Light guide plate, backlight module group, and display device

A technology of backlight module and light guide plate, which is applied in the fields of backlight module, display device and light guide plate, and can solve the problem of misalignment between the light-emitting surface of LED lamp and the light-incoming surface of the light guide plate, and the inability of light to enter the light guide plate effectively. Reduce the brightness and uniformity of the backlight source, etc., to achieve the effect of improving the luminous effect, reducing uneven brightness, and improving brightness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

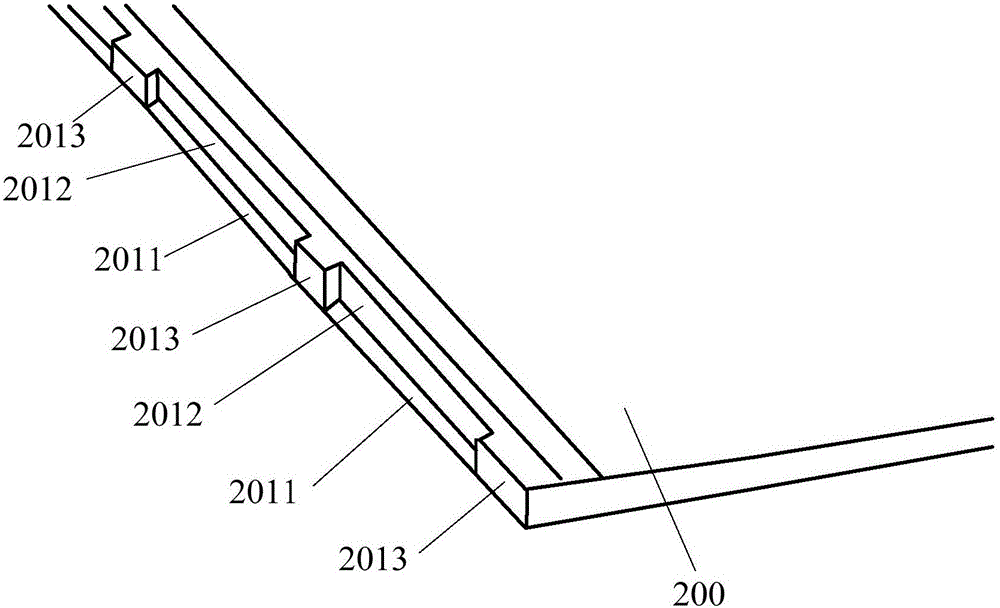

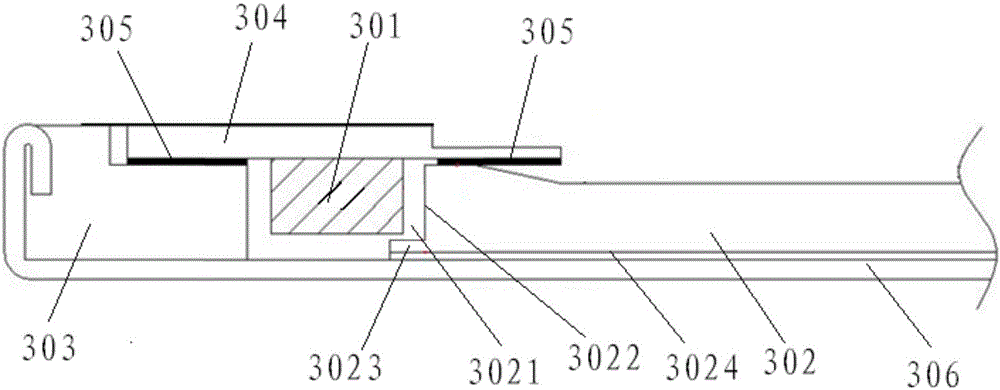

[0020] The present invention firstly provides a light guide plate with a structure such as figure 2 As shown, a groove for accommodating at least a part of LED lamps is provided on the light incident side of the light guide plate 200 .

[0021] It can be seen from the above that the light guide plate provided by the present invention has a groove for accommodating the LED lamp. The LED lamp is assembled in the groove, and the distance between the light guide plate and the light guide plate is shortened. At the same time, the contact area between the LED lamp and the light guide plate is Increase, so that the light emitted by the LED lamp can enter the light guide plate more, so that the brightness of the backlight module using this light guide plate can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com