Washing machine and deceleration clutch for same

A deceleration clutch and washing machine technology, applied in the field of washing machines, can solve problems such as poor overrunning clutch, large vibration of washing machines, failure of one-way bearings, etc., and achieve the effects of simple and reliable structure, improved cleaning ratio, and improved carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

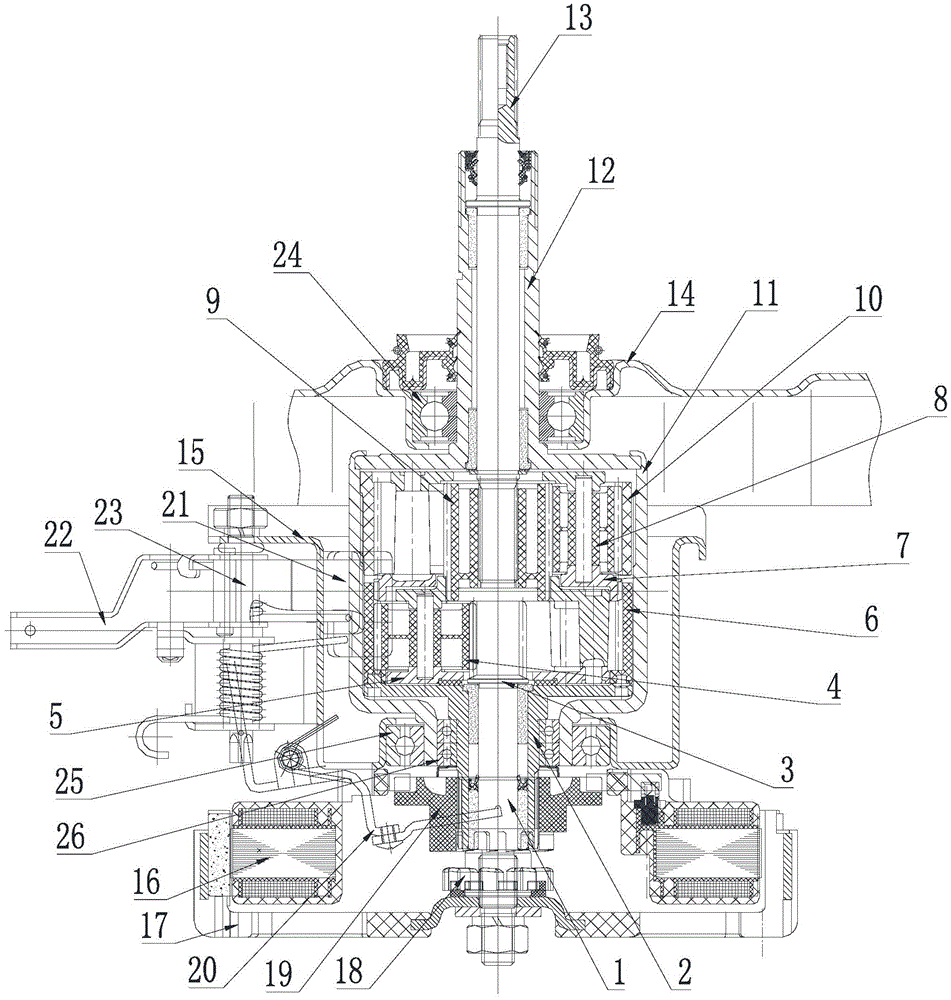

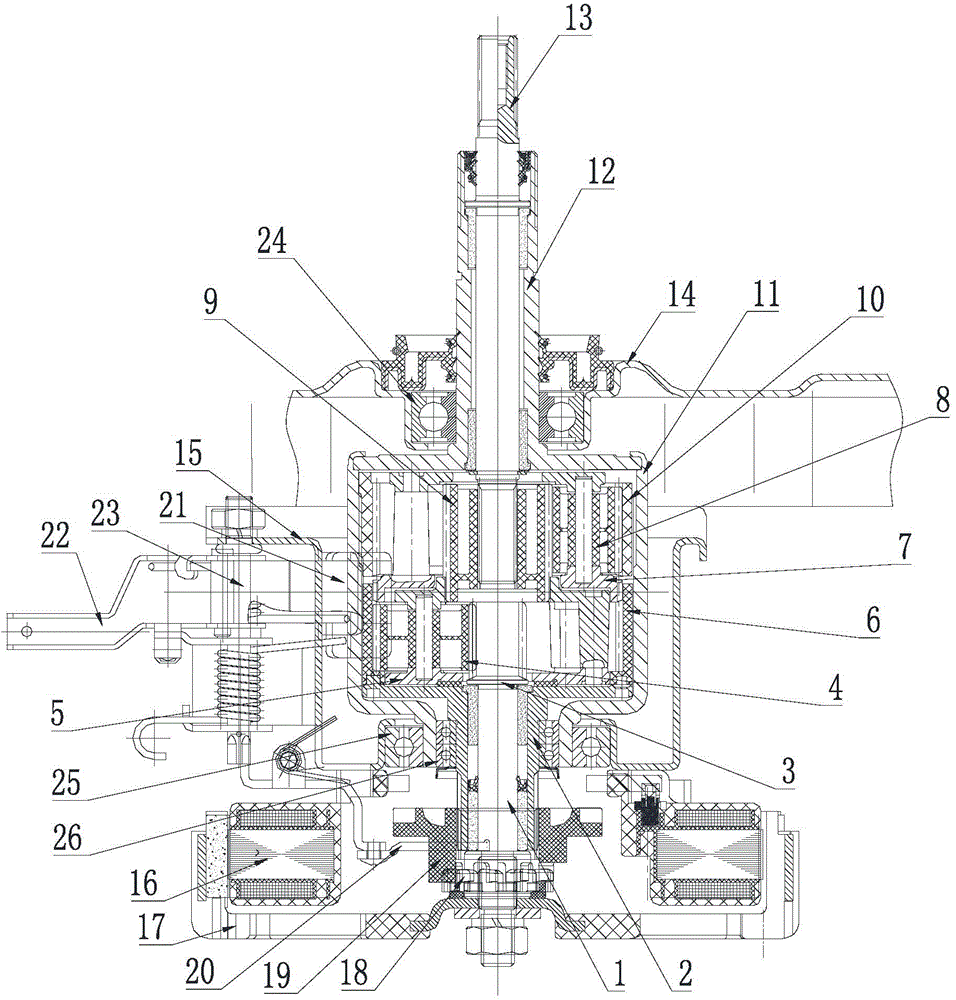

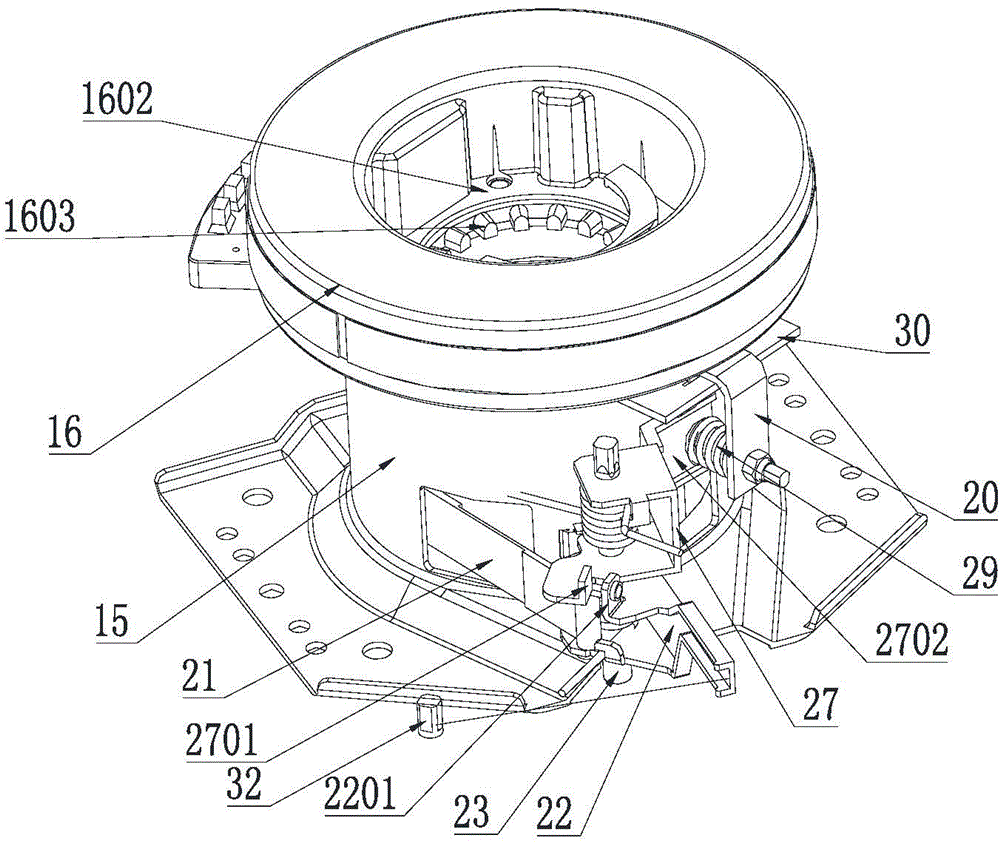

[0039] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, a deceleration clutch for a washing machine according to the present invention at least includes a housing, a brake wheel 11 located in the housing, and a wheel train located in the brake wheel 11. The lower part of the housing is fixedly connected to a direct drive motor, and the direct drive The cavity of the motor stator 16 is provided with a clutch sleeve 19 that can slide up and down, and the clutch sleeve 19 slides up and down to connect with the torque transmission sleeve 18 and the fixed sleeve respectively to realize dehydration and washing. The clutch sleeve 19 is driven by a shift fork 20, There is a gap between the inner side wall of the stator 16 and the outer side wall of the clutch shaft sleeve 19, and the stator 16 is located at the top of the gap and is provided with a gap 1601, and the shift fork 20 extends into the gap 1601, at least par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com