Common Rail Diesel Engine Fuel Injection Control System

A control system and diesel engine technology, applied in engine control, fuel injection control, electrical control, etc., can solve the problems of complex control logic of the main control chip, lack of perfect fault diagnosis strategy, failure to realize fault type judgment, etc., to achieve fault diagnosis and The effect of perfect hardware protection strategy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

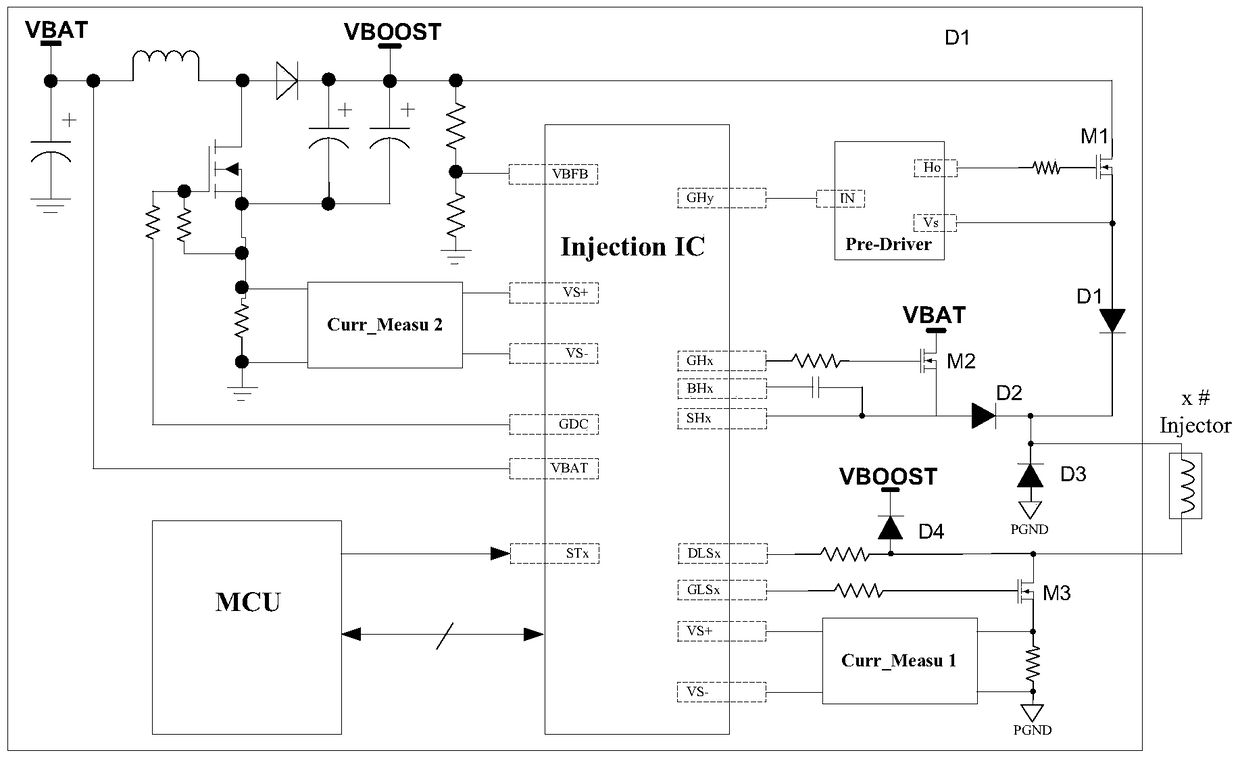

[0048] Common rail diesel fuel injection control system, such as figure 1 As shown, including boost circuit module (BOOST DC_DC), fuel injection control module (Injection IC), pre-driver module (Pre_Driver IC), main processor (MCU);

[0049] The main processor (MCU) judges the current injection task, and sends the cylinder sequence signal STx to the fuel injection control module (Injection IC);

[0050] The step-up circuit module is used for DC voltage conversion, and boosts the battery voltage VBAT to fuel injection drive high voltage VBOOST;

[0051] The fuel injector (x#Injector) of the X cylinder, the high side is connected to the lower end of the first power switch tube M1 and the lower end of the second power switch tube M2, and the low side is connected to the upper end of the third power switch tube M3; the X cylinder Any cylinder of a diesel engine;

[0052] The first power switch tube M1 is connected to the fuel injection drive high voltage VBOOST at the upper end;...

