Anti-breakage anchor rod

A bolt and tail rod technology, which is applied in the installation of bolts, construction, mining equipment, etc., can solve the problems of bolt shear damage, failure, engineering loss, etc., and achieve the effect of buffering, governance and effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

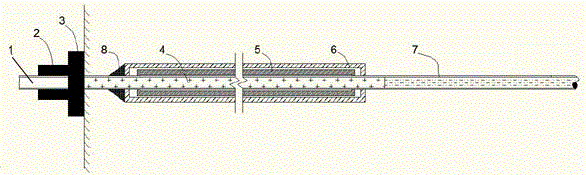

[0012] Such as figure 1 Shown, the present invention comprises anchor rod 7, and the end of anchor rod tail rod 1 has nut 2 and the steel plate tray 3 that is close to surrounding rock wall, and nut 2 presses down steel plate tray 3, and the middle section of anchor rod 7 is anchor rod The steel bar 4 of the free section is covered with a sleeve 5 with built-in thread on the steel bar 4 of the free section of the anchor rod.

[0013] Such as figure 1 As shown, an outer sleeve 6 is sheathed on the periphery of the sleeve 5, and the outer sleeve 6 and the steel bar 4 of the free section of the anchor rod are connected and fixed through a welding zone 8. The main functions of the outer sleeve 6 are as follows: 1. When the anchor rod steel bar is not broken, there is cohesive force between the outer sleeve 6 and the grouting body, and this cohesive force can sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com