Real-time energy efficiency optimization method for combustion gas turbine

A gas turbine and analysis method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of closed gas turbine technology, large unit output fluctuations, low transparency, etc., to achieve energy efficiency and closed-loop adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

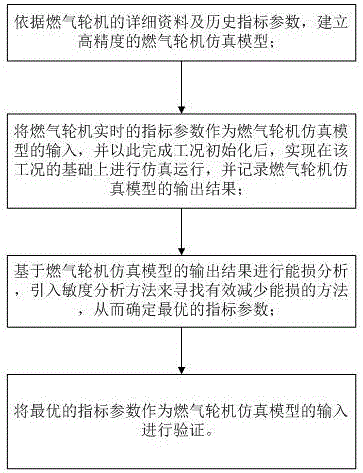

[0020] like figure 1 As shown, the gas turbine real-time energy efficiency optimization method provided by the present invention includes the following steps:

[0021] S1. Establish a high-precision gas turbine simulation model based on the detailed data and historical index parameters of the gas turbine;

[0022] S2. Use the real-time index parameters of the gas turbine as the input of the gas turbine simulation model, and after completing the initialization of the working condition, realize the simulation operation on the basis of the working condition, and record the output results of the gas turbine simulation model;

[0023] S3. Carry out energy loss analysis based on the output results of the gas turbine simulation model, and introduce a sensitivity analysis method to find an effective way to reduce energy loss, so as to determine the optimal index parameters;

[0024] S4. Verifying the optimal index parameters as the input of the gas turbine simulation model.

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com