Patents

Literature

48results about How to "Improve hydrophobic mobility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

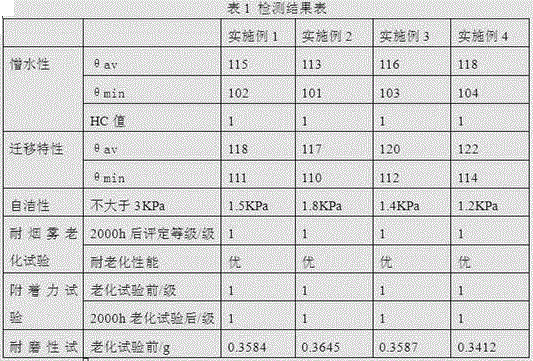

Novel anti-pollution flashover coating for ultra and super high voltage insulator

ActiveCN105086820AReduce the temperaturePrevent escapeFireproof paintsAntifouling/underwater paintsSolventSurface-active agents

The invention belongs to the technical field of functional coatings and particularly relates to a novel anti-pollution flashover coating for an ultra and super high voltage insulator. The novel anti-pollution flashover coating comprises, by mass, 40%-50% of room temperature vulcanized silicone rubber, 5%-10% of titanate coupling agent, 2%-6% of composite fire retardant, 5%-12% of modified composite reinforcing agent, 2%-4% of nano TiO2, 0.5%-1% of surface active agent, 1%-5% ofhexamethyldisilazane, 0.2%-0.5% of antifoaming agent, 0.3%-0.6% of catalyst, 0.3%-0.6% of cross-linking agent and the balance solvent. The prepared anti-pollution flashover coating is sprayed on the surface of the cleaned ceramic insulator, and the coating can be used after being naturally cured for 96 hours under the condition of 25 DEG C+ / -2 DEG C and 40%-70% of RH. According to the anti-pollution flashover coating, after the sprayed anti-pollution flashover coating is completely cured, the contact angle is not smaller than 135 degrees.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Method for producing bird damage resistant silicon fluoride insulated sleeve

ActiveCN101593584AProtection against arcingProtective dischargePlastic/resin/waxes insulatorsInsulating bodiesSilicon dioxideFluorine containing

The invention discloses a method for producing a bird damage resistant silicon fluoride insulated sleeve. The production method comprises the following steps: roller-milling a mixture formed by 10 to 30 percent of fluorine containing dimethyl polysiloxan, 40 to 50 percent of ethylene containing dimethyl polysiloxan, 20 to 40 percent of reinforcing filler silicon dioxide and electrical erosion resistant filler aluminum hydroxide, and 1 to 5 percent of dye in a banbury mixer at a temperature of between 70 and 120 DEG C and under a pressure of less than or equal to 0.2Mpa for 1 hour; adding 1 to 3 percent of vulcanizer in the mixture roller-milled by the banbury mixer and evenly mixing; roller-milling the mixture in a roller mixer for 1 hour, and then milling the mixture; re-milling the vulcanizer containing mixture milled by the roller mixer; rolling-extruding the mixture by an extrusion forming machine for forming; and finally, two-stage vulcanizing the mixture in a vulcanizing furnace at a temperature of 180 DEG C for 2 hours to obtain the silicon fluoride insulated sleeve, cutting the silicon fluoride insulated sleeve into certain length, and sealing the tenon by a bonding agent when the sleeve is used. The invention is a method for producing a highly insulated bird damage resistant silicon fluoride insulated sleeve.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +2

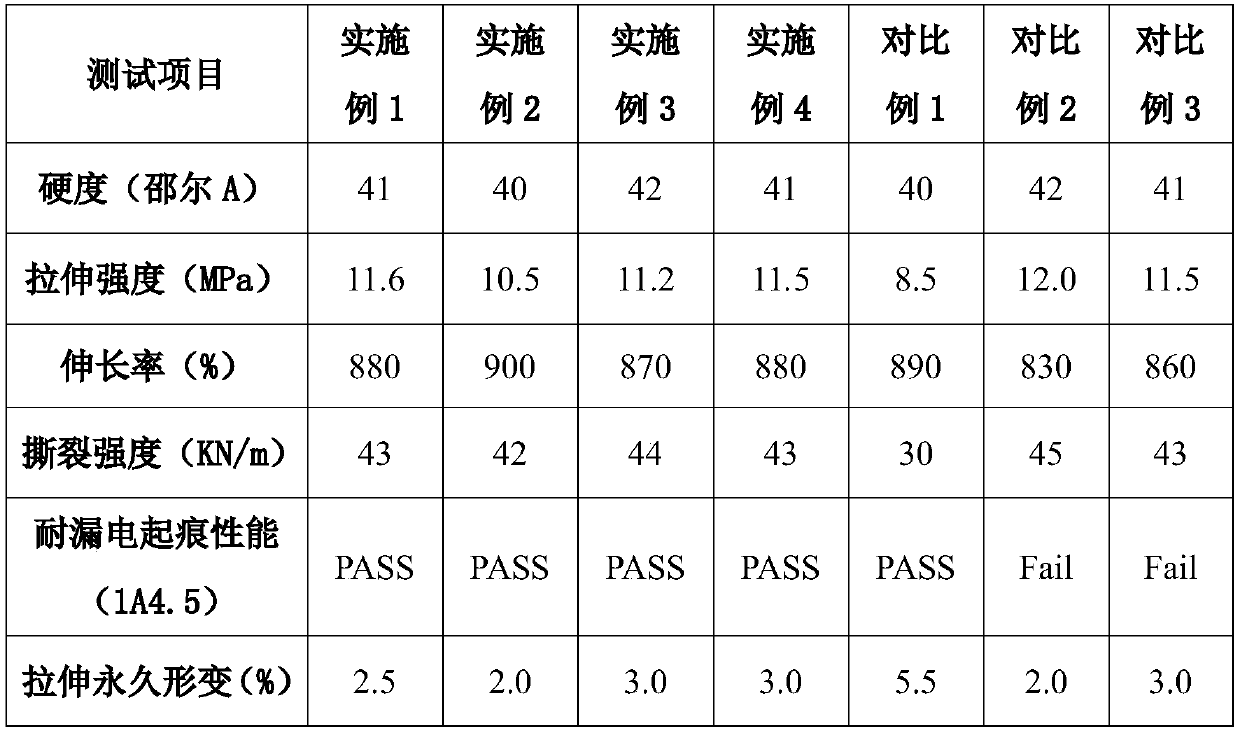

Liquid silicone rubber composition for cold shrink cable and preparation method of liquid silicone rubber composition

