A kind of industrial grade calcium hydroxide production equipment and its production process

A calcium hydroxide and production equipment technology, applied in the field of industrial calcium hydroxide production equipment and its production process, can solve the problems of large investment in fixed assets, high cost of carbide slag, high unit power consumption, etc., to improve production efficiency and speed The effect of speeding up and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

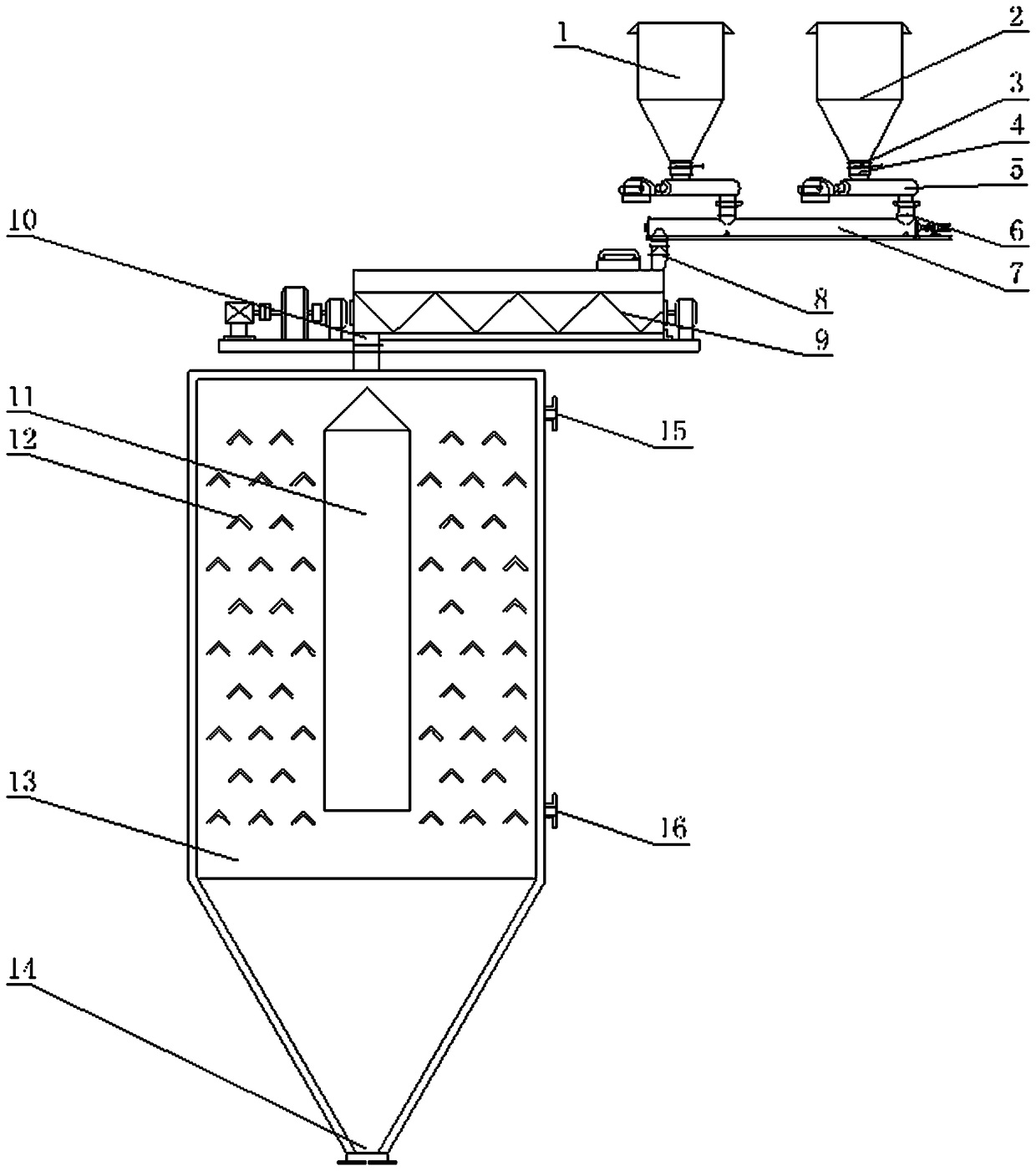

[0028] The industrial grade calcium hydroxide production equipment of the present embodiment, such as figure 1As shown, including carbide slag bin 1, lime bin 2, feeding screw reamer 7, double shaft mixer 9 and digestion bin 13, carbide slag bin 1 and lime bin 2 are respectively communicated with feeding screw reamer 7, carbide slag bin 1 and the lime silo 2 and the feeding screw reamer 7 are respectively provided with a spiral electronic weighing scale 5, and the calcium carbide slag silo 1 and the lime silo 2 are respectively connected with the spiral electronic weighing scale 5 through the first soft joint 4, and the spiral electronic weighing scale is connected. 5 communicates with the feeding helical reamer 7 through the second soft joint 6 . A one-way screw valve 3 is respectively installed between the carbide slag bin 1 and the lime bin 2 and the first soft joint 4 . The outlet of the feeding screw reamer 7 is communicated with the feed port 8 of the twin shaft mixer 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com