Photochromic glasses with liquid crystal thin film protection lenses and manufacturing method of protection lenses

A liquid crystal film and protective lens technology, which is applied in the field of production of photochromic mirrors with liquid crystal film protective sheets and protective lenses, can solve the problems of easy deformation and damage of the lens, and achieve the goal of not being easily scratched, avoiding eye diseases, and low maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

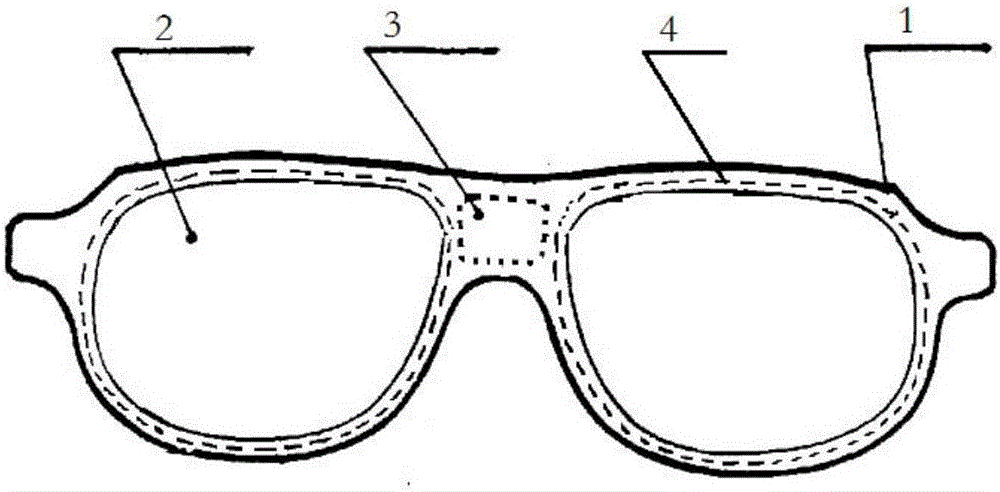

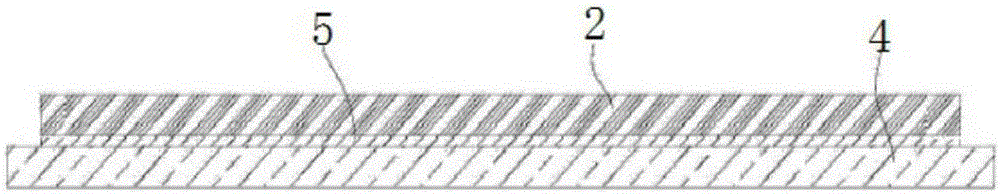

[0027] see figure 1 and figure 2 , figure 1 It is a structural schematic diagram of a color-changing mirror with a liquid crystal film protection sheet of the present invention; figure 2 It is a schematic cross-sectional structure diagram of a protective lens of a photochromic mirror with a liquid crystal film protective sheet of the present invention. Such as figure 1 and figure 2 As shown, the said a kind of photochromic mirror with liquid crystal film protection sheet includes: including spectacle frame 1, flexible liquid crystal film 2, control module 3 and liquid crystal film protection sheet 4, and said flexible liquid crystal film 2 includes left flexible A liquid crystal film (not shown) and a right flexible liquid crystal film (not shown), the liquid crystal film protection sheet 4 includes a left liquid crystal film protection sheet (not shown) and a right liquid crystal film protection sheet (not shown), the The shape of the left flexible liquid crystal film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com