InactiveCN107858002AImprove heat resistanceImprove heat aging resistancePolydimethylsiloxaneDimethyl siloxane

The invention discloses a liquid silicone rubber composition for a cold shrink cable and a preparation method of the liquid silicone rubber composition. The composition is prepared from, in parts by mass, 100 parts of vinyl polydimethylsiloxane, 0.5-5 parts of high vinyl silicone oil, 0.1-10 parts of a cross-linking agent, 0.01-10 parts of an anti-aging assistant, 20-50 parts of fumed silica, 0.1-2 parts of phenyl silicone oil with high phenyl content, 0.001-0.5 part of aminobenzotriazole or a derivative of aminobenzotriazole, 0.001-0.5 part of a platinum catalyst and 0.001-0.5 part of an inhibitor, and the preparation method includes the steps of: preparing base glue, preparing A glue and B glue, mixing the A glue and the B glue and the like. According to the liquid silicone rubber composition for the cold shrink cable and the preparation method of the liquid silicone rubber composition, the liquid silicone rubber composition for the cold shrink cable has the advantages of excellent ablation resistance, good tracking resistance and excellent physical properties.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP +1

Improved 3 type slow release long-acting super-hydrophobic anti-contamination flashover coating

ActiveCN106675398AImprove hydrophobic mobilityImprove self-cleaning abilityAntifouling/underwater paintsPaints with biocidesChemistryOxide

The invention discloses an improved 3 type slow release long-acting super-hydrophobic anti-contamination flashover coating which comprises the following raw materials in parts by weight: 35-45 parts of hydroxypropyl terminal fluorine-containing polysiloxane, 20-30 parts of hydrogen terminal polysiloxane, 55-65 parts of 107 silicone rubber, 20-30 parts of hydrophobic fumed silica, 3-5 parts of nanometer zinc oxide, 2-4 parts of oil amino oleate, 4-6 parts of wollastonite powder, 1-3 parts of ketoxime cross-linking agent, 5-10 parts of dimethylamino propylamine, 1-2 parts of silane coupling agent, 3-6 parts of aluminum hydroxide and 165-175 parts of organic solvent. The improved 3 type slow release long-acting super-hydrophobic anti-contamination flashover coating disclosed by the invention has the advantages of strong mechanical property, long service life as long as 15 years, excellent fire resistance reaching up to FV-1 level, excellent salt spray and ageing resistance, excellent stain resistance, capability of acting under haze polluted weather, capability of achieving expected anti-contamination flashover effect and capability of preventing contamination flashover accident from happening.

Owner:STATE GRID CORP OF CHINA +1

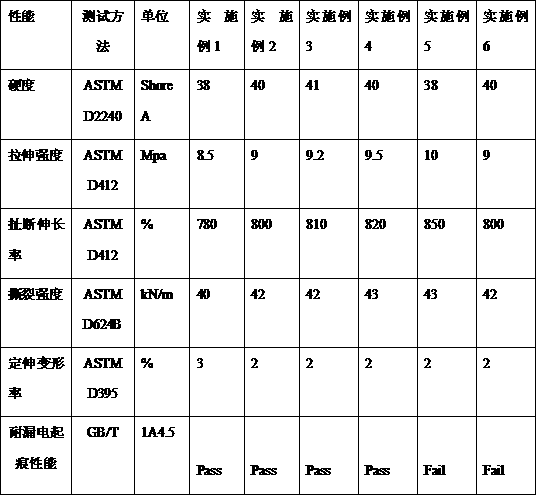

Silicone rubber for cold-shrinkable power cable accessory and preparation method of silicone rubber

InactiveCN111349342AGood physical and mechanical propertiesImprove high temperature resistancePlastic/resin/waxes insulatorsPolymer scienceTert butyl

The invention discloses silicone rubber for a cold-shrinkable type power cable accessory, wherein the silicone rubber comprises the following components in parts by weight: 140 to 160 parts of methylvinyl silicone rubber raw rubber, 40 to 60 parts of white carbon black, 0.5 to 2 parts of nano titanium dioxide, 0.5 to 2 parts of nano cerium oxide, 1 to 2 parts of phenyl silicone oil, 4 to 6 partsof hexamethyldisilazane, 2 to 3 parts of deionized water, 0.2 to 1 part of a mold release agent, 0.1 to 0.5 part of alcohol modified chloroplatinic acid, 0.1 to 0.5 part of benzotriazole, and 0.5-2 parts of 2,5-dimethyl-2,5-di-tert-butyl hexane peroxide. The invention further provides a preparation method of the silicone rubber for the cold-shrinkable type power cable accessory. The silicone rubber for the cold-shrinkable type power cable accessory has excellent physical and mechanical properties, high temperature resistance, tracking resistance and the like.

Owner:GUANGDONG POLYSIL TECH CO LTD

Mildew-proof formaldehyde-removing caulking agent and preparation method and application method thereof

InactiveCN105272025AImprove hydrophobic mobilityImprove self-cleaning abilityAluminum silicateDimethyl siloxane

The present invention discloses a mildew-proof formaldehyde-removing caulking agent, a base material is prepared as follows: first, white Portland cement is crushed to 300-500 mesh, the white Portland cement is added with glass beads, hydroxypropyl methyl cellulose, inorganic aluminum salt waterproofing agent, modified nano titanium dioxide, nano-zinc oxide and magnesium aluminum silicate for even stirring; an assistant material is prepared as follows: ethylene-vinyl acetate copolymer, acrylic resin, polydimethylsiloxane silicon, RTV organic silicone and a brightener are mixed and stirred evenly; an iron oxide pigment is chosen according to the caulking agent color classification, the base material is added into a high speed shear mixer, at a shear stirring state, the assistant material and the iron oxide pigment are successively added, the shear rate is 6000-8000RPM, time is 45min-90min, and the mildew-proof formaldehyde-removing caulking agent is obtained by discharging while stirring. A caulking space is cleaned up, caulking seams are sprayed with primary water for wetting, then the caulking agent and water are mixed in the mass ratio of 1: (0.4-0.6) to prepare a viscous and dense material, the viscous and dense material is filled between ceramic tiles, after the viscous and dense material is dried, the primary water is sprayed again, and the water is natural dried.

