Ice cutting system for high-voltage line

A high-voltage line, ice layer technology, applied in the installation of electrical components, cables, overhead installation, etc., can solve problems such as inability to spread out, the influence of high-voltage line power supply, and the inability to adapt to complex and changeable external environments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

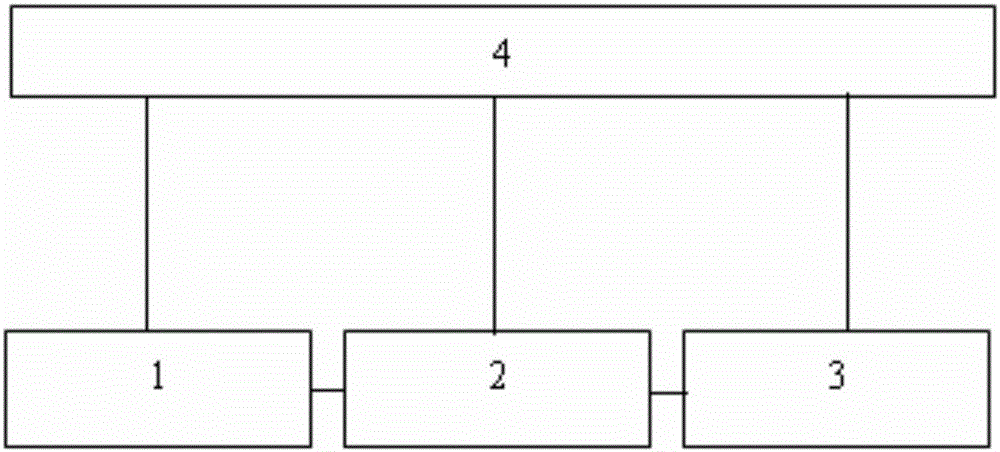

[0017] The implementation of the fiber grating detection based high voltage line ice cutting system of the present invention will be described in detail below with reference to the accompanying drawings.

[0018] At present, manual methods or high-voltage line pretreatment methods are generally used to deal with the icing of high-voltage lines in the transmission grid. However, the former consumes a lot of manpower and material resources, and the deicing efficiency is not high, and the risk of deicing is high. The cost is high, and the key is that the ability to overcome icing is also limited. At present, there are still some technical solutions for remote control of online deicing by robots. However, due to the unreasonable structure of existing robots, they cannot adapt to the complex high-voltage line environment, and still require a lot of manual intervention, and the overall cost is also high. More importantly, there is a lack of effective automatic detection equipment fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com