Jump wire device and method

A flying lead and main insulation technology, applied in the field of electric power, can solve the problems of low efficiency and poor safety of high-voltage flying leads, and achieve the effects of high electrical and mechanical strength, high safety, and detachable components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

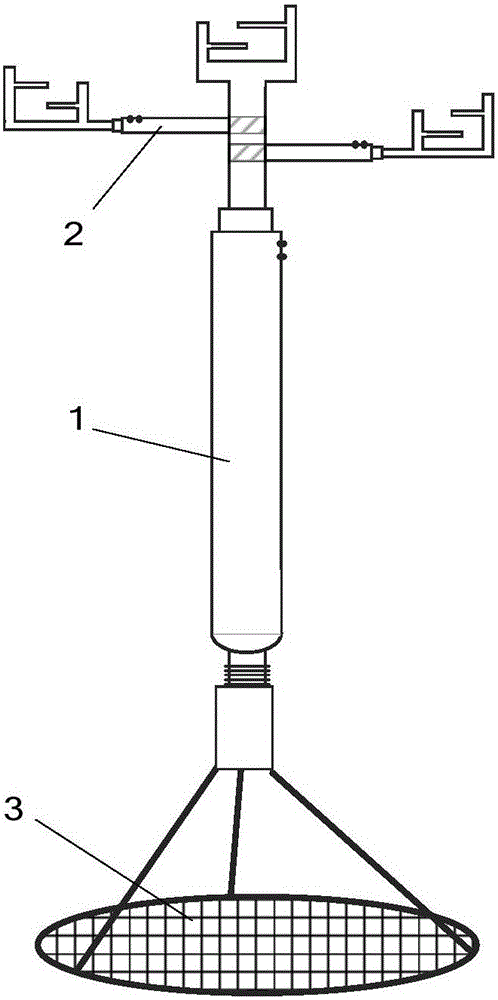

[0041] see figure 1 , is a schematic structural diagram of a flying lead device provided by an embodiment of the present invention, the flying lead device includes a main insulating rod 1 , a side insulating rod 2 and a fixed support 3 .

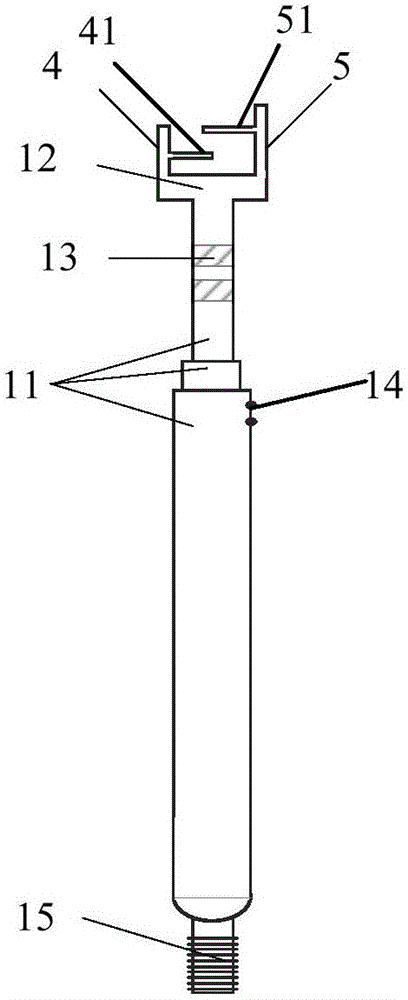

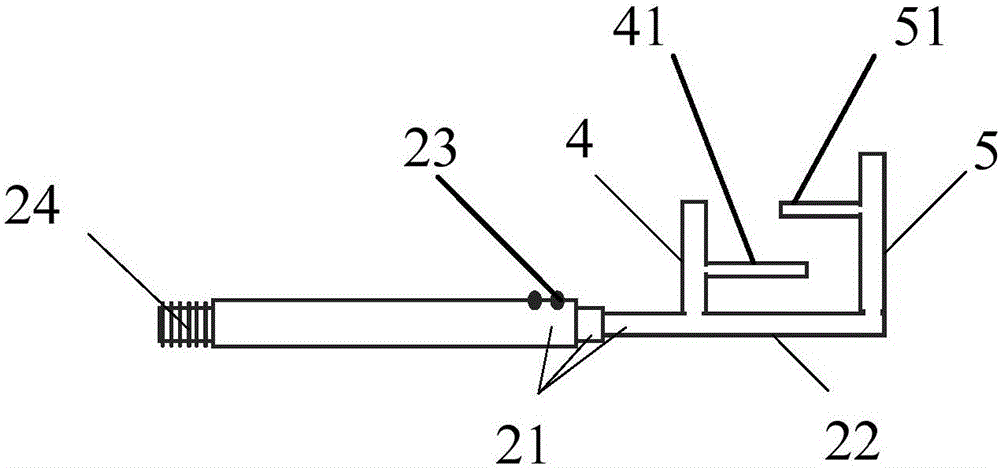

[0042] Among them, see figure 2 , is a schematic structural diagram of a main insulating rod provided by an embodiment of the present invention. The main insulating rod 1 includes a main insulating rod telescopic section 11 , a top fork 12 , a screw hole 13 , a main insulating buckle 14 and a main insulating bolt 15 . In the embodiment of the present invention, the main insulating rod 1 includes three main insulating rod telescopic joints 11, which are convenient for users to adjust the length. The above-mentioned expansion joint structure is a commonly used structure and will not be described in detail here. Of course, in actual implementation, the number of the main insulation rod expansion joints 11 can be any value, and the length and ...

Embodiment 2

[0050] see Figure 5 , is a structural schematic diagram of another fixed support provided by the embodiment of the present invention. The difference between the embodiment of the present invention and the first embodiment is that the fixed support in the implementation of the present invention is Figure 5 Pneumatic mounts shown. Specifically, the fixed support 3 includes an air pressure connection nut 34, an air pressure suction cup 35 and an air nozzle 36; wherein, the air pressure connection nut 34 matches the main insulating rod bolt 15, and the fixed support 3 is connected by the air pressure The screw mesh 34 is connected with the main insulating rod 1; the air pressure chuck 35 is an air pressure chuck including a suction cup cavity, and the air nozzle 36 is arranged on the top surface of the air pressure chuck 35 and is connected with the suction cup cavity. connected. For the similarities between the embodiment of the present invention and the first embodiment, ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com