Owner:孙军

Building top layer joint mixture additive and preparation method

InactiveCN105174802AEnhance hydrophobicityImprove hydrophobic mobilityHydroxypropylmethyl celluloseAluminum magnesium silicate

The invention discloses a building top layer joint mixture additive. The building top layer joint mixture additive is characterized by comprising, by mass, 2-3 parts of ethylene-vinyl acetate copolymer, 8-12 parts of glass beads, 2-2.4 parts of fumed silica, 1-1.5 parts of acrylic resin, 3-6 parts of hydroxypropyl methyl cellulose, 1-1.3 parts of inorganic aluminum salt waterproof agent, 1-1.2 parts of organic silicon water repellent, 0.5-1.5 parts of aluminum-magnesium silicate, 1.5-1.9 parts of RTV organic silica gel and 2-3 parts of lignin fiber. The ethylene-vinyl acetate copolymer and the acrylic resin are ultrasonically dispersed for 0.5-1 h, then, the fumed silica, the inorganic aluminum salt waterproof agent, the organic silicon water repellent, the aluminum-magnesium silicate and the RTV organic silica gel are added for high-speed stirring and dispersing for 1-1.5 h, finally the glass beads, the lignin fiber and the hydroxypropyl methyl cellulose are added, and the temperature is slowly decreased to reach the room temperature to obtain the building top layer joint mixture additive.

Owner:孙军

Revise method for polluted area distribution map of composite insulator based on equivalent salt deposit density

InactiveCN105037981ANot perishableExcellent foaming abilityMaterial analysis by electric/magnetic meansComposite insulatorsChlorinated polyethylene

The invention discloses a revise method for a polluted area distribution map of a composite insulator based on equivalent salt deposit density. The composite insulator comprises raw materials in parts by weight: 120-150 parts of chlorinated polyethylene rubber, 12-15 parts of a curing agent, 3-5 parts of an oxidant 1010, 5-8 parts of zinc stearate, 3-5 parts of an adjustor and 3-5 parts of a flame retardant. The composite insulator further comprises 5-8 parts of a functional material which comprises coco fatty acid diethanol amide and hydrogen peroxide. The invention discloses the composite insulator which is good in texture toughness, good in insulating property and long in service life and a detection method for equivalent salt deposit density. The insulator has excellent hydrophobicity, hydrophobic migration, high mechanical strength, good wear resistance and external destruction resistance, and can be used for satisfying the processing and operating requirements of the insulator.

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN

Processing technology of slow-release long-acting super hydrophobic anti-pollution flashover coating

ActiveCN106811116AImprove hydrophobic mobilityTo achieve the purpose of slow-release anti-pollution flashoverCoatingsPolymer sciencePropylamine

The invention discloses a processing technology of a slow-release long-acting super hydrophobic anti-pollution flashover coating. The processing technology comprises the following steps: first, preparing hydroxypropyl-terminated fluorinated polysiloxane, hydroxyl-terminated polysiloxane and hydrophobic fumed silica; second, adding the hydroxypropyl-terminated fluorinated polysiloxane and hydroxyl-terminated polysiloxane together with 107 silicone rubber, nano zinc oxide, oil amino oleate, mica powder and aluminum hydroxide into a mixer, stirring uniformly, and grinding for 3-4 times on a three-roller machine to obtain a uniform sizing material; third, adding the uniform sizing material into a kneading machine, adding the hydrophobic fumed silica, heating to 145-150 DEG C, kneading for 1-2 hours and cooling to 20-30 DEG C; and after that, adding a ketoxime crosslinking agent, dimethylamino propylamine, a silane coupling agent and an organic solvent, and stirring uniformly to obtain slow-release long-acting super hydrophobic anti-pollution flashover coating. In the coating prepared by the preparation method disclosed by the invention, the aims of slow release and pollution prevention can be achieved through the combination of the hydroxypropyl-terminated fluorinated polysiloxane and hydroxyl-terminated polysiloxane, and the hydrophobicity transfer of the coating can be remarkably improved.

Owner:STATE GRID CORP OF CHINA +1

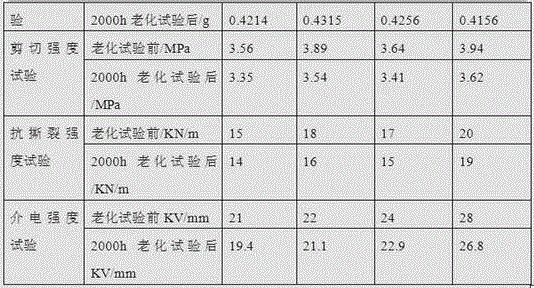

A polyolefin insulator material with long-lasting hydrophobic properties

ActiveCN110423394BHas long-lasting hydrophobic propertiesGood compatibilityPolymer sciencePolyolefin

A polyolefin insulator material with long-term water-repellent properties, composed of 40-55 parts of polyethylene, 30-50 parts of polypropylene, 8-20 parts of decabromodiphenylethane, 3-7 parts of trioxide The composition consists of antimony, 0.2-0.5 parts of antioxidant, 0.5-1.5 parts of silicone, 0.2-0.5 parts of light stabilizer and 1-10 parts of modified silicone oil. The modified silicone oil composition is prepared by reacting fatty acid and side-chain amino silicone oil under nitrogen protection at 80-150°C for several hours, and is used as a hydrophobic migration agent for polyolefin insulating materials. The invention is used for the polyolefin insulator sheath / sheath, which meets the requirements of the insulator on electrical insulation, flame retardancy and mechanical performance, and also endows it with long-term and effective performances such as hydrophobicity, hydrophobicity migration and antifouling.

