Electric mould clamping mechanism of injection moulding machine

A technology of injection molding machine and electric lock, which is applied in the field of injection molding machine manufacturing, can solve the problems of complex and huge pulley system device structure, large error of ball screw straightness accuracy, and short service life of belt, so as to reduce technical difficulties and manufacture The effect of cost, fast mode-locking response, and short transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

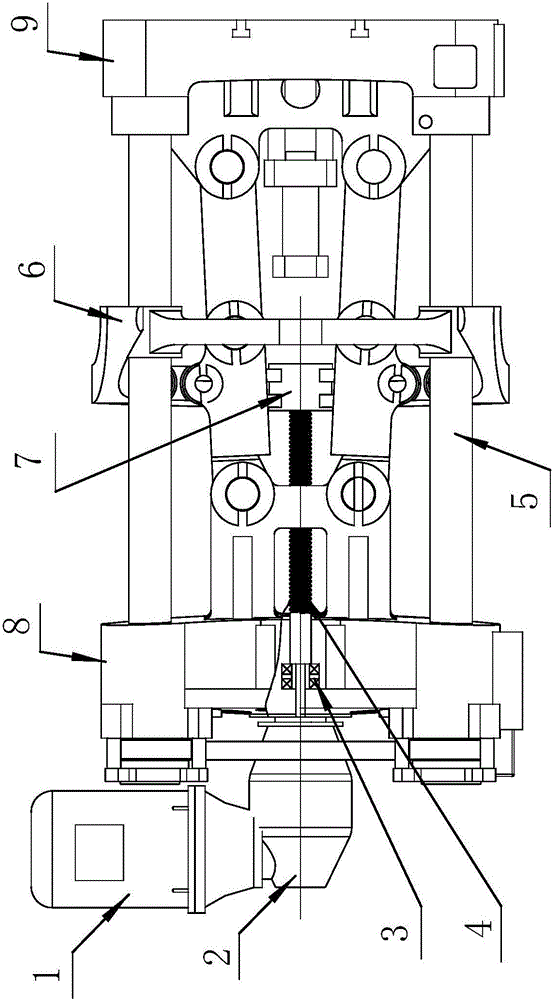

[0011] like figure 1 As shown, the electric clamping mechanism of the injection molding machine of the present invention includes a servo motor, a ball screw 4, a bearing seat 3, a crosshead 6, a screw seat 7, a tail plate 8, and a reducer. In this embodiment, the reducer The motor is a planetary reducer 2, and of course the reducer can also be a box-type reducer, etc., and the servo motor is an AC servo motor 1. The planetary reducer 2 is installed on the outer end face of the tail plate 8, the AC servo motor 1 is installed on the reducer, the front end of the AC servo motor 1 extends into the rear end of the planetary reducer 2 and is directly rigidly connected with the planetary reducer 2, this way Only one transmission part, that is, the planetary speed reducer 2 is used, and its structure is simpler compared with the existing pulley transmission technology. The AC servo motor 1 is fixedly connected to the planetary reducer 2, so that the transmission distance of the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com