Method and device for testing shear strength of rock and concrete bond interface

A technology of shear strength and concrete, applied in the field of geotechnical engineering, can solve the problems of high performance requirements of testing machines, high cost, and many concrete raw materials, and achieve the effect of simple and easy operation, scientific and reasonable equipment, and less raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

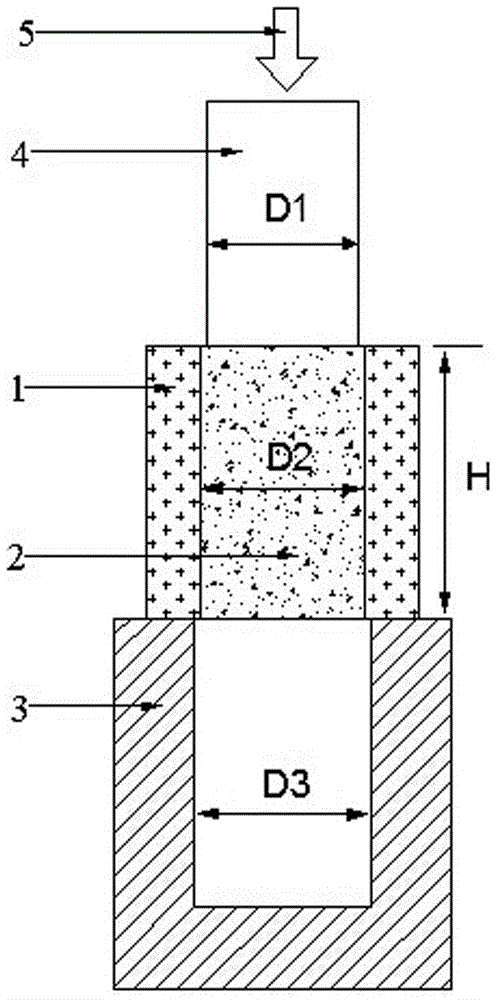

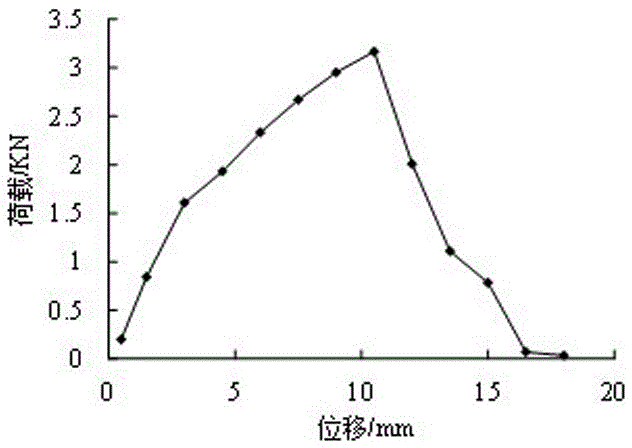

[0034] A. Make hollow rock sample 1, hollow rock sample 1 is marble, hollow rock sample 1 has an outer diameter of 100mm and an inner diameter of D 2 The concrete test sample 2 is filled in the cavity of the hollow rock sample 1, and the raw material and the ratio of the concrete test sample 2 are water: cement: fine sand = 0.4:1:1, filling After completion, vibrate and compact on a vibrating table, and flatten the upper and lower ends of the concrete test sample 2 to make a test sample composed of a hollow rock sample 1 and a concrete test sample 2;

[0035] B. Place the test sample in the curing room for curing, the curing temperature is 35°C, the humidity is 80%, and the curing time is 14 days;

[0036] C. Place the cured test sample on the measuring table 3, and make the test sample coincide with the center axis of the measuring table 3; the outer diameter of the measuring table 3 is 150mm, and the cylindrical groove diameter of the measuring table 3 is 53mm; the loading colu...

Embodiment 2

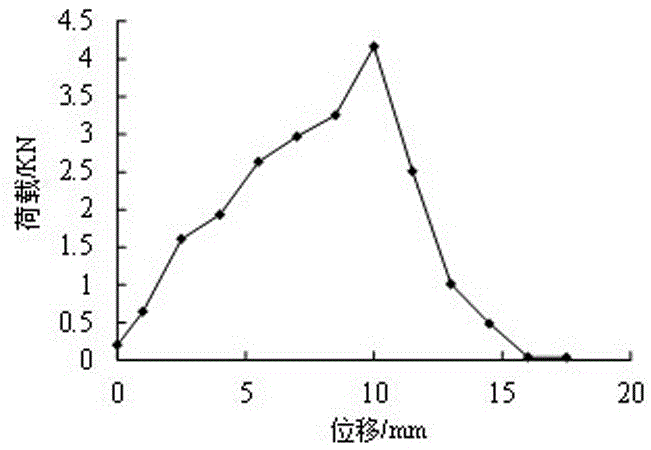

[0040] A. Make hollow rock sample 1, hollow rock sample 1 is marble, hollow rock sample 1 has an outer diameter of 100mm and an inner diameter of D 2 The concrete test sample 2 is filled in the cavity of the hollow rock sample 1, and the raw material and the ratio of the concrete test sample 2 are water: cement: fine sand = 0.25:1:1, filling After completion, vibrate and compact on a vibrating table, and flatten the upper and lower ends of the concrete test sample 2 to make a test sample composed of a hollow rock sample 1 and a concrete test sample 2;

[0041] B. Place the test sample in the curing room for curing, the curing temperature is 35°C, the humidity is 80%, and the curing time is 14 days;

[0042] C. Place the cured test sample on the measuring table 3, and make the test sample coincide with the center axis of the measuring table 3; the outer diameter of the measuring table 3 is 150mm, and the cylindrical groove diameter of the measuring table 3 is 53mm; the loading col...

Embodiment 3

[0046] A. The hollow rock sample 1 is made, the hollow rock sample 1 is granite, the outer diameter of the hollow rock sample 1 is 100mm, and the inner diameter is D 2 The concrete test sample 2 is filled in the cavity of the hollow rock sample 1, and the raw material and the ratio of the concrete test sample 2 are water: cement: fine sand=0.4:1:1, filling After completion, vibrate and compact on a vibrating table, and flatten the upper and lower ends of the concrete test sample 2 to make a test sample composed of a hollow rock sample 1 and a concrete test sample 2;

[0047] B. Place the test sample in the curing room for curing, the curing temperature is 35°C, the humidity is 80%, and the curing time is 14 days;

[0048] C. Place the cured test sample on the measuring table 3, and make the test sample coincide with the center axis of the measuring table 3; the outer diameter of the measuring table 3 is 150mm, and the cylindrical groove diameter of the measuring table 3 is 53mm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com