Owner:NANJING UNIV +1

Environment-friendly wall surface joint mixture and preparing method and using method thereof

InactiveCN105174812AImprove hydrophobic mobilityDifficult to attach dustBuilding repairsHydroxypropylmethyl celluloseBrown iron oxide

The invention discloses an environment-friendly wall surface joint mixture. To obtain the environment-friendly wall surface joint mixture, base materials are prepared firstly, and then auxiliary materials are prepared. During base material preparation, quartz sand is smashed to be 300-500 meshes firstly, and then glass beads, hydroxypropyl methyl cellulose, an inorganic aluminum salt water-proofing agent and aluminium-magnesium silicate are added and evenly stirred. During auxiliary material preparation, an ethylene-vinyl acetate copolymer, acrylic resin, fumed silica, RTV organic silica gel and a brightener are mixed and stirred evenly. Iron oxide pigments are selected in a classified mode according to the color of the joint mixture, the base materials are added to a high-speed shearing mixer, the auxiliary materials and the iron oxide pigments are added in sequence in the shear-stirring state, shearing speed is 6000-8000 RPM, shearing time is 45-90 min, and the material obtained after stirring is the joint mixture. Joint space is cleared, then water is sprayed onto a joint seam once to wet the joint seam, then the joint mixture and water are mixed based on the mass ratio of 1:0.4-0.6 to generate a thick material which is placed between ceramic tiles, water is sprayed again after the thick material is dried, and users just need to wait for natural drying.

Owner:孙军

Joint mixture stabilizer for glaze polished bricks and preparing method

The invention discloses a joint mixture stabilizer for glaze polished bricks. The joint mixture stabilizer is characterized by being prepared from, by mass, 2-3 parts of ethylene-vinyl acetate copolymer, 8-12 parts of glass beads, 1-1.5 parts of acrylic resin, 3-6 parts of hydroxypropyl methyl cellulose, 1-1.3 parts of inorganic aluminum salt waterproof agents, 0.5-1.5 parts of aluminum-magnesium silicate, 1.5-1.9 parts of RTV organic silica gel and 1.8-2.2 parts of acrylic acid rubber powder. The acrylic acid rubber powder, the ethylene-vinyl acetate copolymer and the acrylic resin are subjected to ultrasonic dispersion for 0.5-1 h, then the inorganic aluminum salt waterproof agents, the aluminum-magnesium silicate and the RTV organic silica gel are added and stirred at a high speed for dispersion for 1-1.5 h, finally the glass beads and the hydroxypropyl methyl cellulose are added, and the joint mixture stabilizer is obtained after the temperature is slowly reduced to the room temperature.

Owner:孙军

Building curtain wall joint mixture, preparation method and use method

The invention discloses a building curtain wall joint mixture. A base material is prepared by smashing white Portland cement and white Portland cement into 300-500 meshes, adding glass beads, hydroxypropyl methyl cellulose, an inorganic aluminium salt waterproof agent and aluminium-magnesium silicate, and conducting even stirring. The auxiliary materials are prepared by mixing and evenly stirring ethylene-vinyl acetate copolymers, acrylic resin, fumed silica, RTV organic silica gel, lignin fiber and brightener. Iron oxide pigment is selected according to the color classification of the joint mixture, the base material is added to a high-speed shearing and stirring machine, the auxiliary materials and the iron oxide pigment are sequentially added in the shearing and stirring state, the shearing speed ranges from 6000 RPM to 8000 RPM, the shearing time ranges from 45 min to 90 min, and the joint mixture is obtained after stirring and discharging. The joint space is cleaned, primary water is sprayed on the joint seam to wet the joint seam, the joint mixture and water are mixed into a thick material according to the mass ratio of 1 to 0.4-0.6, the space between tiles is filled with the thick material, primary water is sprayed again after drying, and natural drying is conducted.

Owner:孙军

Improved slow-release long-acting superhydrophobic anti-pollution flashover coating

ActiveCN106752925AImprove hydrophobic mobilityImprove the lubrication effectFireproof paintsAntifouling/underwater paintsGas phaseHaze pollution

The invention discloses an improved type 2 slow-release long-acting superhydrophobic anti-pollution flashover coating. The improved type 2 slow-release long-acting superhydrophobic anti-pollution flashover coating is prepared from the following raw materials in parts by weight: 35 to 45 parts of hydroxypropyl-terminated fluorine-containing polysiloxane, 20 to 30 parts of hydrogen-terminated polysiloxane, 55 to 65 parts of silicone rubber 107, 20 to 30 parts of hydrophobic gas phase white black carbon, 3 to 5 parts of nanometer zinc oxide, 2 to 4 parts of ethyl oleate, 4 to 6 parts of diatomite, 1 to 3 parts of ketoxime type crosslinking agent, 5 to 10 parts of dimethyl aminopropyl amine, 1 to 2 parts of silane coupling agent, 3 to 6 parts of magnesium hydroxide, and 165 to 175 parts of organic solvent. The improved type 2 slow-release long-acting superhydrophobic anti-pollution flashover coating has the advantages that the mechanical property is strong, the service life is long and can reach 15 years, the flame-retardant property is good and can reach FV-0 class, the salt mist aging-resistant property is good, the anti-pollution property is excellent, the validity is still realized in the haze pollution weather, the expected anti-pollution flashover effect is realized, and the pollution flashover accident is avoided.

