Composite suspension insulator

A technology of suspension insulators and insulating rods, which is applied in the field of high-voltage electric ceramics, can solve the problems of poor hydrophobicity, poor anti-pollution performance, and damage to the operating life of lines, and achieve the level of enhanced insulation, good insulation performance, and pollution flashover prevention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

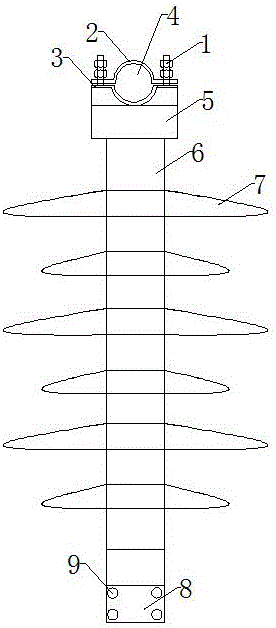

[0015] Such as figure 1 As shown, a composite suspension insulator includes a flange 5 and an umbrella-shaped skirt 7. The flange 5 is provided with a crimping seat, and the crimping seat is provided with a crimping groove 4. The The crimping seat is fixed together by bolts 1, the flange 5 is set on the insulating rod 6, and the insulating rod 6 is provided with an umbrella skirt 7, and the bottom of the insulating rod 6 is provided with a metal plate 8. The metal plate 8 is provided with wiring holes 9 .

[0016] The crimping seat is composed of an upper splint 2 and a lower splint 3 .

[0017] The umbrella skirt 7 is made of rubber.

[0018] The surface of the insulator is coated with a layer of antifouling flash paint.

[0019] There are four wiring holes 9 .

[0020] Method of use: When the present invention is in use: apply a layer of antifouling flash paint on the surface of the insulator with a thickness of 0.3mm, and then place it in a fixed position and fix it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com