Self-adaptive transposition type thermal insulation concrete block and preparation method thereof

A thermal insulation concrete, self-adaptive technology, applied in the direction of thermal insulation, climate change adaptation, application, etc., can solve the problems of short service life, high cost, insufficient thermal insulation capacity, etc., and achieve the effect of avoiding excessive weight gain and effective thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

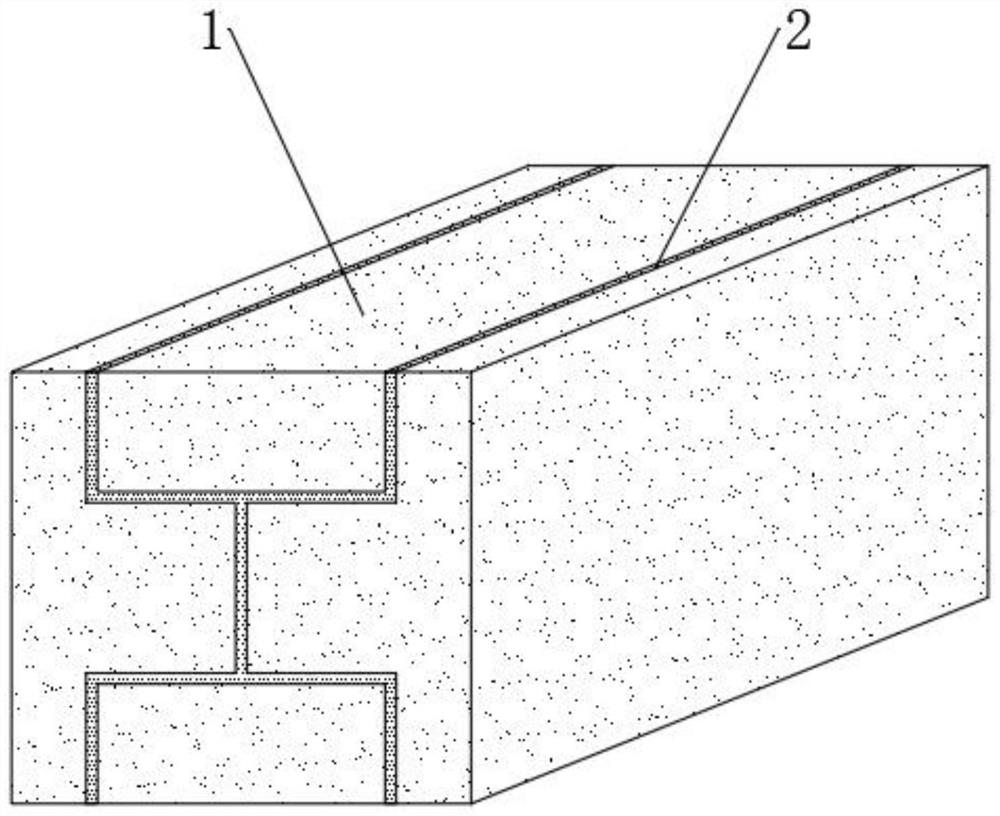

[0046] see Figure 1-2 , an adaptive transposition type thermal insulation concrete block, comprising a block body 1 and an inorganic thermal insulation material 2 embedded in the block body 1, characterized in that: the block body 1 uses the following raw materials in parts by weight: cement 60 parts, 10 parts of mineral powder, 15 parts of fly ash, 40 parts of vitrified microspheres, 1 part of polyacrylamide, 1 part of polyvinyl alcohol, 0.5 parts of cellulose, 0.5 parts of PP fiber, 1 part of water reducer, aluminum 2 parts powder, 0.1 part accelerator, 0.1 part triethanolamine, 0.1 part sodium sulfate, 15 parts tailings;