Owner:STATE GRID CORP OF CHINA +1

Slow-release type long-acting super-hydrophobic pollution flashover prevention coating

ActiveCN106752924AImprove hydrophobic mobilityImprove mechanical propertiesFireproof paintsAntifouling/underwater paintsHaze pollutionFumed silica

The invention discloses a slow-release type long-acting super-hydrophobic pollution flashover prevention coating. The coating is prepared from the following raw materials in parts by weight: 35-45 parts of terminal hydroxypropyl fluorine-containing polysiloxane, 20-30 parts of terminal hydrogen polysiloxane, 55-65 parts of 107 silicon rubber, 20-30 parts of hydrophobic fumed silica, 3-5 parts of nano zinc oxide, 2-4 parts of oil amino oleate, 4-6 parts of mica powder, 1-3 parts of ketoxime type crosslinking agents, 5-10 parts of dimethyl aminopropyl amine, 1-2 parts of silane coupling agents, 3-6 parts of aluminum hydroxide and 165-175 parts of organic solvents. The slow-release type long-acting super-hydrophobic pollution flashover prevention coating is high in mechanical performance, long in service life which can reach 15 years, high in flame retardancy which can reach FV-0 grade, high in salt fog resistance, high in aging resistance and excellent in stain resistance, and still can exert the effectiveness in weather with haze pollution; the expectant pollution flashover prevention effect can be achieved; the occurrence of pollution flashover accidents is avoided.

Owner:STATE GRID CORP OF CHINA +1

Novel RTV slow-release type long-acting super-hydrophobic pollution-flashover-resistant coating material

InactiveCN108300293AReasonable proportionGood for hydrophobic and anti-fouling flashover performanceFireproof paintsAntifouling/underwater paintsUltra high voltageNano al2o3

The invention relates to a novel RTV slow-release type long-acting super-hydrophobic pollution-flashover-resistant coating material. According to the present invention, nanometer active metal oxides such as nanometer titanium dioxide, nanometer alumina and nanometer zinc oxide are added, and the ratio is optimized, such that the catalytic effect is improved, the improved slow-release type long-acting super-hydrophobic pollution-flashover-resistant coating material can be efficiently processed, the RTV is strengthened, and the mechanical property, the electrical property and the anti-aging property of the coating are improved; the surface structure and the characteristics of the RTV coating are improved with the nanometer powder material, such that the self-cleaning ability and the water repellency of the coating are enhanced, the coating has the good effect, and pollution flashover resistance is easily achieved; and the novel RTV slow-release type long-acting super-hydrophobic pollution-flashover-resistant coating material can provide important practical significance in the anti-fouling work of super high voltage and ultra high voltage power network lines, can save a lot of construction funds and operation and maintenance costs, and can create good social and economic benefits.

Owner:天津市仕翔电气科技有限公司

Accelerant used for cabinet tabletop and wall brick joint mixture and preparation method

The invention discloses accelerant used for a cabinet tabletop and wall brick joint mixture. The accelerant is prepared, by mass, 2-3 parts of ethylene-vinyl acetate copolymers, 8-12 parts of glass beads, 2-2.4 parts of polydimethylsiloxane, 1-1.5 parts of acrylic resin, 3-6 parts of hydroxypropyl methyl cellulose, 1-1.3 parts of inorganic aluminum salt waterproof agents, 0.5-1.5 parts of magnesium aluminum silicate, 1.5-1.9 parts of RTV organic silica gel and 0.4-0.6 part of hydrophobic fumed silica. Ultrasonic dispersion is performed on ethylene-vinyl acetate copolymers, polydimethylsiloxane and acrylic resin for 0.5-1 h, then hydrophobic fumed silica, inorganic aluminum salt waterproof agents, magnesium aluminum silicate and RTV organic silica gel are added, high-speed stirring and dispersing are performed for 1-1.5 h, finally, glass beads and hydroxypropyl methyl cellulose are added, and then the mixture is slowly cooled to indoor temperature to obtain the accelerant.

Owner:孙军

Kitchen gap filler, and preparation method and use method thereof

InactiveCN105236886AImprove hydrophobic mobilityImprove self-cleaning abilityBuilding repairsAluminum magnesium silicateAcrylic resin

The invention discloses a gap filler for heat insulation walls. The gap filler comprises, by mass, 40-50 parts of quartz sand, 10-15 parts of limestone, 2-3 parts of ethylene-vinyl acetate copolymer, 8-12 parts of open-cell expanded perlite, 2-2.4 parts of an organosilicon leveling agent, 1-1.5 parts of acrylic resin, 3-6 parts of hydroxypropyl methyl cellulose, 1-1.3 parts of an inorganic aluminum salt waterproof agent, 0.5-1.5 parts of aluminum magnesium silicate, 1.5-1.9 parts of RTV organic silica gel, 4-6 parts of sodium silicate and 1.8-2.2 parts of an iron oxide pigment. Gap filling spaces are cleaned, gap filling seams are sprinkled with water until moisture, the gap filler and water are mixed according to a mass ratio of 1:(0.4-0.6) and are blended to form a viscous material, the viscous material is filled between tiles, water is sprinkled after the viscous material is dried, and then natural drying is carried out.

Owner:孙军

Improved slow-release long-acting superhydrophobic anti-pollution-flashover paint

ActiveCN106811117AImprove hydrophobic mobilityTo achieve the purpose of slow-release anti-pollution flashoverCoatingsChemistryPollution flashover

The invention discloses an improved Type-1 slow-release long-acting superhydrophobic anti-pollution-flashover paint which is composed of the following raw materials in parts by weight: 35-45 parts of hydroxypropyl-terminated fluorine-containing polysiloxane, 20-30 parts of hydrogen-terminated polysiloxane, 55-65 parts of 107 silicone rubber, 20-30 parts of hydrophobic fumed silica, 3-5 parts of nano zinc oxide, 2-4 parts of amino oleate, 4-6 parts of nano calcium carbonate, 1-3 parts of ketoxime crosslinking agent, 5-10 parts of talcum powder, 1-2 parts of silane coupling agent, 1-2 parts of decabromodiphenyl oxide and 165-175 parts of organic solvent. The improved Type-1 slow-release long-acting superhydrophobic anti-pollution-flashover paint has the advantages of high mechanical properties, long service life (up to 15 years), favorable flame retardancy (Grade FV-0), favorable salt fog aging resistance and excellent pollution resistance, can still be effective in the smog pollution days, achieves the expected anti-pollution-flashover effect, and avoids the pollution flashover accident.

