Optical cable external diameter detection device and application thereof

A detection device and optical cable technology, applied in the field of optical fiber production equipment, can solve the problems of low production efficiency, increase production cost expenditure, consume a lot of manpower and material resources, etc., to improve production efficiency, avoid wear and tear or even break, and achieve high automation and cost-effectiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

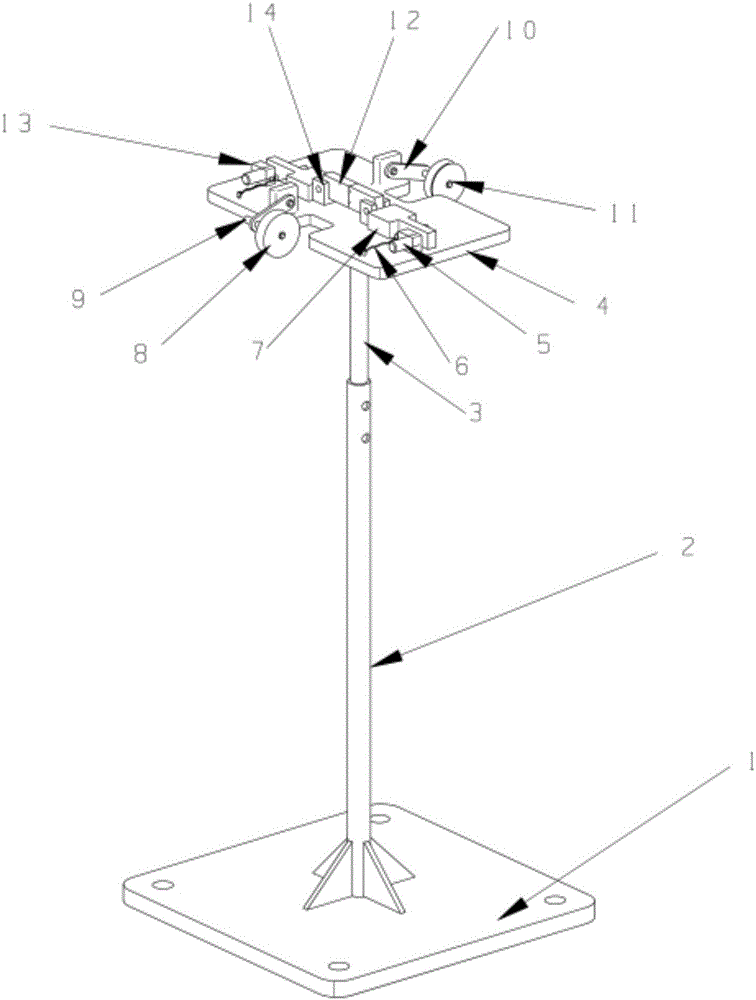

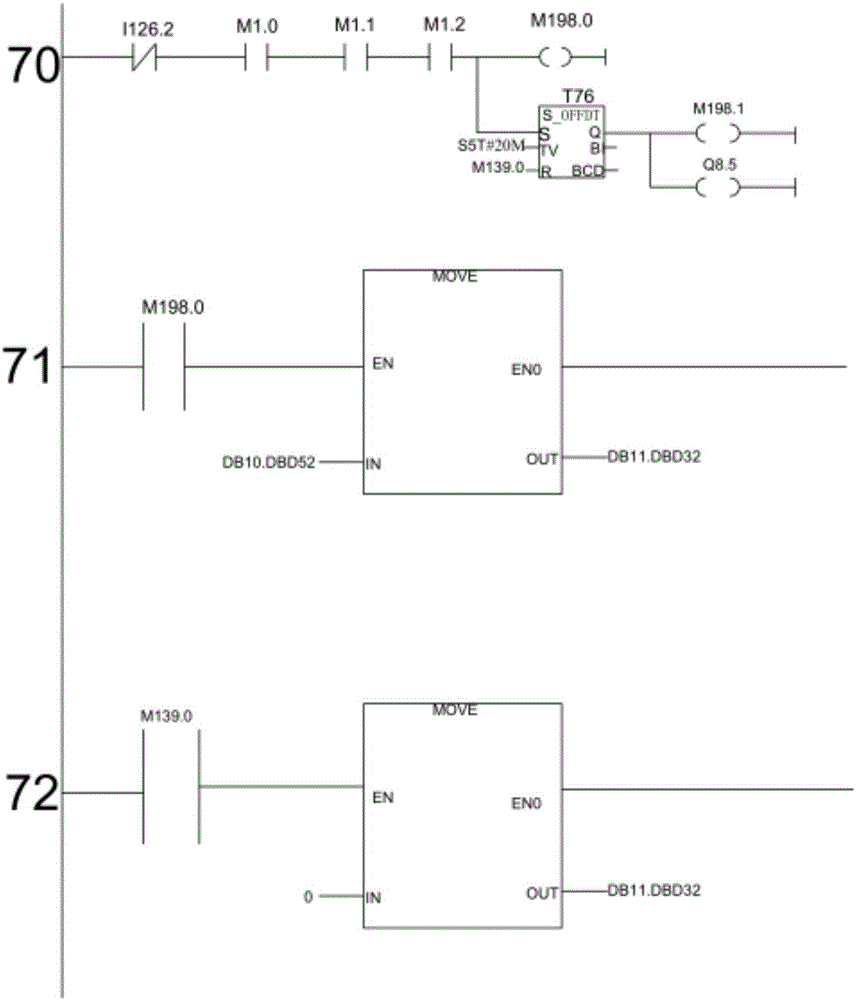

[0044] Such as figure 1 shown.

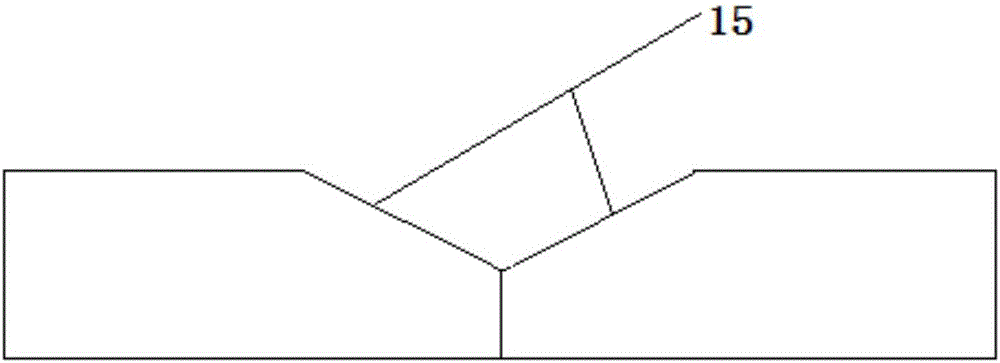

[0045] A device for detecting the outer diameter of an optical cable, comprising a supporting plate 4; the supporting plate 4 is provided with two detection doors; the detection door includes a rotating block 7 and a reset device; the rotating block 7 is provided with a mold 12, and the two detection doors The mold 12 on the door is docked and set, and the butt joint gap of the two molds 12 is provided with a through hole for the optical fiber to pass through; one side of the rotating block 12 is provided with a normally closed proximity switch, and the normally closed proximity switch is connected to the programmable controller. Input contact connection.

[0046] When the optical fiber with protrusions on the surface passes through the through hole, the protrusion will drive the rotating block 7 to rotate in the horizontal direction through the mold 12. After the protrusion passes through the through hole, the reset device will reset the rota...

Embodiment 2

[0048] The optical cable outer diameter detection device as described in Embodiment 1, the difference is that a mold frame 14 is arranged on the rotating block 7, and the mold 12 is embedded in the mold frame 14; the docking of the two molds 12 A plurality of through holes with different specifications are arranged on the gap. The advantage of the design here is that different molds 12 can be configured in the mold frame 14 according to the production needs, which improves the versatility of the device; the production of optical fibers with different specifications can be realized on the same mold 12, and one mold can be used for multiple purposes, which improves production efficiency .

Embodiment 3

[0050] The optical cable outer diameter detection device as described in Embodiment 1, the difference is that the optical cable outer diameter detection device also includes guide wheels 8 arranged at the front and rear ends of the supporting plate 4, and the two detection doors are arranged on the left and right sides of the guide wheels Both sides; the guide wheel 8 is arranged on the pallet 4 through the adjustable arm 10 . The guide wheel 8 provides lifting force for the optical fiber to prevent the optical fiber from breaking. The adjustable arm 10 enables height adjustment of the guide wheel 8 . Guide wheel 8 is 1100 aluminum alloy material, and mold 12 is C1100 red copper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com