Simple type differential pressure gas source collection and output method and device

An output method and differential pressure technology, which can solve the problems of gas leakage, air bag rupture, complicated operation, etc. by detecting the appearance of fluid at the leakage point, measuring devices, instruments, etc., to ensure safety, easy to carry, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

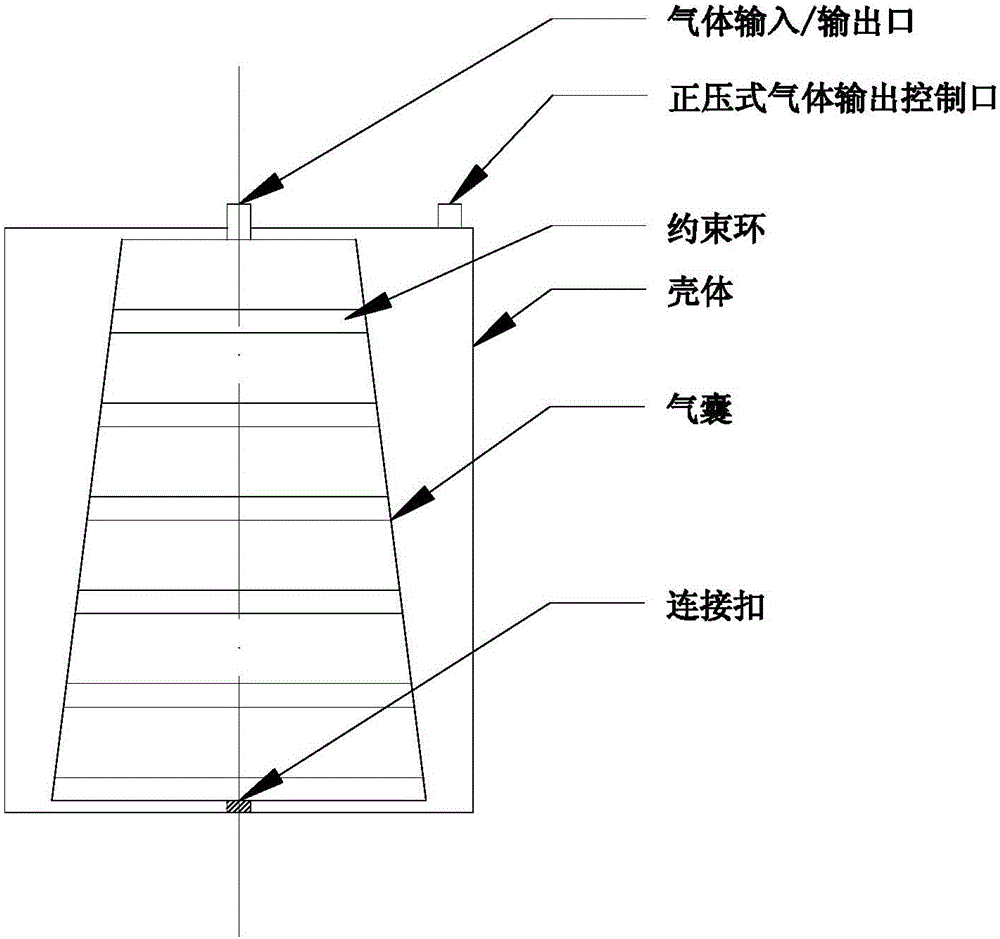

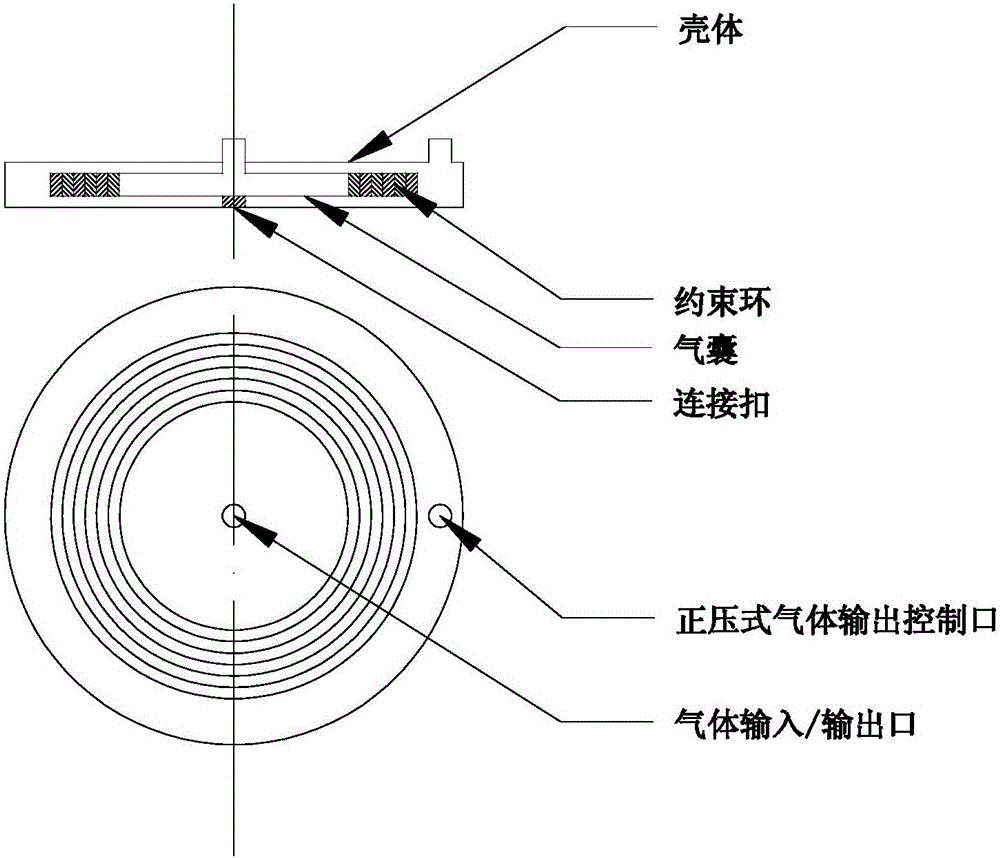

[0025] Gas collection method:

[0026] 1) The air bag is originally in a vacuum state, the air bag is stacked into a flat shape, the gas input / output port is opened to seal, and the sampling tube is connected;

[0027] 2) Pull the bottom of the sampling device, and under the action of pressure difference, the sampling gas is slowly injected into the air bag;

[0028] 3) Complete the gas collection, separate the sampling tube, and reseal the gas input / output port;

[0029] 4) If long-term storage or long-distance transportation is required, open the positive pressure gas output control port and inject a colored leak detection liquid, which is convenient for visual leak detection.

[0030] Gas output method:

[0031] 1) Open the positive pressure gas output control port and connect the fluid control pump;

[0032] 2) Open the gas input / output port and connect the gas flow rate controller;

[0033] 3) Disconnect the connecting buckle connecting the shell and the airbag;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com