Disc type forge piece forging mold and forging method

A technology for forgings and discs, which is applied in the field of forging methods, can solve the problems of low production efficiency, waste of raw materials, time-consuming and labor-intensive problems, and achieve the effects of prolonging service life, avoiding equipment investment and energy consumption, and reducing forming force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

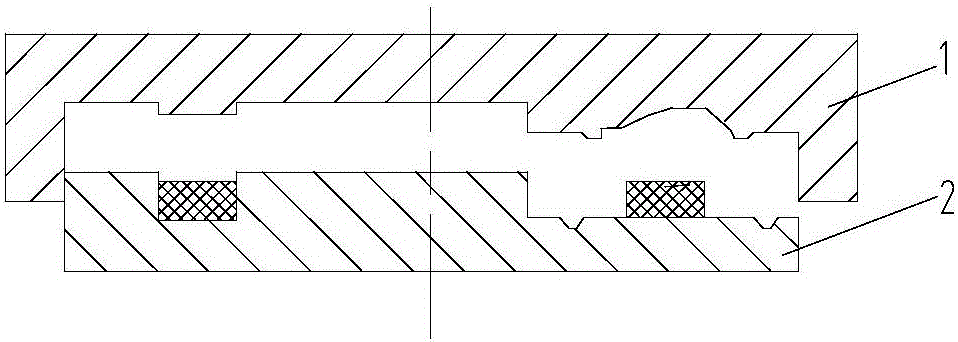

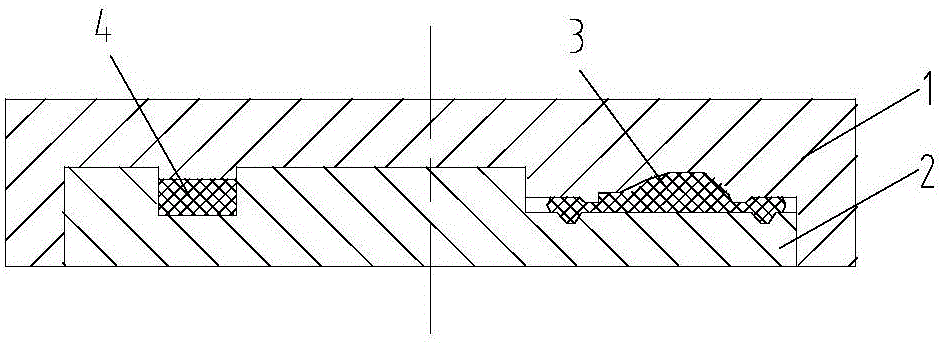

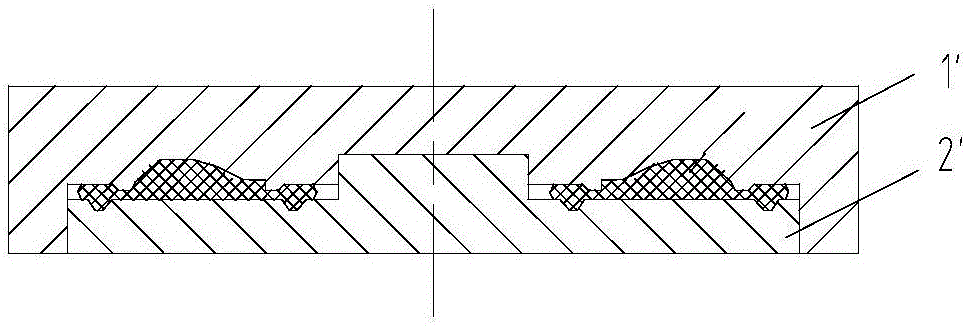

[0031] The disc forging die of the present embodiment is as Figure 1 to Figure 3 As shown, two pairs of molds are included, one of which is as figure 1 , 2 As shown, it consists of a front upper die 1 and a front lower die 2. After the front upper die 1 and the front lower die 2 are closed, the inner cavity is divided into two halves, and the forming part 3 and the The receiving part 4 conforms to the shape of the forging blank. Another pair of molds such as image 3 As shown, it is the finished upper mold 1' and the finished lower mold 2' whose inner cavity matches the shape of the finished forging after mold closing.

[0032] In order to suppress the misalignment force of the mold in the partition forming forging process, and avoid excessive misalignment leading to the scrapping of forgings and the tendency of mold cracking, the mold of this embodiment is provided with a self-locking structure, that is, the front upper mold 1 and the finished upper mold 1' The outer cir...

Embodiment 2

[0041] The disc forging die of the present embodiment is as Figure 8 to Figure 11 As shown, two pairs of dies are also included, one of which is as Figure 8 , 9 As shown, it consists of a front upper die 1 and a front lower die 2. After the front upper die 1 and the front lower die 2 are closed, the inner cavity is divided into two halves, and the forming part 3 and the The receiving part 4 is formed by receiving the shape of the forging blank, and the receiving part includes a detachable mold core installation position located at the front upper die 1 and a detachable core positioning recess 4-1 located at the center of the front lower die 2 . In this way, if Figure 10 , 11 As shown, the finished upper mold and the finished lower mold whose inner cavity matches the shape of the finished forging after mold closing are essentially composed of the front upper mold 1 and the front lower mold 2 embedded with the detachable core 1-1. The movable mold core 1-1 has a forming p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com