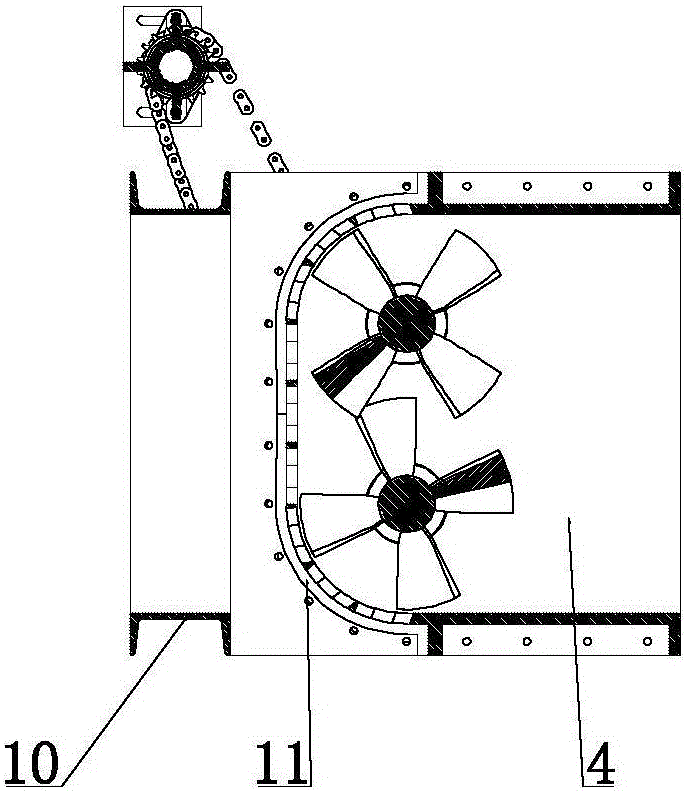

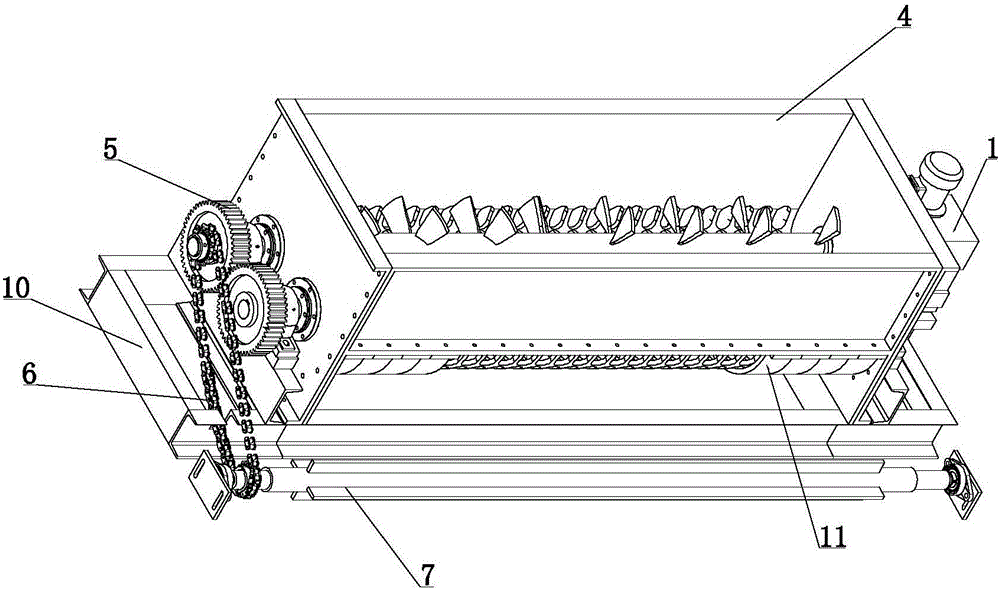

[0021] Such as Figure 1 to Figure 6 As shown, a distributing system of a deep sludge dewatering machine includes a base 10 and a hopper 4 fixedly arranged on the base 10, and the active screw with the same length of the helical part and the opposite direction is installed in the hopper 4 in parallel rotation. 2 and the driven screw 3, the two ends of the driving screw 2 and the driven screw 3 are rotatably supported by the side plates and bearings of the hopper 4, and the side plates are fixed on the mounting screw holes 16 of the hopper side plates at both ends of the hopper 4 by screws , the helical direction on the driving screw 2 and the driven screw 3 is reversely set with the centerline 8 as the line of sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com