Full-tensor gravity gradient measurement device and method

A technology of gravity gradient and measuring device, which is applied in the direction of measuring device, gravitational field measurement, geophysical measurement, etc., can solve problems such as impossible to achieve, and achieve the effect of avoiding contradictions and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

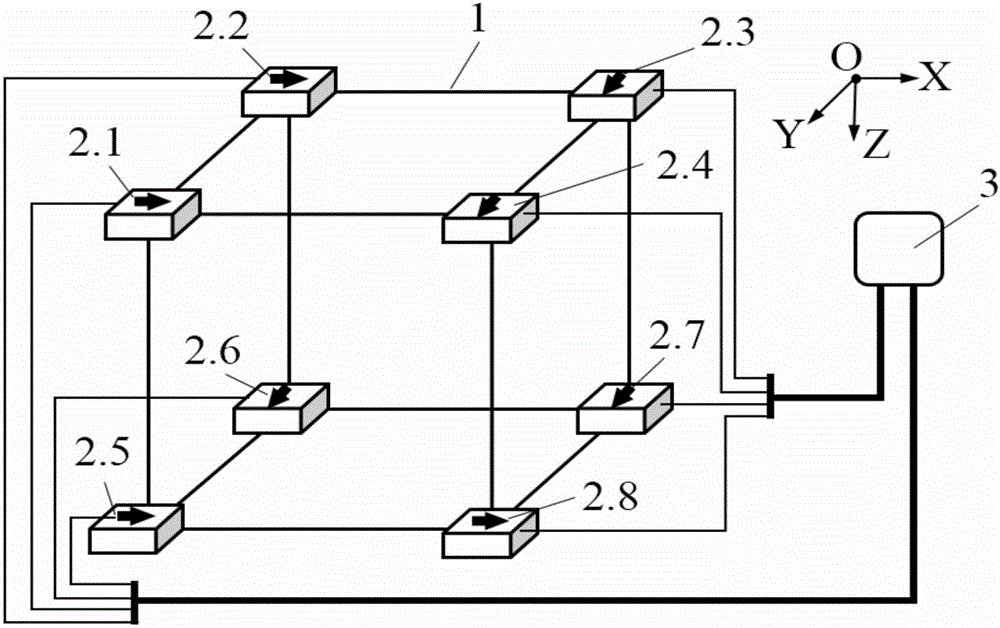

[0029] Such as figure 1The full tensor gravity gradient measuring device shown comprises a cube frame 1, eight accelerometers 2.1 to 2.8 and a computer 3, and the cube frame 1 is placed horizontally; the horizontal edges of the cube frame 1 are respectively along the north-south direction and the east-west direction, the vertical edge of the cube frame 1 is along the vertical direction; the eight accelerometers 2.1 to 2.8 are all single-axis accelerometers; the eight accelerometers 2.1 to 2.8 are respectively arranged on the cube At the corresponding eight corners of the frame 1; the sensitive axes of the eight accelerometers 2.1 to 2.8 are all in the horizontal plane, and the sensitive axes of four of the accelerometers 2.1, 2.2, 2.5 and 2.8 are along the north-south direction while the other four The sensitive axes of the accelerometers 2.3, 2.4, 2.6 and 2.7 are along the west-east direction; among the four accelerometers 2.1, 2.2, 2.3 and 2.4 on the same horizontal plane of...

Embodiment 2

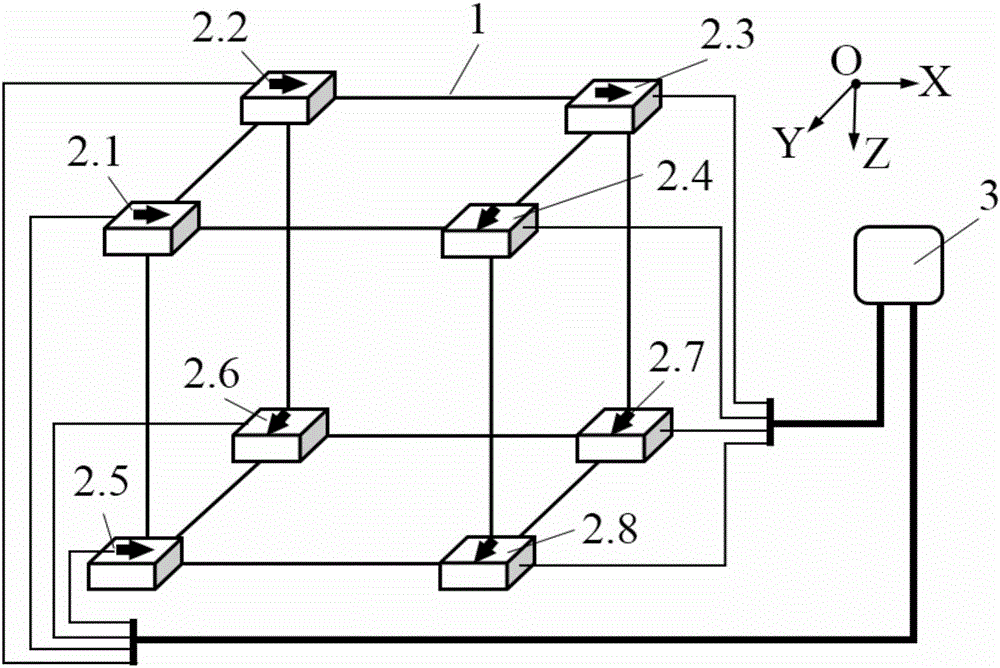

[0049] Such as figure 2 The full tensor gravity gradient measuring device shown comprises a cube frame 1, eight accelerometers 2.1 to 2.8 and a computer 3, and the cube frame 1 is placed horizontally; the horizontal edges of the cube frame 1 are respectively along the north-south direction and the east-west direction, the vertical edge of the cube frame 1 is along the vertical direction; the eight accelerometers 2.1 to 2.8 are all single-axis accelerometers; the eight accelerometers 2.1 to 2.8 are respectively arranged on the cube At the corresponding eight corners of the frame 1; the sensitive axes of the eight accelerometers 2.1 to 2.8 are all in the horizontal plane, and the sensitive axes of four of the accelerometers 2.1, 2.2, 2.3 and 2.5 are along the north-south direction while the other four The sensitive axes of the accelerometers 2.4, 2.6, 2.7 and 2.8 are in the west-east direction; of the four accelerometers 2.1, 2.2, 2.3 and 2.4 on the same horizontal plane of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com