Novel hole protecting device and use method thereof

A protective device and a new type of technology, applied in auxiliary devices, grinding/polishing safety devices, auxiliary welding equipment, etc., can solve problems such as difficult cleaning of debris, failure of protection, cumbersome working process, etc., to eliminate safety and quality accidents, prevent The effect of foreign matter entering the cavity and simplifying the workflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

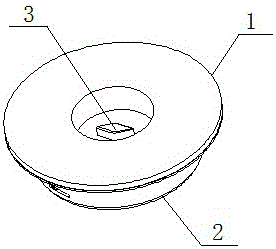

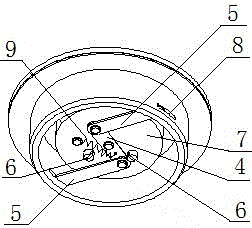

[0028] The novel hole protection device of the present invention includes a base, a locking mechanism and a rotating handle 3 .

[0029] base, such as figure 1 As shown, it is made of nylon, and is divided into two parts: an upper blocking cover 1 and a lower blocking body 2, and the blocking body 2 is at the center of the lower part of the blocking cover 1. The plugging cover 1 is a disc structure with a diameter larger than the aperture of the plugged hole, and the shape of the plugging body 2 is a cylinder matching the plugged hole, so that the base can be well matched with the corbel cavity. The center of the upper surface of the blocking cover 1 is provided with a groove, and the rotating handle 3 is installed in the groove. The lower edge of the plugging cover 1 is provided with a layer of gasket, thereby increasing the sealing performance between the plugging cover 1 and the plugged hole, and preventing finer foreign matter from entering the plugged hole.

[0030] Suc...

Embodiment 2

[0035] Such as Figure 4 As shown, the difference from the first embodiment is that the straight twisted piece 4 is replaced by a bent twisted piece 11 . The bending and torsion piece 11 is concave in the middle, and the lower concave surface is closely attached to the support platform 7. The height of the two ends of the bending and torsion piece 11 is adapted to the height of the blocking body 2 and the position of the lock 8, which reduces the movable gap of the central connecting rod. Shaking in use of the device is avoided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com