A prestressed laminated slab member

A laminated board and prestressing technology, applied in building components, floor slabs, building structures, etc., can solve the problems of lowering floor height clearance, complex cast-in-place process, and large amount of steel bars, so as to reduce self-weight, firm overall structure, and reduce cross-section. The effect of a large moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described with reference to the accompanying drawings.

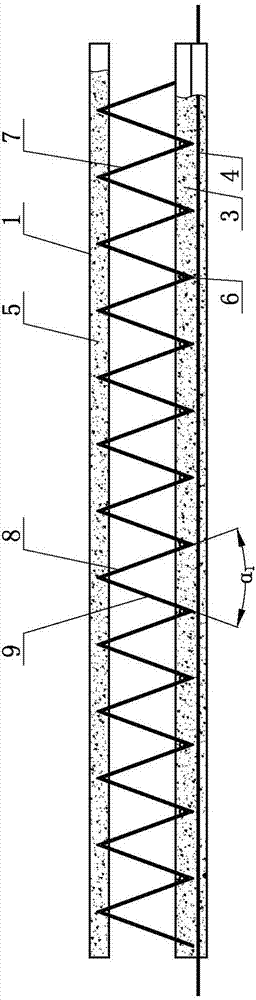

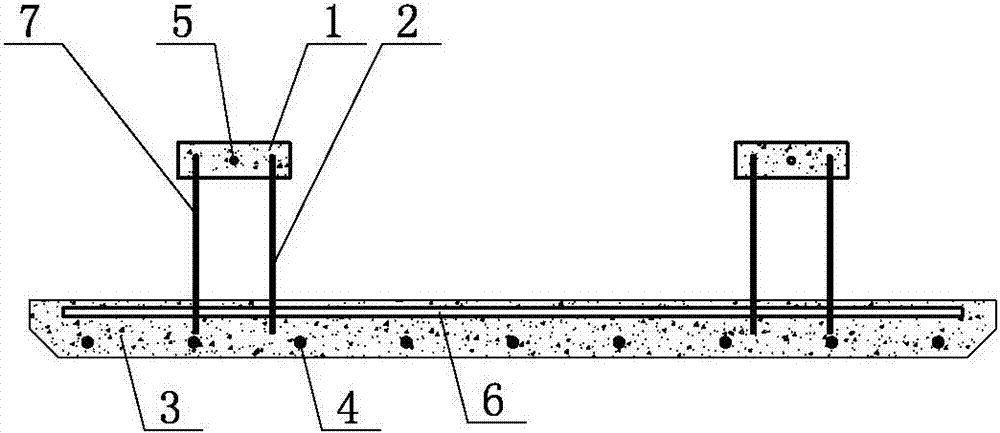

[0008] 3 in the figure is the bottom plate. At least one row of steel bar trusses is arranged on the bottom plate 3. The steel bar trusses are composed of concrete ribs 1, first steel bars 7 and second steel bars 2. One end of the first steel bar 7 and one end of the second steel bar 2 are connected to the concrete ribs respectively. The rib 1 is connected, the other end of the first steel bar 7 and the other end of the second steel bar 2 are respectively connected with the bottom plate 3, the first steel bar 7 and the second steel bar 2 are parallel in the length direction, and the first steel bar 7 is bent into several lengths along the length direction. A first oblique aid 8 and several second oblique aids 9, a first included angle α is set between the first oblique aid 8 and the second oblique rib 9 1 , the first included angle α 1 is an acute angle, the second steel bar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com