Fixing device for secondary reflection mirror of linear Fresnel heat absorber

A technology of linear Fresnel and secondary reflectors, applied in heating devices, solar thermal devices, solar collectors, etc., can solve the problem of affecting the surface shape accuracy of secondary reflectors, reducing the Mirror damage and other problems, to achieve the effect of reducing adverse effects, improving stability and reliability, and good light-gathering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

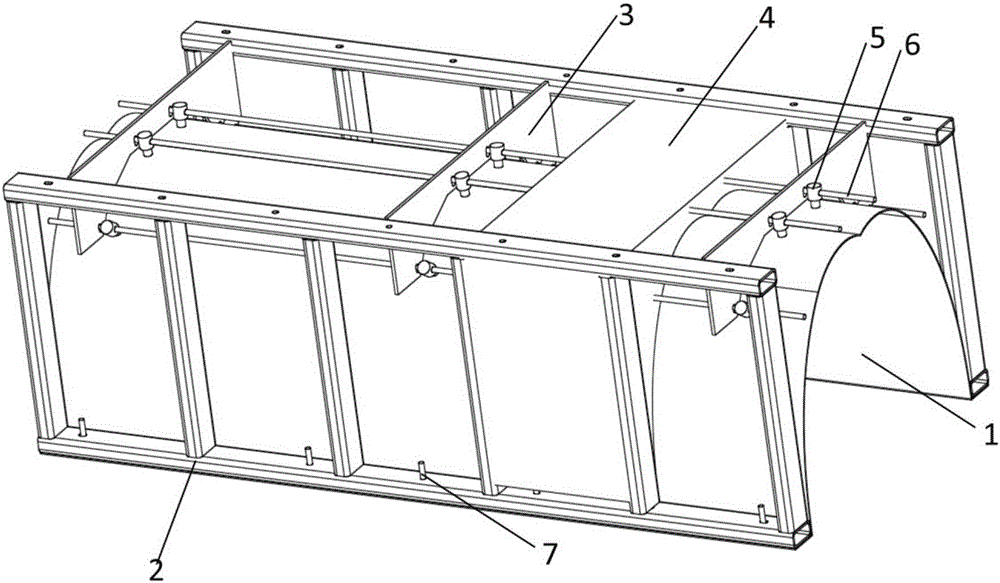

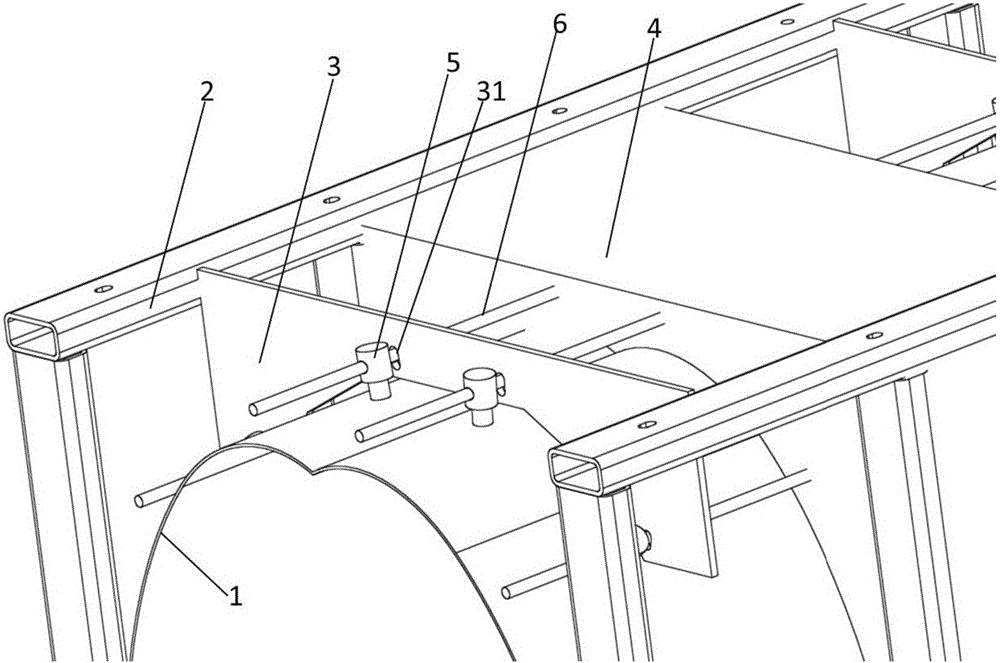

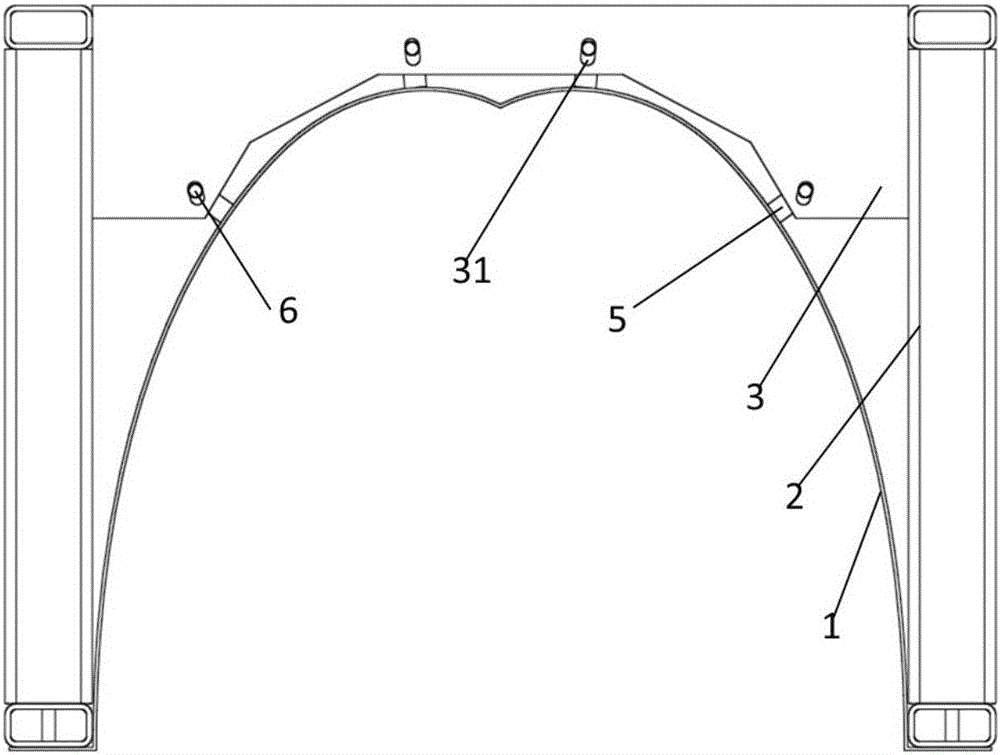

[0031] see Figure 1 to Figure 5 , a linear Fresnel heat absorber secondary reflector fixing device provided by the present invention includes a support frame 2, a mounting hole 21 is opened on the bottom beam of the support frame 2, and the secondary reflector 1 passes through the mounting hole 21 The connecting piece 7 is connected with the bottom beam; the top beams of the support frame 2 are provided with a plurality of vertical plates 3, the back of the secondary reflector 1 is provided with a fixed buckle 5, and the vertical rod 6 is connected in series with the pass on the fixed buckle 5. The slot 31 provided on the hole and the vertical plate 3; the longitudinal bar 6 can move in the slot 31 perpendicular to the length direction, and the fixing buckle 5 can slide on the longitudinal b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com