Hydroelectric generator

A technology for hydroelectric generators and generators, used in hydroelectric power generation, engine components, machines/engines, etc., can solve problems such as maintenance and maintenance difficulties, waste of resources, single function, etc., to achieve simple design, improve efficiency, and increase power generation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

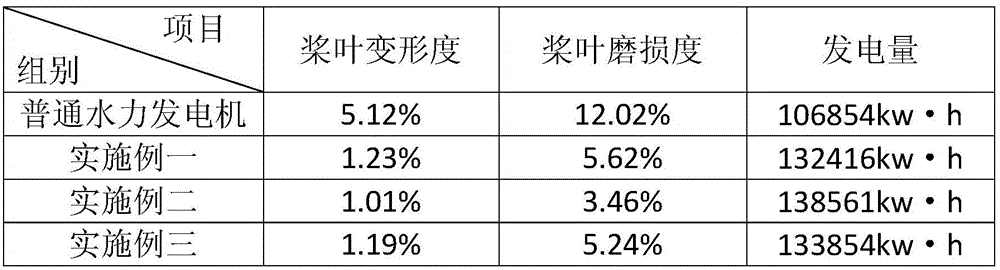

Embodiment 1

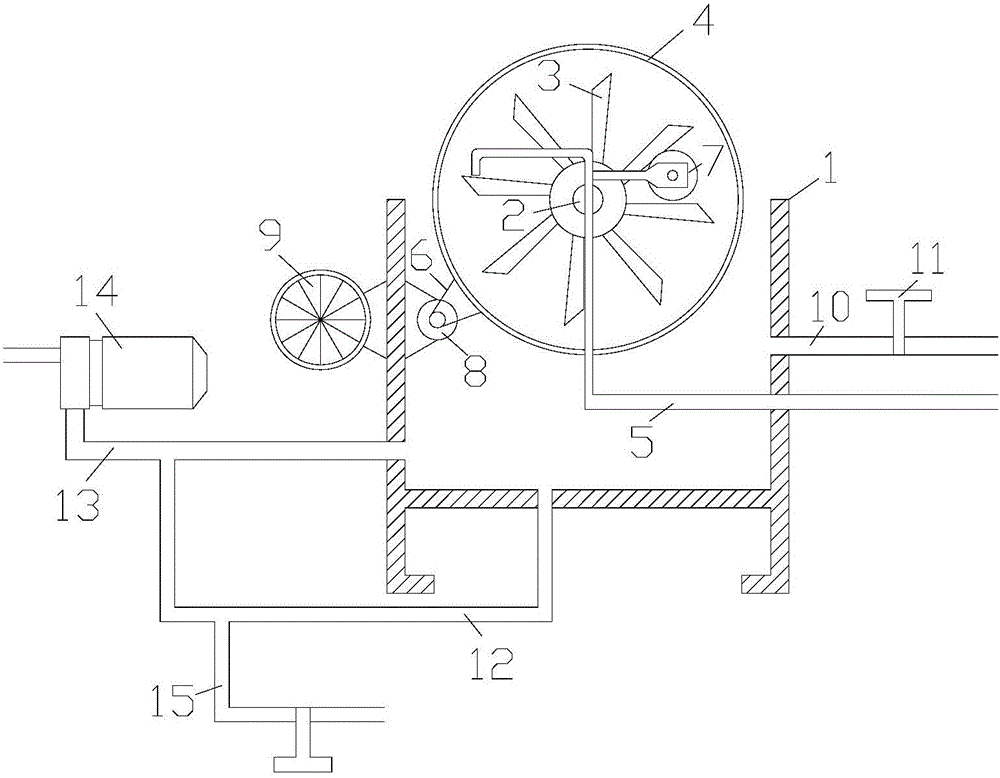

[0022] refer to figure 1 As shown, a hydroelectric generator includes an organic base 1, a rotating shaft 2 and a runner 4, the base 1, the rotating shaft 2 and the runner 4 are connected in sequence, and the rotating shaft 2 is provided with more than one paddle 3, The machine base 1 is set in a concave shape, the machine base 1 is provided with a penetrating water inlet pipe 5, the water inlet pipe 5 is provided with a high-pressure water pump 7, and the machine base 1 is connected with a first suction pipe 10 , shunt pipe 12 and outlet pipe 13, described shunt pipe 12 communicates with outlet pipe 13, is connected with second suction pipe 15 on the described shunt pipe 12, and described first suction pipe 10 and second suction pipe 15 Valves 11 are arranged on each of them, a water pump 14 is arranged on the outlet pipe 13, a generator 9 is arranged outside the base 1, a pulley 8 is arranged between the generator 9 and the runner 4, and the generator 9 and runner 4 all ado...

Embodiment 2

[0036] refer to figure 1 As shown, a hydroelectric generator includes an organic base 1, a rotating shaft 2 and a runner 4, the base 1, the rotating shaft 2 and the runner 4 are connected in sequence, and the rotating shaft 2 is provided with more than one paddle 3, The machine base 1 is set in a concave shape, the machine base 1 is provided with a penetrating water inlet pipe 5, the water inlet pipe 5 is provided with a high-pressure water pump 7, and the machine base 1 is connected with a first suction pipe 10 , shunt pipe 12 and outlet pipe 13, described shunt pipe 12 communicates with outlet pipe 13, is connected with second suction pipe 15 on the described shunt pipe 12, and described first suction pipe 10 and second suction pipe 15 Valves 11 are arranged on each of them, a water pump 14 is arranged on the outlet pipe 13, a generator 9 is arranged outside the base 1, a pulley 8 is arranged between the generator 9 and the runner 4, and the generator 9 and runner 4 all ado...

Embodiment 3

[0050] refer to figure 1 As shown, a hydroelectric generator includes an organic base 1, a rotating shaft 2 and a runner 4, the base 1, the rotating shaft 2 and the runner 4 are connected in sequence, and the rotating shaft 2 is provided with more than one paddle 3, The machine base 1 is set in a concave shape, the machine base 1 is provided with a penetrating water inlet pipe 5, the water inlet pipe 5 is provided with a high-pressure water pump 7, and the machine base 1 is connected with a first suction pipe 10 , shunt pipe 12 and outlet pipe 13, described shunt pipe 12 communicates with outlet pipe 13, is connected with second suction pipe 15 on the described shunt pipe 12, and described first suction pipe 10 and second suction pipe 15 Valves 11 are arranged on each of them, a water pump 14 is arranged on the outlet pipe 13, a generator 9 is arranged outside the base 1, a pulley 8 is arranged between the generator 9 and the runner 4, and the generator 9 and runner 4 all ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com