Owner:STATE GRID CORP OF CHINA +1

Weather resistance stabilizing agent of crack filler and preparation method

The invention discloses a weather resistance stabilizing agent of crack filler and a preparation method. The weather resistance stabilizing agent of the crack filler is prepared from, by mass, 2-3 parts of ethylene-vinyl acetate copolymer, 8-12 parts of vitrified micro bubbles, 1-1.5 parts of acrylic resin, 3-6 parts of hydroxypropyl methyl cellulose, 1-1.3 parts of inorganic aluminum salt water-proofing agents, 0.5-1.5 parts of magnesium aluminium silicate and 1.5-1.9 parts of 107 organic silica gel. Ultrasonic dispersion is conducted on the ethylene-vinyl acetate copolymer and the acrylic resin for 0.5-1 hour, then the inorganic aluminum salt water-proofing agents, the magnesium aluminium silicate and the 107 organic silica gel are added, high-speed stirring and dispersion are conducted for 1-1.5 hours, finally the vitrified micro bubbles and the hydroxypropyl methyl cellulose are added, the mixture is slowly cooled to room temperature, and the weather resistance stabilizing agent of the crack filler is obtained.

Owner:孙军

Slow-release type long-acting super-hydrophobic pollution-flashover-resistant coating material processing technology

InactiveCN108300298AGood fusion effectImprove hydrophobic mobilityAntifouling/underwater paintsPaints with biocidesCarbon blackPower grid

The invention relates to a slow-release type long-acting super-hydrophobic pollution-flashover-resistant coating material processing technology, wherein the ratio among modified polysiloxane, 107 silica gel, hydrophobic gas phase white carbon black, flame retardant, nanometer active metal oxide and other components is reasonable, and the fusion effect is good, such that the slow-release type coating material can easily provide the hydrophobic pollution-flashover-resistant performance. According to the present invention, the process of the novel pollution-flashover-resistant coating material with characteristics of high performance and long service is subjected to targeted development; and various indexes of the coating material are improved by optimizing the parameters of the process, suchthat the finished art product has the high performance and the high use value, the important practical significance can be provided in the anti-fouling work of super high voltage and ultra high voltage power network lines, a lot of construction funds and operation and maintenance costs can be saved, and good social and economic benefits can be created.

Owner:天津市仕翔电气科技有限公司

Gap filler for polished tiles, and preparation method and use method thereof

InactiveCN105254219AEnhance hydrophobicityImprove hydrophobic mobilityAluminum magnesium silicateAcrylic resin

The invention discloses a gap filler for polished tiles. A preparation method of the gap filler comprises the following steps: 1, preparing a base material: crushing quartz sand and limestone to 300-500 meshes, adding glazed hollow beads, hydroxypropyl methyl cellulose, an inorganic aluminum salt waterproof agent and aluminum magnesium silicate, and uniformly stirring; 2, preparing an auxiliary material: mixing an ethylene-vinyl acetate copolymer, acrylic resin, RTV organic silica gel and a pigment, and uniformly stirring; and 3, selecting a pigment according to the color type of the gap filler, adding the base material to a high speed shearing stirrer, sequentially adding the auxiliary material and the selected pigment in a shearing stirring state, stirring at a shearing speed of 6000-8000RPM for 45-90min, and discharging to obtain the gap filler. Gap filling spaces are cleaned, gap filling seams are sprinkled with water until moisture, the gap filler and water are mixed according to a mass ratio of 1:(0.4-0.6) and are blended to form a viscous material, the viscous material is filled between the tiles, water is sprinkled after the viscous material is dried, and then natural drying is carried out.

Owner:孙军

Improved slow-release long-acting super-hydrophobic pollution-flashover-resistant coating material

InactiveCN108300297AReasonable proportionGood for hydrophobic and anti-fouling flashover performanceCoatingsUltra high voltageNano al2o3

The invention relates to an improved slow-release long-acting super-hydrophobic pollution-flashover-resistant coating material. According to the present invention, based on the slow-release long-acting super-hydrophobic pollution-flashover-resistant coating material, nanometer active metal oxides such as nanometer titanium dioxide, nanometer alumina and nanometer zinc oxide are added in an improved manner, and the ratio is optimized, such that the catalytic effect is improved, the improved slow-release long-acting super-hydrophobic pollution-flashover-resistant coating material can be efficiently processed, the RTV is strengthened, and the mechanical property, the electrical property and the anti-aging property of the coating are improved; the surface structure and the characteristics of the RTV coating are improved with the nanometer powder material, such that the self-cleaning ability and the water repellency of the coating are enhanced, the coating has the good effect, and pollutionflashover resistance is easily achieved; and the improved slow-release long-acting super-hydrophobic pollution-flashover-resistant coating material can provide important practical significance in theanti-fouling work of super high voltage and ultra high voltage power network lines, can save a lot of construction funds and operation and maintenance costs, and can create good social and economic benefits.

Owner:天津市仕翔电气科技有限公司

Environment-friendly additive of crack filler and preparation method

The invention discloses an environment-friendly additive of crack filler and a preparation method. The environment-friendly additive of the crack filler is characterized by being prepared from, by mass, 2-3 parts of ethylene-vinyl acetate copolymer, 8-12 parts of vitrified micro bubbles, 2-2.4 parts of gas phase silicon dioxide, 1-1.5 parts of acrylic resin, 3-6 parts of hydroxypropyl methyl cellulose, 1-1.3 parts of inorganic aluminum salt water-proofing agents, 0.5-1.5 parts of ferrous sulfate, 1.5-1.9 parts of RTV organic silica gel and 0.4-0.6 part of antioxygen 1076. Ultrasonic dispersion is conducted on the ethylene-vinyl acetate copolymer and the acrylic resin for 0.5-1 hour, then the gas phase silicon dioxide, the inorganic aluminum salt water-proofing agents, magnesium aluminium silicate, the antioxygen 1076 and the RTV organic silica gel are added, high-speed stirring and dispersion is conducted for 1-1.5 hours, finally the vitrified micro bubbles and the hydroxypropyl methyl cellulose are added, the mixture is slowly cooled to room temperature, and the environment-friendly additive of the crack filler is obtained.

