Ventilation and heat dissipation structure for LED lamp

A technology for ventilation and heat dissipation and LED lamps, which is applied to lighting and heating equipment, cooling/heating devices for lighting devices, lighting devices, etc. The effect of ensuring heat dissipation and improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

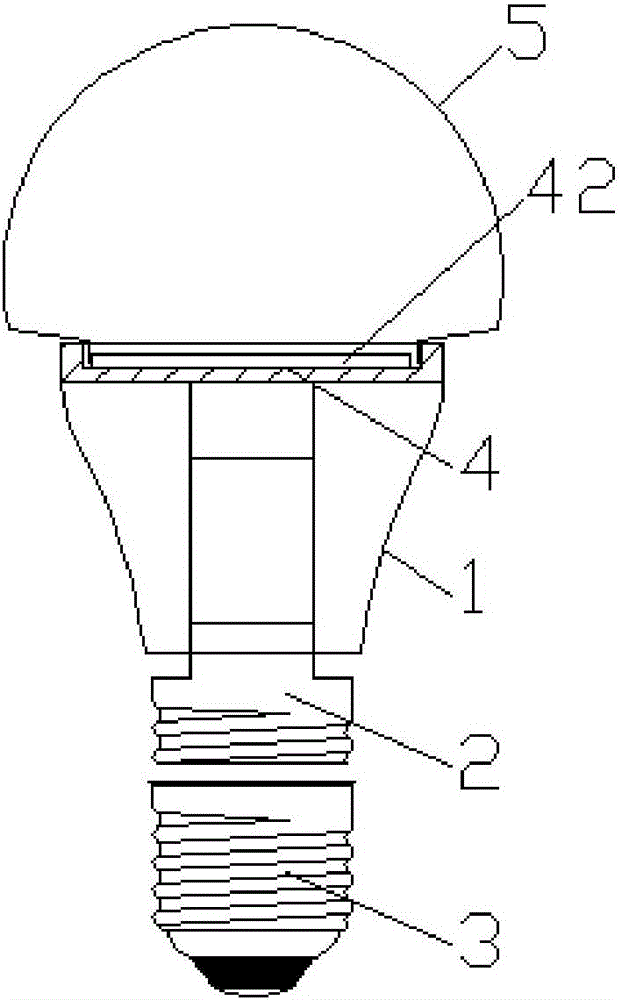

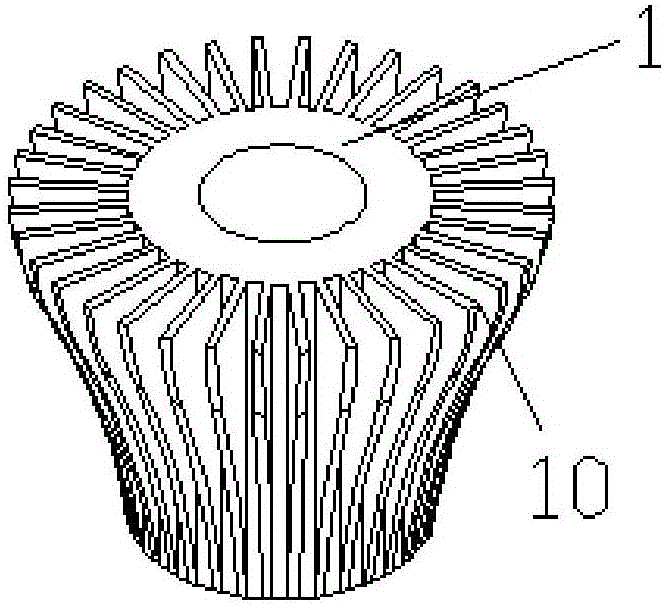

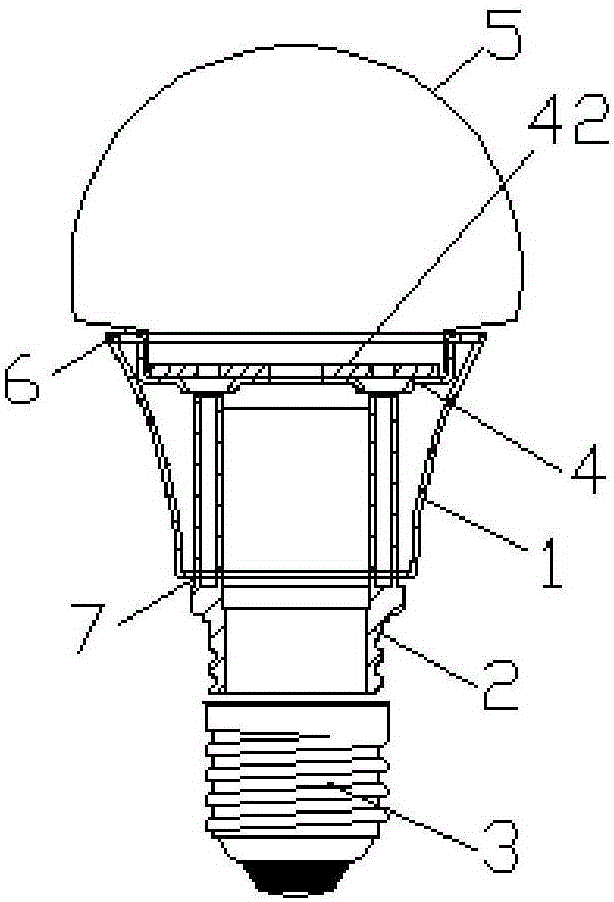

[0018] Such as Figure 3 to Figure 7 As shown, a heat dissipation structure of an LED lamp includes an aluminum lamp cup 1, the mouth of the lamp cup is connected to a glass bulb 5, a heat dissipation cover 4 is provided inside the mouth of the lamp cup, and a light-emitting electrical element 42 is installed on the heat dissipation cover. The bottom of the lamp cup is connected to the lamp holder 3 through the connecting piece 2. The heat dissipation cover 4 includes a cover body 40. A central hole 401 is opened in the center of the bottom of the cover body. Two side holes 402 are symmetrically opened on both sides of the center hole on the central axis of the bottom of the cover body. , the wire passes through the central hole 401 to connect with the light-emitting electrical element 42 and the lamp cap, and the mouth of the cover is provided with a circle of outward turning edge 41, and the outer turning edge 41 is uniformly opened with cooling holes 411 along the circumfere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com