Embodiment 2

[0072] Based on the common-rail diesel engine fuel injection control system of Embodiment 1, the common-rail diesel engine fuel injection control system further includes a first current sampling module Curr_mesau1 and a second current sampling module Curr_mesau2;

[0073] The first current sampling module Curr_mesau1 is used to detect the current Curr1 between the lower end of the third power switch tube M3 and the ground;

[0074] The second current sampling module Curr_mesau2 is used to detect the current Curr2 at the upper end of the first power switch tube M1.

[0075] The first current sampling module Curr_mesau1 and the second current sampling module Curr_mesau2 can be integrated in the fuel injection control module (Injection IC), or can be realized through an external operational amplifier circuit.

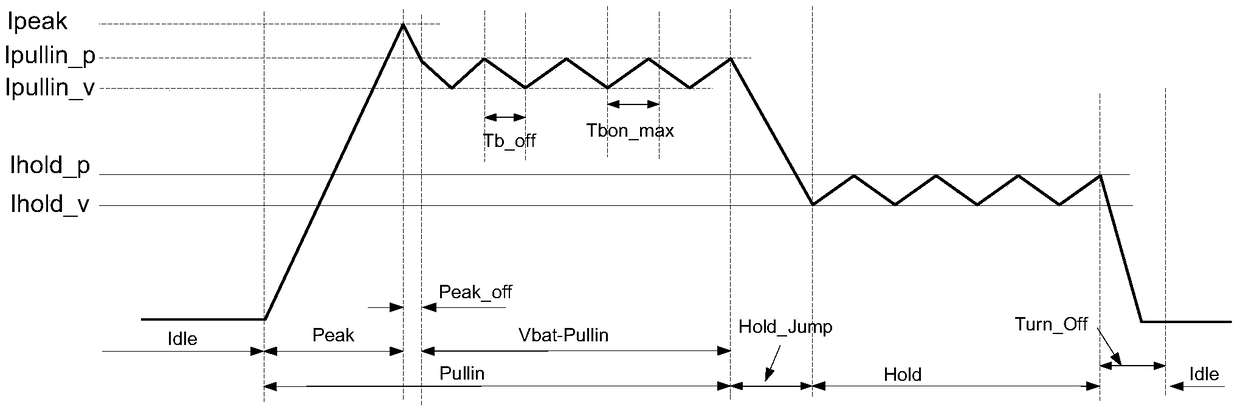

[0076] Such as figure 2 As shown, the main injection current waveform of the injector of cylinder X consists of the opening acceleration phase Peak, the transitional shu...

Embodiment 3

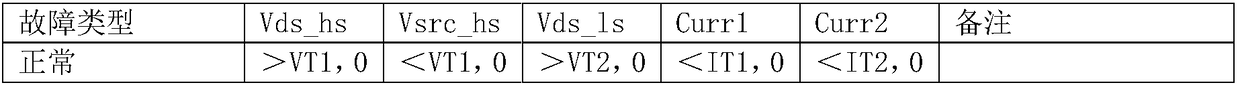

[0090] Based on the common rail diesel engine fuel injection control system of Embodiment 2, the fuel injection control module, according to the voltage Vds_hs between the upper and lower ends of the second power switch tube M2, and the voltage Vsrc_hs between the lower end of the second power switch tube M2 and the ground , the voltage Vds_ls between the upper end of the third power switch tube M3 and the ground, the current Curr1 between the lower end of the third power switch tube M3 and the ground detected by the first current sampling module Curr_mesau1, and the first power detected by the second current sampling module Curr_mesau2 The current Curr2 at the upper end of the switch tube M1 is used for fault diagnosis.

[0091] Taking the fuel injector fault diagnosis of cylinder x as an example, the truth tables of basic fault diagnosis and hardware protection strategies are shown in Table 1 to Table 4. Vds_hs is the voltage between the upper and lower ends of the second po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com