Owner:孙军

Green, environmentally-friendly and discoloration and fading-free gap filler, and preparation method and use method thereof

The invention discloses a green, environmentally-friendly and discoloration and fading-free gap filler. A preparation method of the gap filler comprises the following steps: 1, preparing a base material: crushing quartz sand and an air purifying decoration material named Kasongshi to 300-500 meshes, adding glazed hollow beads, hydroxypropyl methyl cellulose, an inorganic aluminum salt waterproof agent and ferrous sulfate, and uniformly stirring; 2, preparing an auxiliary material: mixing an ethylene-vinyl acetate copolymer, acrylic resin, fumed silica, RTV organic silica gel and an antioxidant 1076, and uniformly stirring; and 3, selecting an iron oxide pigment according to the color type of the gap filler, adding the base material to a high speed shearing stirrer, sequentially adding the auxiliary material and the iron oxide pigment in a shearing stirring state, stirring at a shearing speed of 6000-8000RPM for 45-90min, and discharging to obtain the gap filler. Gap filling spaces are cleaned, gap filling seams are sprinkled with water until moisture, the gap filler and water are mixed according to a mass ratio of 1:(0.4-0.6) and are blended to form a viscous material, the viscous material is filled between tiles, water is sprinkled after the viscous material is dried, and then natural drying is carried out.

Owner:孙军

Processing technology of a slow-release long-lasting super-hydrophobic antifouling flashover coating

ActiveCN106811116BImprove hydrophobic mobilityTo achieve the purpose of slow-release anti-pollution flashoverCoatingsPolymer scienceFumed silica

The invention discloses a processing technology of a slow-release long-acting super hydrophobic anti-pollution flashover coating. The processing technology comprises the following steps: first, preparing hydroxypropyl-terminated fluorinated polysiloxane, hydroxyl-terminated polysiloxane and hydrophobic fumed silica; second, adding the hydroxypropyl-terminated fluorinated polysiloxane and hydroxyl-terminated polysiloxane together with 107 silicone rubber, nano zinc oxide, oil amino oleate, mica powder and aluminum hydroxide into a mixer, stirring uniformly, and grinding for 3-4 times on a three-roller machine to obtain a uniform sizing material; third, adding the uniform sizing material into a kneading machine, adding the hydrophobic fumed silica, heating to 145-150 DEG C, kneading for 1-2 hours and cooling to 20-30 DEG C; and after that, adding a ketoxime crosslinking agent, dimethylamino propylamine, a silane coupling agent and an organic solvent, and stirring uniformly to obtain slow-release long-acting super hydrophobic anti-pollution flashover coating. In the coating prepared by the preparation method disclosed by the invention, the aims of slow release and pollution prevention can be achieved through the combination of the hydroxypropyl-terminated fluorinated polysiloxane and hydroxyl-terminated polysiloxane, and the hydrophobicity transfer of the coating can be remarkably improved.

