Vertical sludge cleaning equipment and its cleaning method

A cleaning method and technology for cleaning equipment, applied in construction, earth movers/excavators, etc., can solve the problems of expensive equipment, sedimentation sites, large energy consumption of dredging equipment, environmental pollution, etc., and achieve obvious energy saving effect, clean High silting efficiency and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

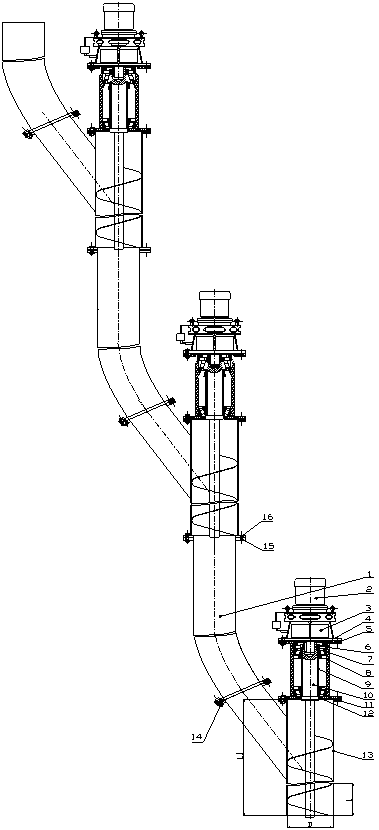

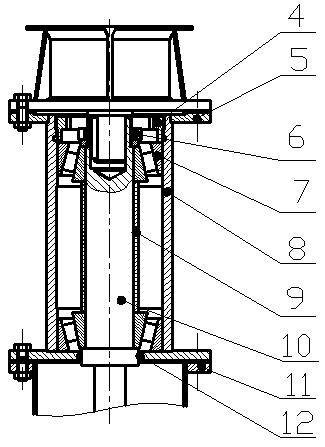

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] like figure 1 As shown, there are multiple screw conveying devices. For the convenience of illustration, the screw conveying devices from bottom to top are named in the order of the first stage, second stage, third stage..., and the structures of the screw conveying devices are the same. Through the first stage The screw conveying type hinged dragon outer casing 13 cuts into the silted soil to cut the soil, and then the spiral hinged dragon shaft 10 with spiral blades rotates to push the soil upwards, and then continues to move upwards through the conveying pipeline 1. When the soil moves up to the second When the first-stage screw conveyor type auger is in the outer casing, the second-stage screw conveyor type auger continues to push the soil upwards, so that the third and fourth-stage screw conveyor type augers continue to pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com