Three-way valve

A three-way valve and valve body technology, applied in multi-way valves, valve devices, engine components, etc., can solve the problem of high price and achieve the effects of large bearing capacity, cost reduction and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present technology will be further described below in combination with the drawings and specific embodiments.

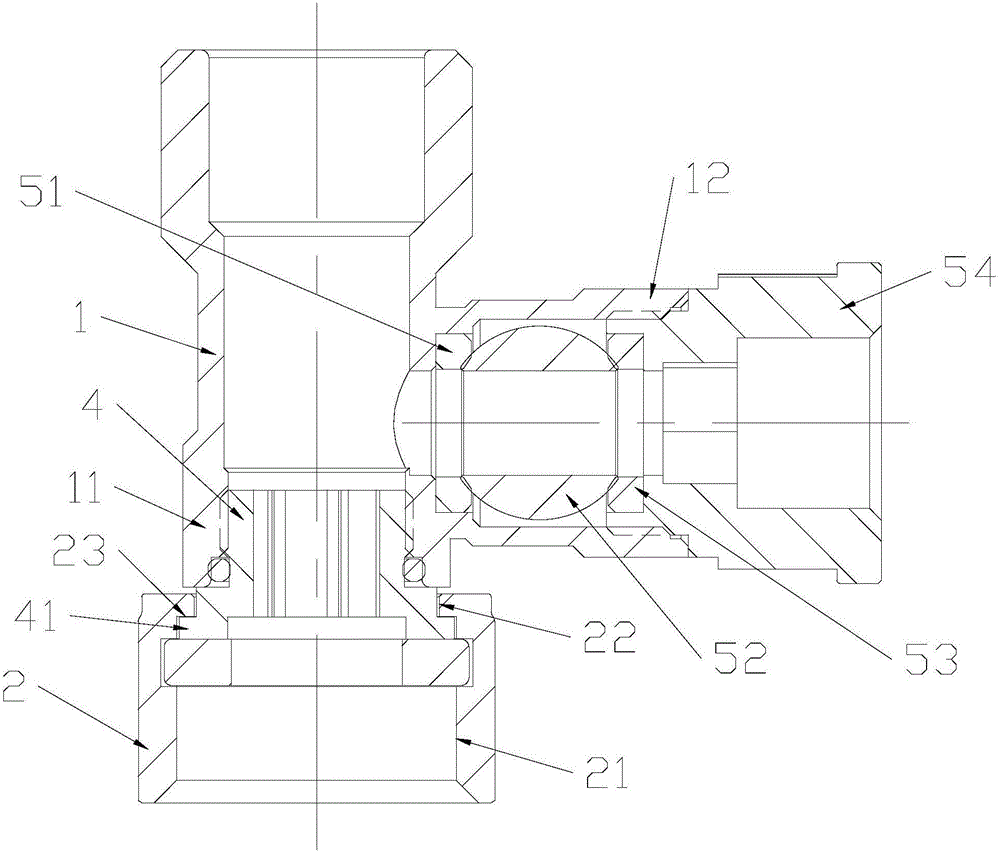

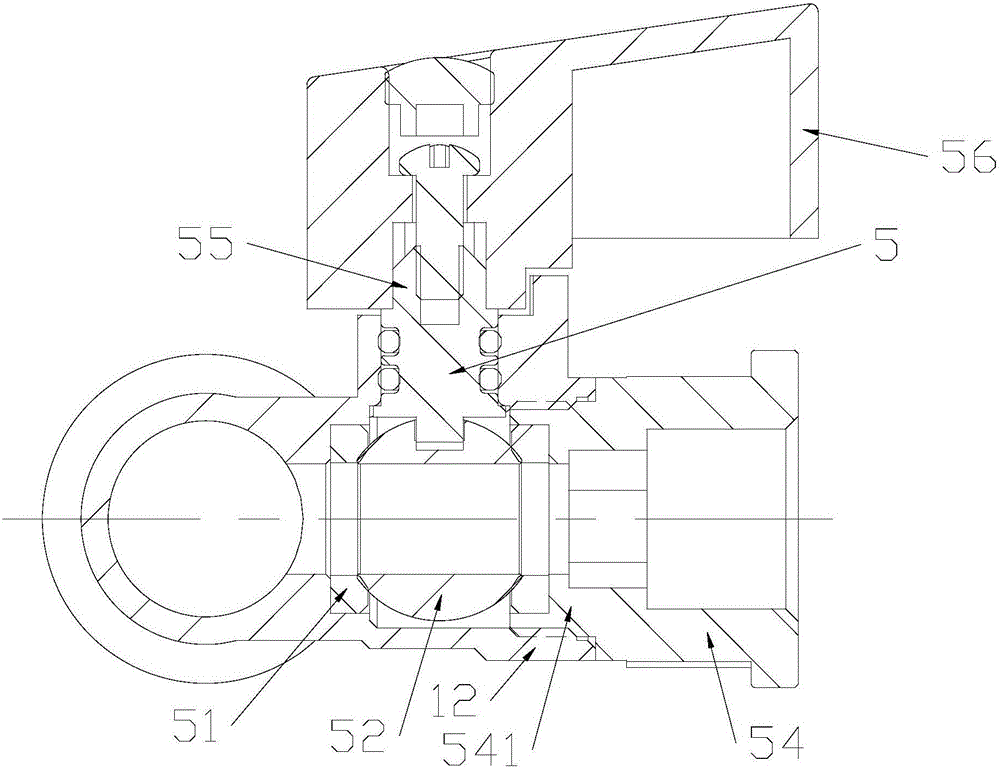

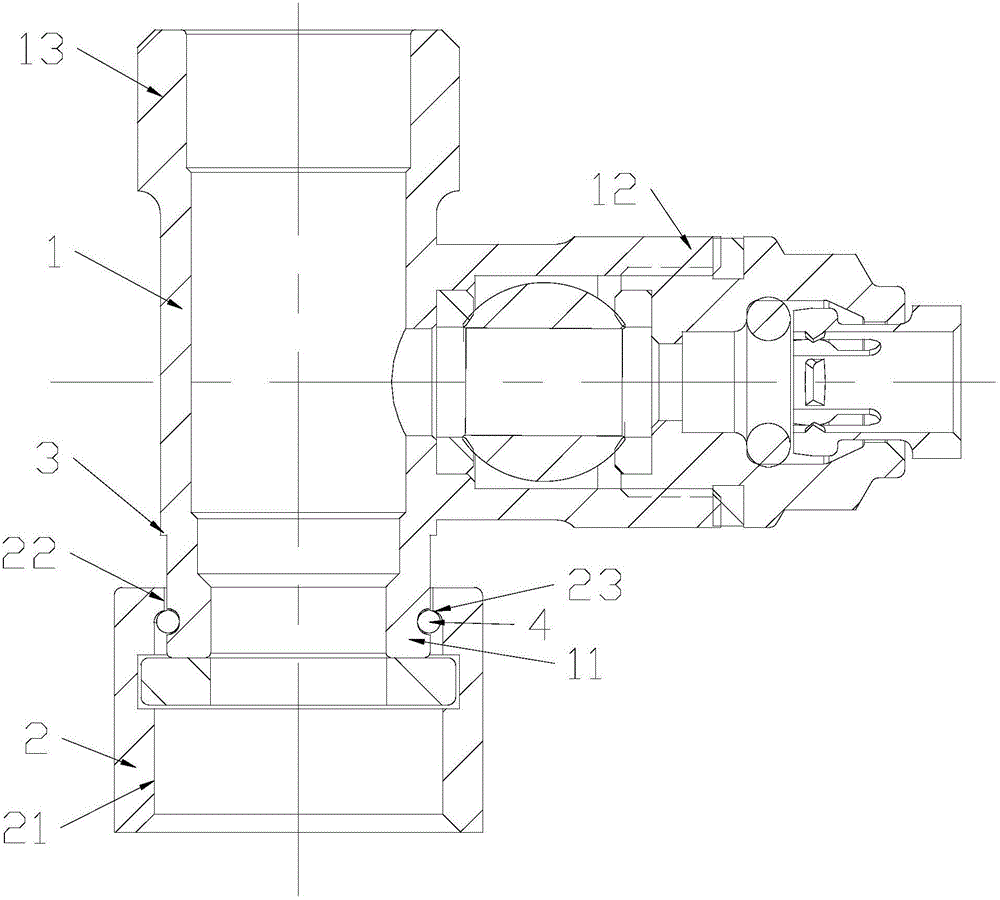

[0025] see image 3 , 4 The three-way valve shown has a valve body 1, and the valve body has three communicating ports, one of which is the cap port 11 connected to the movable nut 2, one port is the valve port 12 for installing the ball valve 5, and one port is the outer peripheral port. An externally threaded port 13 with an external thread.

[0026] The movable nut includes an inner hole 21 at the front and a necking 22 at the rear, the diameter of the inner hole is c, and the diameter of the necking is e; a step surface 23 is formed between the necking and the inner hole; between the step surface and the wall of the inner hole Transition with rounded corners.

[0027]The cross section of the circlip 4 is a circle with a diameter R, obviously, the width of the circlip 4 in the radial direction is f=the thickness in the axial direction is x=diameter R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com