Non-woven fabric lapping machine air supply mechanism

A technology of air supply mechanism and web laying machine, which is applied in the directions of non-woven fabrics, textiles and paper making, etc., can solve the problems of affecting product quality, low strength, non-uniform web, etc., so as to improve the quality of the final product, improve the uniformity and Strength, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

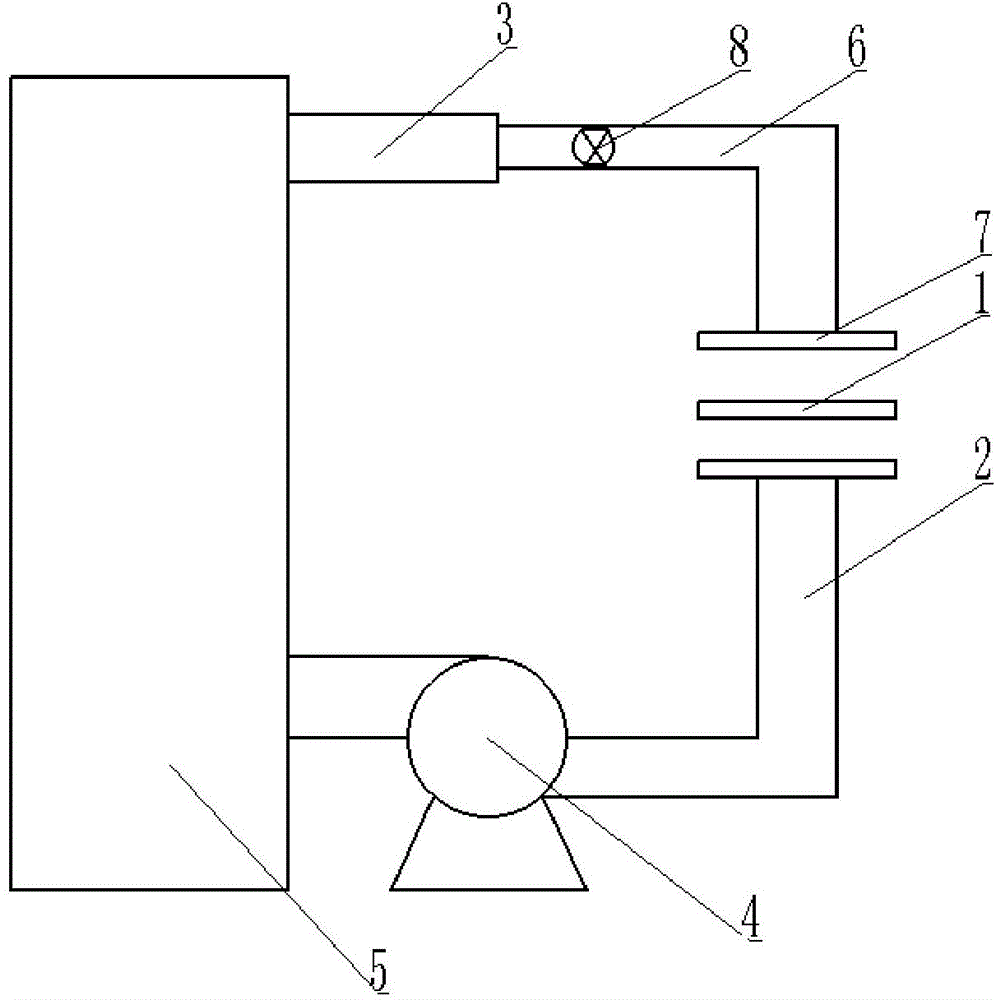

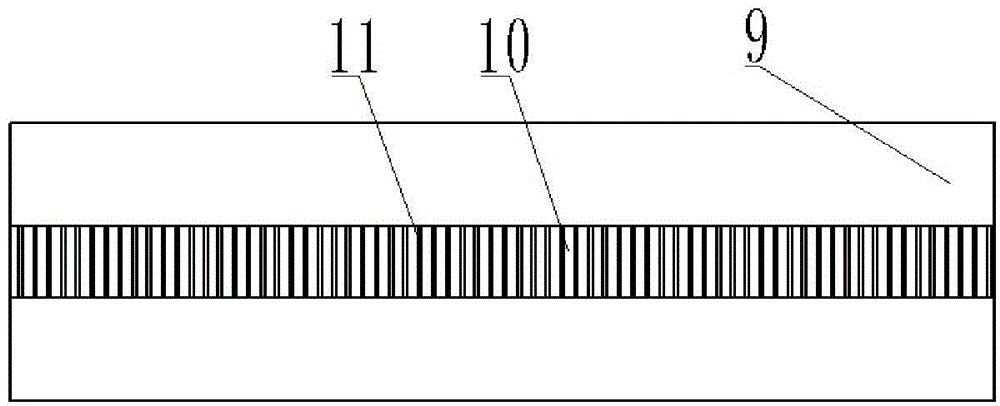

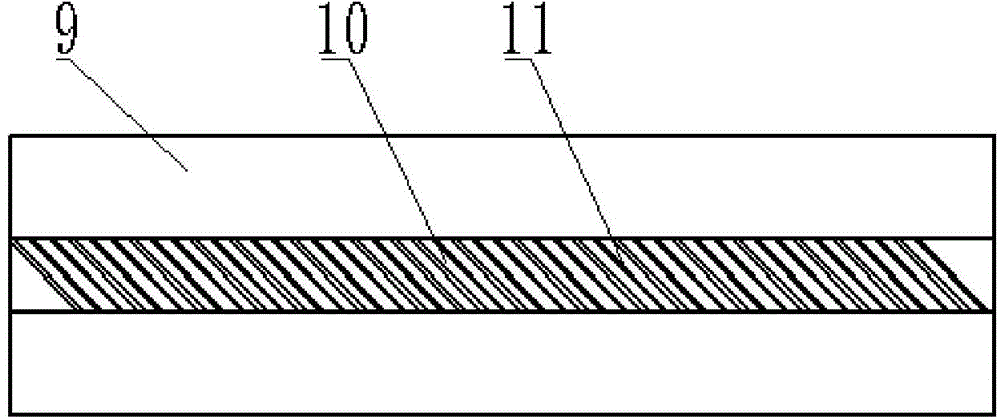

[0015] Such as figure 1 , 2 Shown in and 3, a kind of air supply mechanism of non-woven web lapper comprises net lapper net curtain 1, is provided with suction passage 2 below the net curtain 1 of net lamination machine, is provided with air inlet passage 3 above, and described The suction channel 2 is connected to the suction fan 4, and the suction fan 4 is connected to the air-conditioning treatment chamber 5, and the air-conditioning treatment chamber 5 is connected to the air inlet pipe 3. The air outlets of the branch air inlet ducts 6 are all facing the net curtain 1 of the net lapper, and the air outlets are equipped with an even air plate 7, and each of the branch air inlet ducts 6 is provided with a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com