An automatic cleaning device for factory floors

A technology for automatic cleaning and floor cleaning, which is applied to cleaning equipment, cleaning carpets, cleaning floors, etc. It can solve the problems of human injury, high labor intensity, low efficiency, etc., and achieve the effect of flexible movement ability, improving work efficiency and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

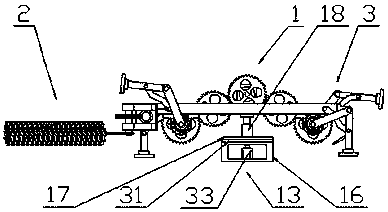

[0026] refer to Figure 1-Figure 6 , the present invention provides an automatic cleaning equipment for factory floor, including drive system 1, cleaning system 2 and motion system 3,

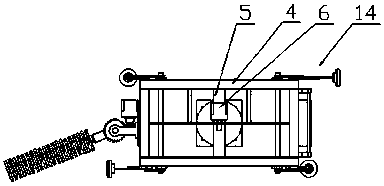

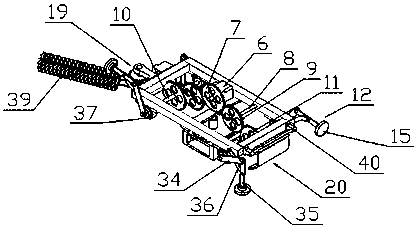

[0027] The drive system 1 includes a frame 4, the frame 4 is a square structure, a horizontal plate 5 is arranged between the longitudinal beams on both sides of the frame 4, the horizontal plate 5 is arranged at the center of the longitudinal beams, a motor A6 is arranged on the horizontal plate 5, and the output of the motor A6 A gear A7 is arranged on the shaft, an arbor 8 is arranged symmetrically with respect to the horizontal plate 5 on the longitudinal beam on one side of the frame 4, a gear B9 is arranged on the arbor 8, and a rotating shaft A10 is arranged symmetrically on the front and rear ends of the frame 4, and the rotating shaft A10 is arranged on There is gear C11, gear A7 meshes with gear B9, and gear B9 meshes with gear C11;

[0028] The motion system 3 includes a walking par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com