FRP Centrifugal Fan Blades

A centrifugal fan and glass fiber reinforced plastic technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of difficult quality control, rough appearance, and the dimensional accuracy of fan blades cannot easily meet the design requirements. The effect of saving power consumption, smooth and smooth appearance, and improved operating efficiency of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

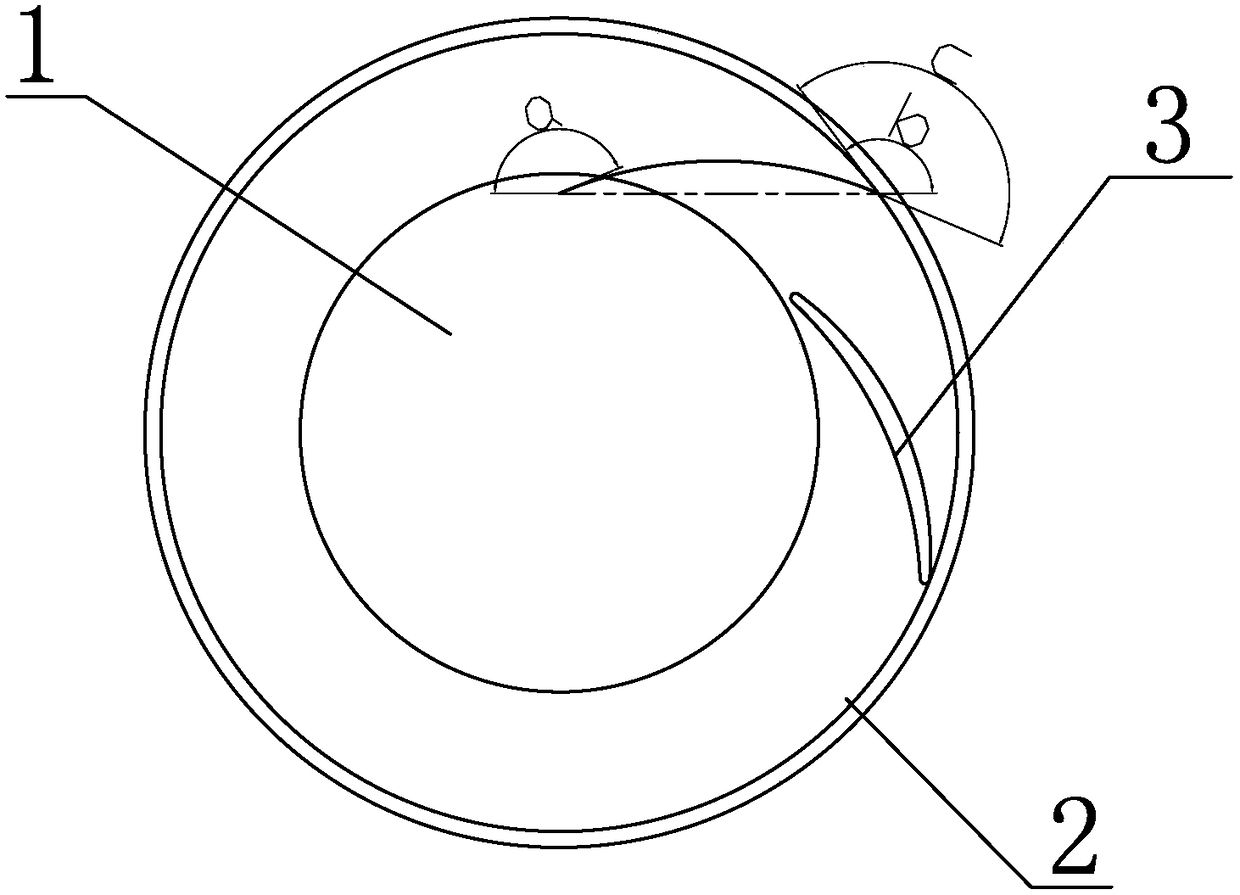

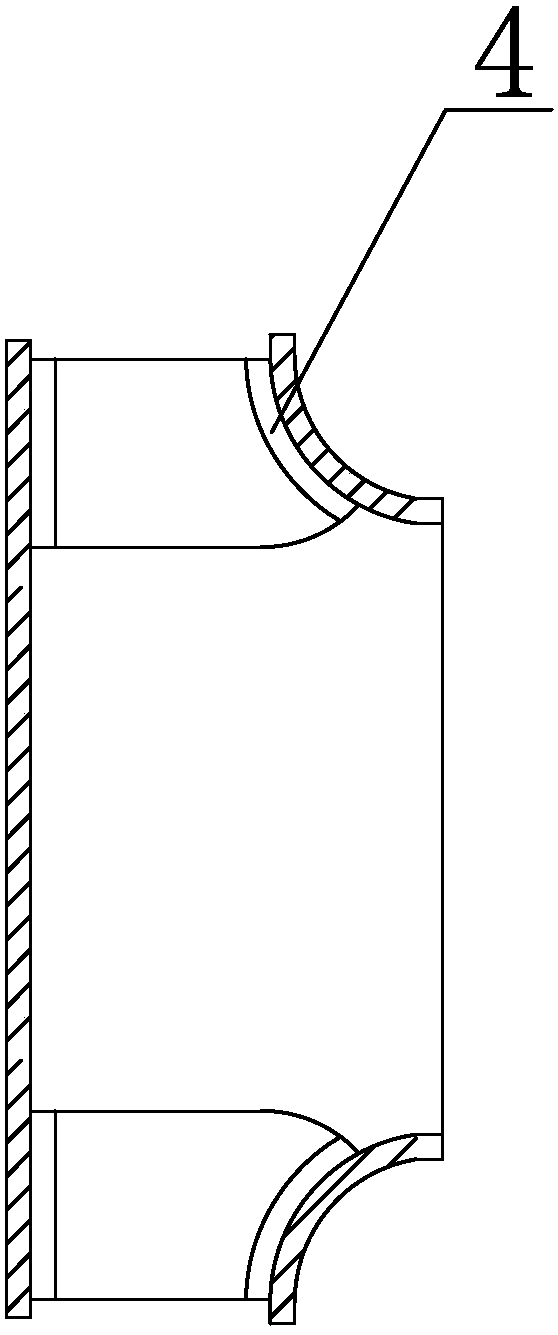

[0013] Such as figure 1 , 2 As shown in , 3, the blade of the FRP centrifugal fan has a structure including a front disk 1 and a rear disk 2, and 12 blades 3 are evenly distributed between the front disk 1 and the rear disk 2. The blades 3 are bow-shaped, and the chord of the circle where the bow is located The supplementary angle a of the angle is 157°, the supplementary angle b of the chord cutting angle of the chord of the inner circle of the back plate 2 passing through the bow is 127°, and the angle between the circle where the bow is located and the intersecting tangent of the inner circle of the back plate 2 is 150°.

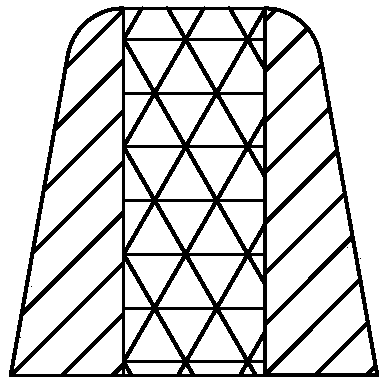

[0014] The cross-section of the blade 3 is an isosceles trapezoid, and the connection between the upper base and the waist of the isosceles trapezoid is rounded.

[0015] The inner side of the front plate 1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com