Quick positioning and verticality-adjusting device for large-diameter steel-pipe upright column pile and construction method

A steel pipe column with a large diameter technology, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems that the vertical adjustment progress cannot match the pile foundation construction, the large positioning deviation of the vertical adjustment device, and the construction personnel's difficulty in operation, etc., to achieve The structure of the device is easy to obtain, the degree of adjustment is large, and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention are given below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in very simplified form and use imprecise ratios, which are only used for the purpose of conveniently and clearly assisting in describing the embodiments of the present invention.

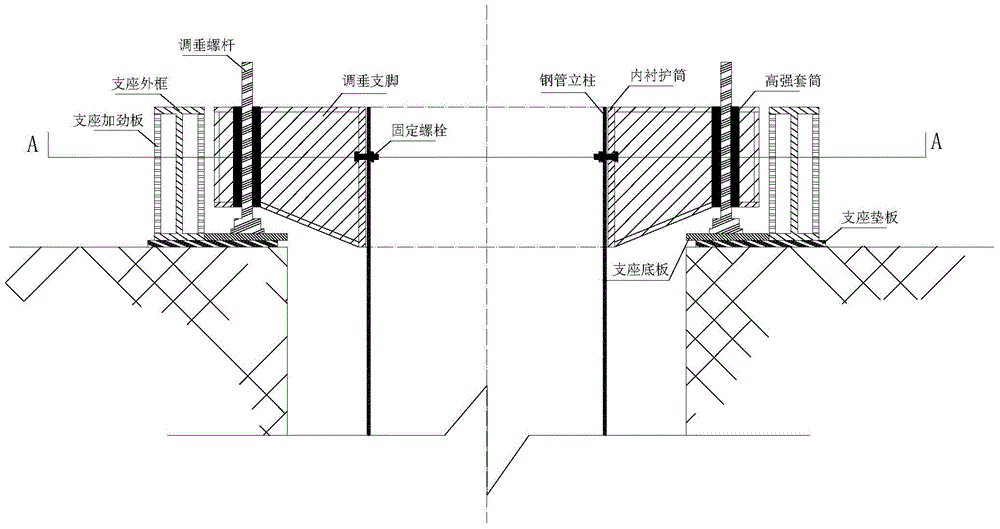

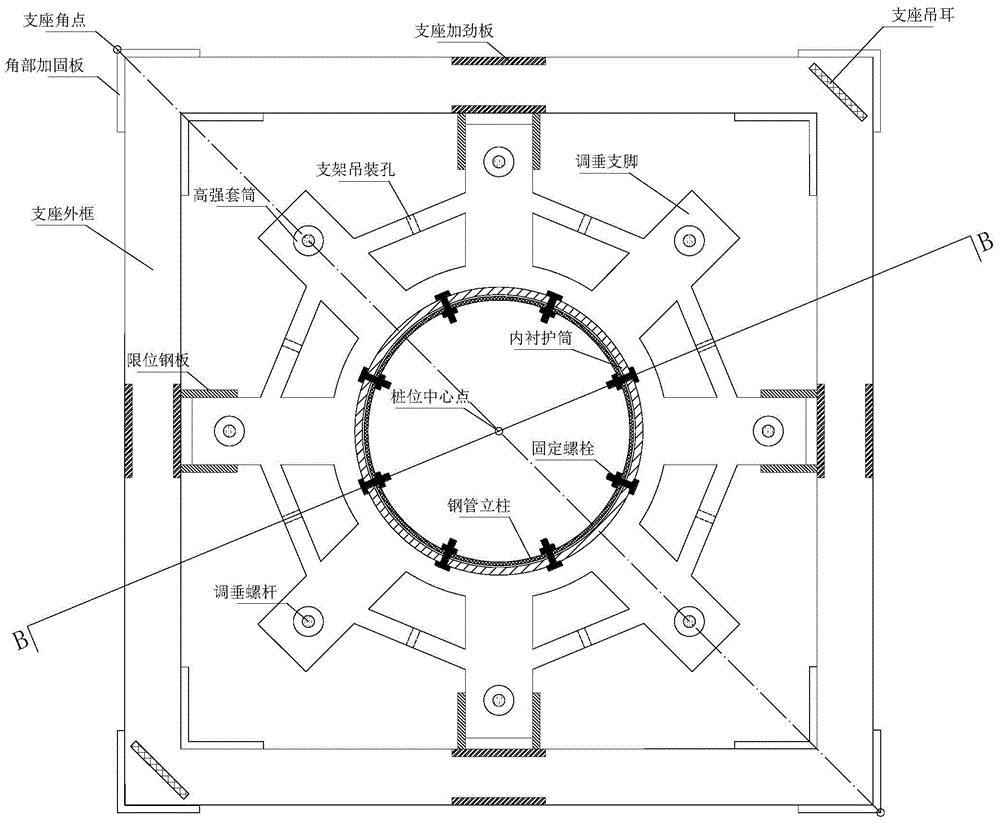

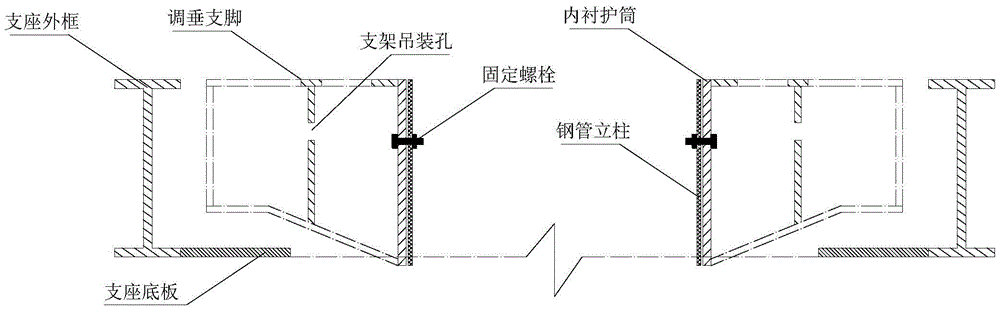

[0031] Please refer to Figure 1 to Figure 5 , figure 1 Shown is a schematic structural diagram of a large-diameter steel pipe column pile quick positioning vertical adjustment device according to a preferred embodiment of the present invention, figure 2 shown as figure 1 The schematic diagram of the cross-sectional structure according to the A-A direction in the middle, image 3 shown as figure 2 The schematic diagram of the cross-sectional structure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com