Flow rate pairing valve and electrohydraulic actuating mechanism adopting same

A technology of electro-hydraulic actuator and flow matching valve, applied in mechanical equipment, servo meter circuit, fluid pressure actuating device, etc., can solve the problems of unsuitability for high-frequency action, insufficient reliability, large volume, etc., and achieve a simple structure. , without maintenance, the effect of improving the circulation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

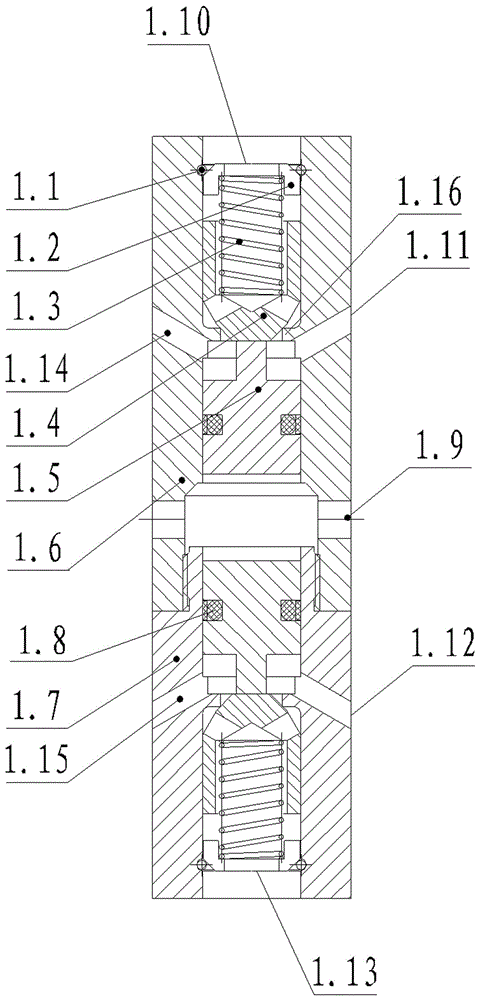

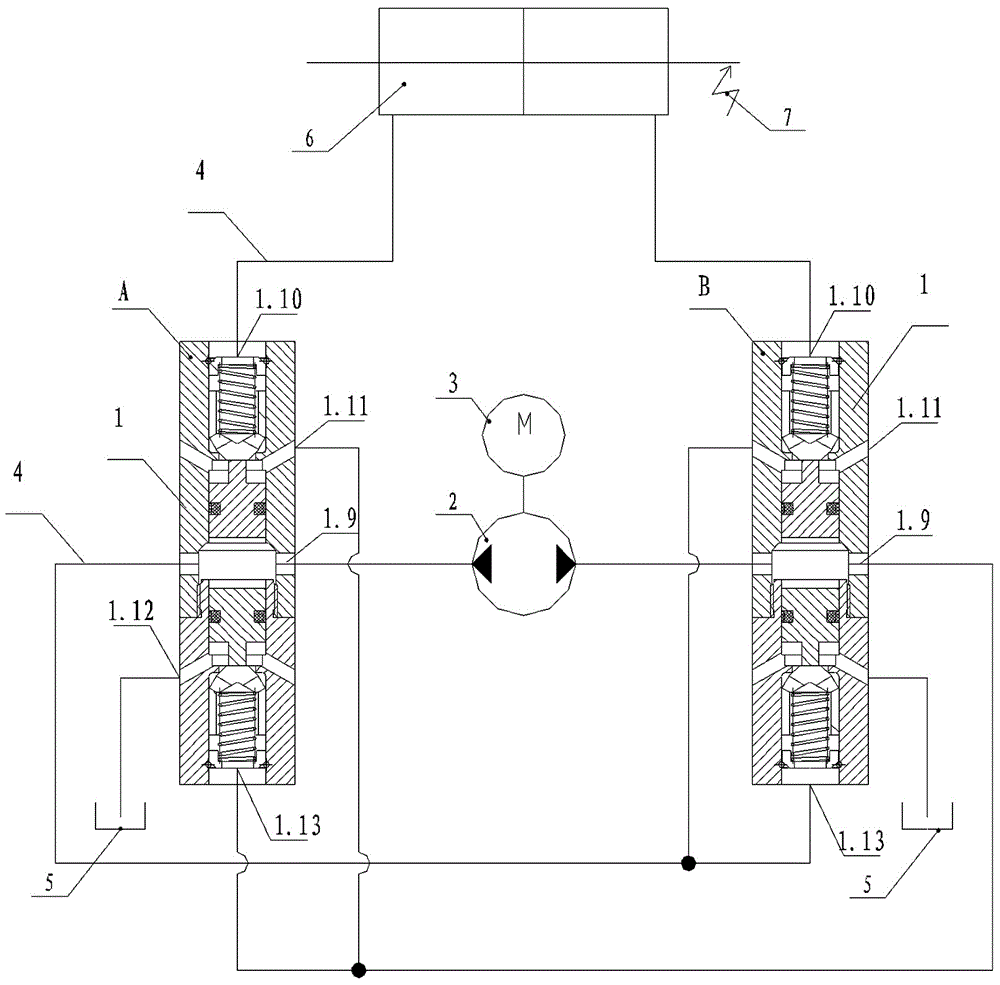

[0032] see figure 1As shown, a flow matching valve includes a valve body, the upper and lower parts of the valve body are provided with a first valve cavity for installing a piston and a second valve cavity for installing a one-way valve core, the first The annular boss 1.16 used to support the one-way valve core between the valve chamber and the second valve chamber, the first valve chamber communicates with the second valve chamber, and the two second valve chambers are respectively located at both ends of the valve body. Each of the second valve chambers is provided with a one-way valve core. The one-way valve core adopts a conical one-way valve core 1.4. The conical one-way valve core 1.4 is composed of a conical cylinder and a cylinder. The spring installation hole, the oil hole connected to the spring installation hole is provided on the tapered column, and the seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com