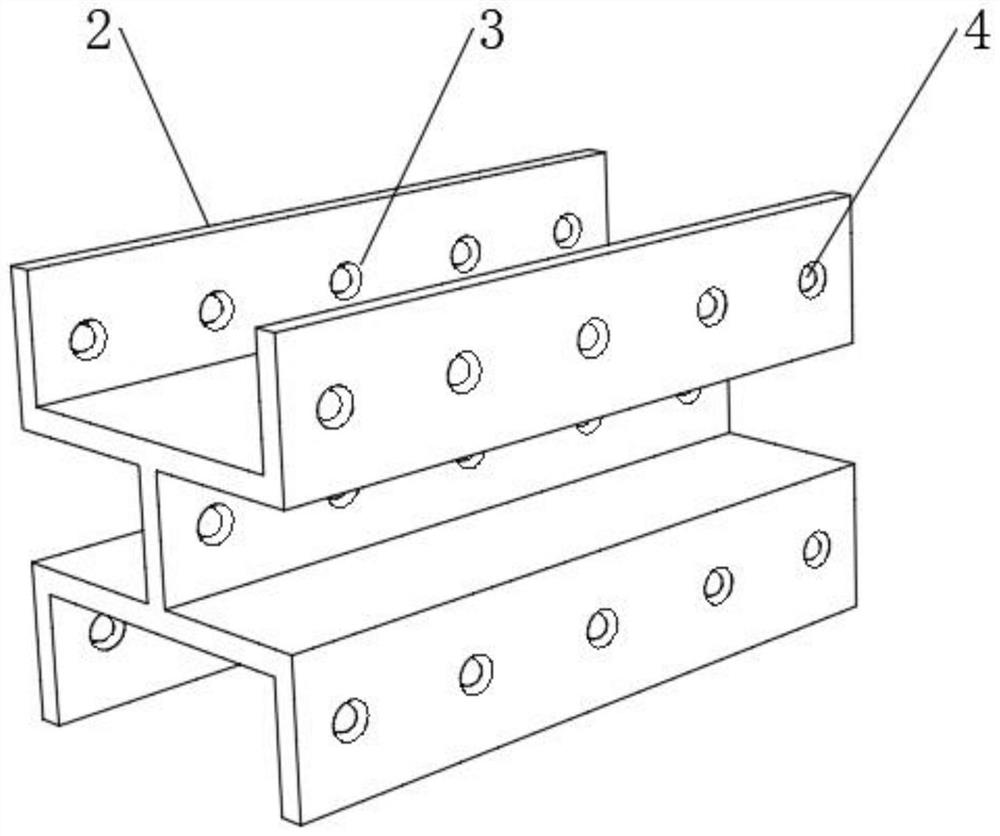

[0047] The inorganic thermal insulation material 2 is provided with a plurality of uniformly distributed through-holes 3 , and the through-holes 3 are arranged horizontally along the width direction of the block body 1 , and self-adaptive isolation balls 4 are arranged in the through-holes 3 .

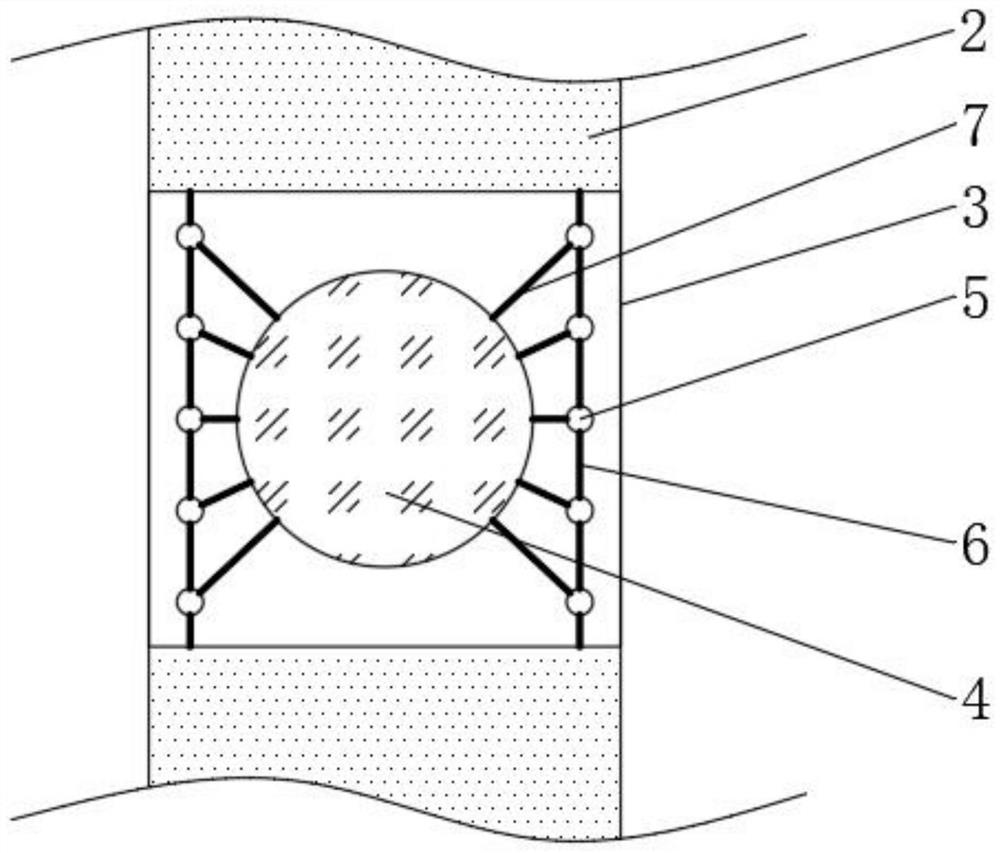

[0048] see image 3 , the left and right sides of the sel...

Embodiment 2

[0062] see Figure 1-2 , an adaptive transposition type thermal insulation concrete block, comprising a block body 1 and an inorganic thermal insulation material 2 embedded in the block body 1, characterized in that: the block body 1 uses the following raw materials in parts by weight: cement 80 parts, 20 parts of mineral powder, 30 parts of fly ash, 50 parts of vitrified microspheres, 3 parts of polyacrylamide, 3 parts of polyvinyl alcohol, 3 parts of cellulose, 2 parts of PP fiber, 3 parts of superplasticizer, aluminum 3 parts powder, 4 parts accelerator, 2 parts triethanolamine, 3 parts sodium sulfate, 35 parts tailings.

[0063] A method for preparing an adaptive transposition type thermal insulation concrete block, comprising the following steps:

[0064] S1. After placing a suitable inorganic thermal insulation material 2 in the block mold in advance, weigh the raw materials of the block body 1, mix them evenly, and then pour them into the block mold;

[0065] S2. Heat...

Embodiment 3

[0070] see Figure 1-2 , an adaptive transposition type thermal insulation concrete block, comprising a block body 1 and an inorganic thermal insulation material 2 embedded in the block body 1, characterized in that: the block body 1 uses the following raw materials in parts by weight: cement 100 parts, 30 parts of mineral powder, 45 parts of fly ash, 60 parts of vitrified microspheres, 5 parts of polyacrylamide, 5 parts of polyvinyl alcohol, 5 parts of cellulose, 3 parts of PP fiber, 5 parts of superplasticizer, aluminum 5 parts powder, 8 parts accelerator, 4 parts triethanolamine, 7 parts sodium sulfate, 50 parts tailings.

[0071] A method for preparing an adaptive transposition type thermal insulation concrete block, comprising the following steps:

[0072] S1. After placing a suitable inorganic thermal insulation material 2 in the block mold in advance, weigh the raw materials of the block body 1, mix them evenly, and then pour them into the block mold;

[0073] S2, heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com