Novel low-building type rollover-prevention device of under-hung crane

A suspension crane, anti-tipping technology, applied in the direction of safety devices, transportation and packaging, load hanging components, etc., can solve the problems of tipping, wheel negative wheel pressure, crane metal structure damage, etc., to achieve the elimination of load pressure, Effect of reduced contact gap, sensitive and fast measurement response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

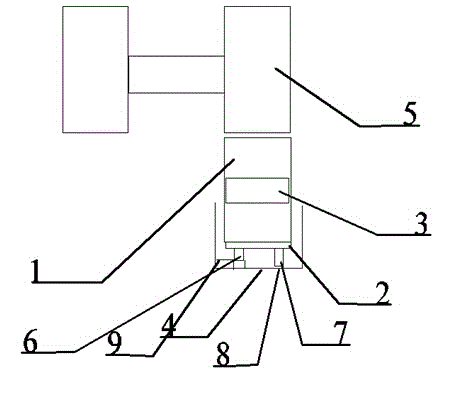

[0019] A novel anti-tipping device for low-building suspension cranes, characterized in that it includes: anti-rolling wheel 1, bearing 2, anti-rolling wheel shaft 3, anti-rolling wheel base 4, driving wheel 5; anti-rolling wheel base 4 is fixed on the end by bolts On the beam channel steel, it is used to support the anti-rolling wheel group. The gear on the anti-rolling wheel base 4 meshes with the gear on the driving wheel 5. When in use: the anti-rolling device is arranged on the end beam that will generate negative wheel pressure. When the crane When the wheel generates negative wheel pressure, the anti-roll wheel is in contact with the lower plane of the track, and the active wheel drives the anti-roll wheel to realize the running of the cart through the rotation of the anti-roll wheel.

Embodiment 2

[0021] Example 2 as figure 1 As shown, it is improved on the basis of Embodiment 1, and its anti-rolling wheel 1 adopts a flat tread wheel, and the clearance between the wheel tread and the lower plane of the track is 2 to 3 mm. Therefore, the use of flat tread wheels reduces the contact gap, and the fixed gap is within the specified range, which is helpful for the effective control of the anti-rollover device. When the distance between the anti-rolling wheel and the track is too large, the crane is prone to rollover. On the contrary, when the wheel is too tightly connected to the track, the working pressure of the crane will be too large and the efficiency will become low.

Embodiment 3

[0023] Example 3 as figure 1 As shown, it is improved on the basis of Embodiment 1. Its described anti-roller base 4 is provided with a level detector 6 and an independent oil cylinder 7, and is remotely controlled by a controller switch. Equipped with automatic detection equipment, when a tipping phenomenon is detected, the level detector controls the switch to make the independent oil cylinder act to form compensation. At the same time, the independent oil cylinder provides power, which will not affect the normal operation of the crane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com