Multi-core planar optical waveguide structure and coupling structure thereof

A planar optical waveguide and coupling structure technology, applied in the field of optical waveguide coupling, can solve the problems of high packaging cost, complex process, and difficulty in large-scale integration, and achieve the requirements of improving alignment tolerance, reducing cost, and reducing process accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

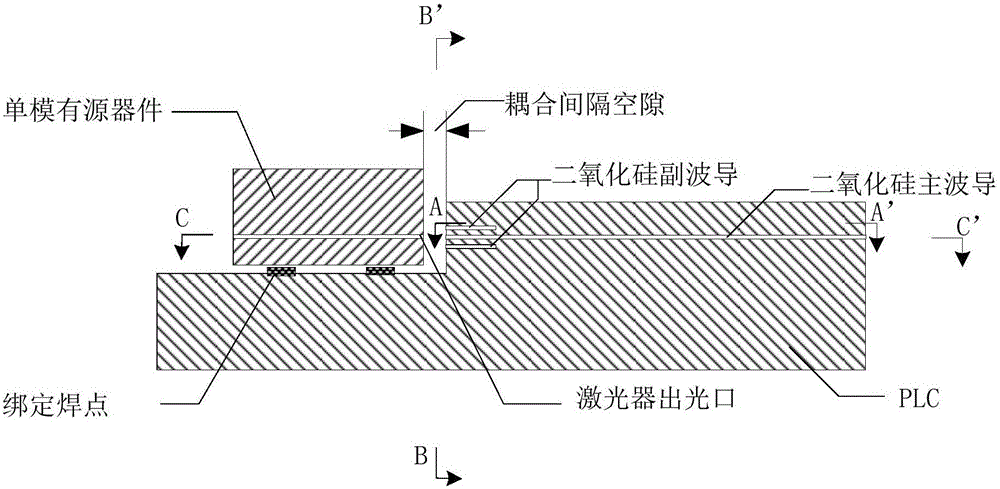

[0043] Embodiment 1 of the present invention provides a multi-core planar optical waveguide structure, such as figure 1 As shown, the multi-core planar optical waveguide structure includes:

[0044] The planar optical waveguide includes a silicon dioxide main waveguide for transmitting optical signals, and a secondary waveguide for assisting light entering;

[0045] The secondary waveguide includes one or more silica secondary waveguides, and the silica secondary waveguide is arranged according to a preset center distance from the silica main waveguide.

[0046] Wherein, the center distance is used to ensure that the one or more secondary silica waveguides and the main silica waveguide produce sufficient coupling effect on the light receiving surface.

[0047] The planar optical waveguide structure including one or more silica secondary waveguides proposed in the embodiments of the present invention can complete the passive alignment and direct coupling of the laser to the PL...

Embodiment 2

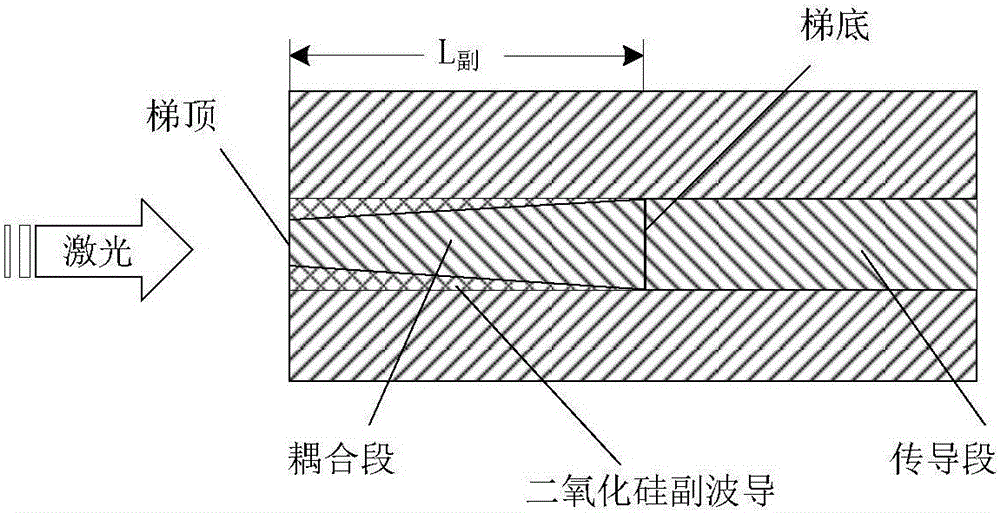

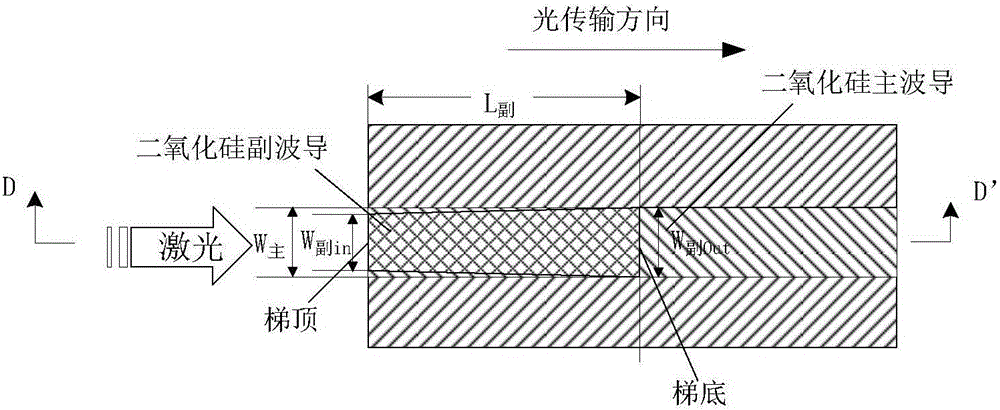

[0050] Based on the multi-core planar optical waveguide structure described in Embodiment 1, Embodiment 2 of the present invention specifically describes the composition of one of the optional silica secondary waveguides, as image 3 , Figure 4 and Figure 5 Shown:

[0051] The planar optical waveguide includes a silicon dioxide main waveguide for transmitting optical signals, and a secondary waveguide for assisting light entering;

[0052] The secondary waveguide specifically includes two sub-sub-waveguides, wherein the first sub-sub-waveguide is located on the upper side of the silica main waveguide, the second sub-sub-waveguide is located on the lower side of the silica main waveguide, and the two sub-sub-waveguides are located on the lower side of the silica main waveguide. The silicon oxide secondary waveguide and the silicon dioxide main waveguide are arranged according to a preset center distance.

[0053] Wherein, the center distance is used to ensure that the one ...

Embodiment 3

[0068] Based on the multi-core planar optical waveguide structure described in Embodiment 1, Embodiment 3 of the present invention specifically describes the composition of one of the optional silica secondary waveguides, as Figure 7 , Figure 8 and Figure 9 Shown:

[0069] The planar optical waveguide includes a silicon dioxide main waveguide for transmitting optical signals, and a secondary waveguide for assisting light entering;

[0070] The sub-waveguides specifically include eight sub-sub-waveguides, wherein the first sub-sub-waveguide 01 is located on the upper side of the silica main waveguide; the second sub-sub-waveguide 02 is located on the lower side of the silica main waveguide; The third sub-waveguide 03 is located on the left side of the silica main waveguide; the fourth sub-sub-waveguide 04 is located on the right side of the silica main waveguide; the fifth sub-sub-waveguide 05 is located on the side of the silica main waveguide The upper left side, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com