Owner:STATE GRID CORP OF CHINA +1

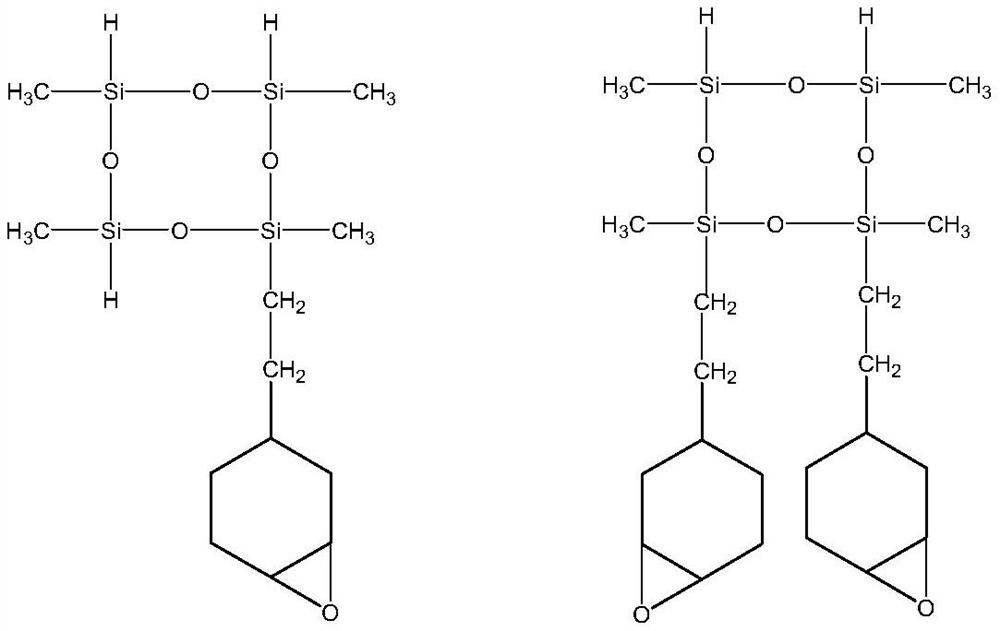

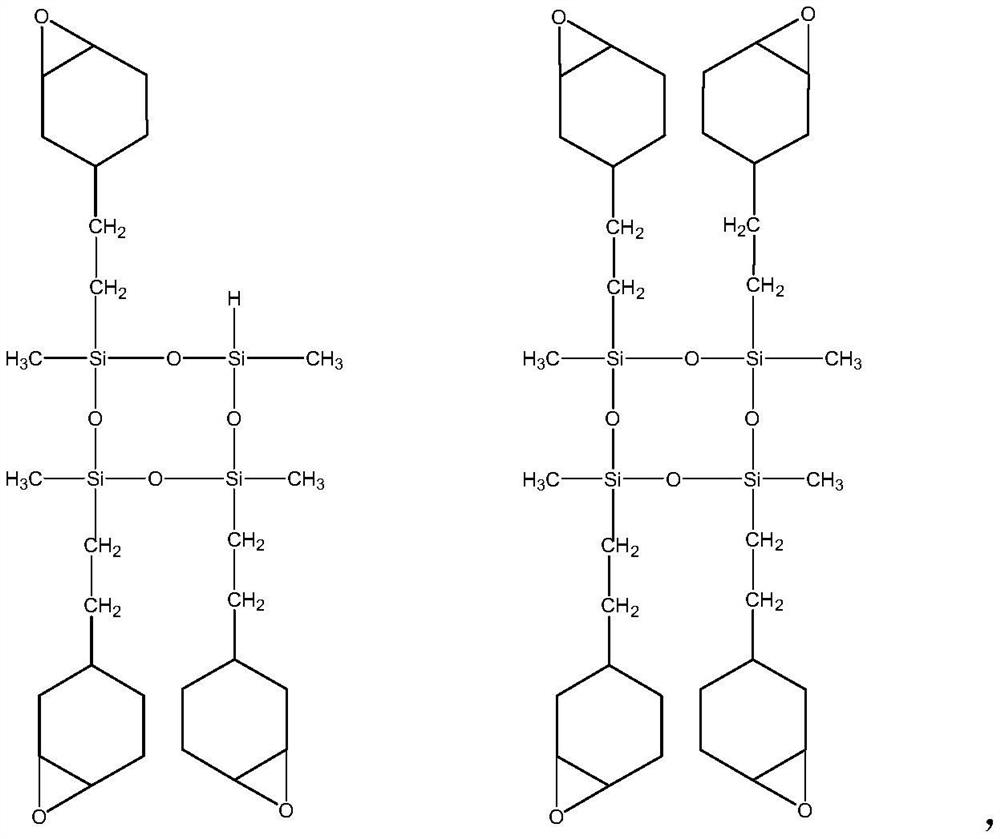

A kind of epoxy resin insulation material and its preparation method and application

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Radioresistant joint mixture accelerant for computer room and preparing method

The invention discloses a radioresistant joint mixture accelerant for a computer room. The radioresistant joint mixture accelerant is characterized by being prepared from, by mass, 2 parts to 3 parts of ethylene-vinyl acetate copolymers, 8 parts to 12 parts of hole-formed expanded perlite, 2 parts to 2.4 parts of organosilicon flatting agents, 1 part to 1.5 parts of acrylic resin, 3 parts to 6 parts of hydroxypropyl methyl cellulose, 1 part to 1.3 parts of inorganic aluminum salt water-proof agents, 0.5 part to 1.5 parts of magnesium aluminum silicate, 1.5 parts to 1.9 parts of RTV organic silica gel and 5 parts to 8 parts of 400-mesh barite powder. A preparing method includes the steps that the ethylene-vinyl acetate copolymer and the acrylic resin are dispersed through ultrasonic waves for 0.5 h to 1 h, then the organosilicon flatting agents, the inorganic aluminum salt water-proof agents, the magnesium aluminum silicate, the 400-mesh barite powder and the RTV organic silica gel are added, the mixture is rapidly stirred and dispersed for 1 h to 1.5 h, finally the hole-formed expanded perlite and the hydroxypropyl methyl cellulose are added, and the temperature of the mixture is slowly reduced to the indoor temperature.

Owner:孙军

An improved slow-release long-lasting super-hydrophobic antifouling flashover coating

ActiveCN106811117BImprove hydrophobic mobilityTo achieve the purpose of slow-release anti-pollution flashoverCoatingsFumed silicaMechanical property

The invention discloses an improved Type-1 slow-release long-acting superhydrophobic anti-pollution-flashover paint which is composed of the following raw materials in parts by weight: 35-45 parts of hydroxypropyl-terminated fluorine-containing polysiloxane, 20-30 parts of hydrogen-terminated polysiloxane, 55-65 parts of 107 silicone rubber, 20-30 parts of hydrophobic fumed silica, 3-5 parts of nano zinc oxide, 2-4 parts of amino oleate, 4-6 parts of nano calcium carbonate, 1-3 parts of ketoxime crosslinking agent, 5-10 parts of talcum powder, 1-2 parts of silane coupling agent, 1-2 parts of decabromodiphenyl oxide and 165-175 parts of organic solvent. The improved Type-1 slow-release long-acting superhydrophobic anti-pollution-flashover paint has the advantages of high mechanical properties, long service life (up to 15 years), favorable flame retardancy (Grade FV-0), favorable salt fog aging resistance and excellent pollution resistance, can still be effective in the smog pollution days, achieves the expected anti-pollution-flashover effect, and avoids the pollution flashover accident.

Owner:STATE GRID CORP OF CHINA +1

A kind of superhydrophobic electric rubber and preparation method thereof

ActiveCN112280313BSolve the problem of insufficient hydrophobicityImprove hydrophobic mobilityPolymer scienceMeth-

The invention belongs to the technical field of rubber, and proposes a super-hydrophobic electric rubber, comprising: 30-50 parts of filler, 0-10 parts of sodium polyacrylate, 60-150 parts of sodium silicate, 10-12 parts by mass. Parts of dimethyldiethoxysilane, 3-4 parts of vinyl silane coupling agent, 1-2 parts of ethyl orthosilicate, 0-3 parts of pigment, 10-15 parts of white carbon black, 35-55 parts of γ ‑Trifluoropropylmethicone, 10‑15 parts hydroterminated polysiloxane, 8‑15 parts α‑vinyl‑α, ω‑dialkoxypolydimethylsiloxane, 3 parts ‑15 parts structuring control agent, 5‑12 parts vulcanizing agent, 150‑180 parts water, 5‑8 parts silica, 3‑6 parts aluminum hydroxide, 4‑6 parts polypropylene fiber, 1‑2 parts 2 , 5‑Dimethyl‑2, 5‑di-tert-butylperoxyhexane. Through the above technical solution, the problem of insufficient hydrophobic migration of rubber in the prior art is solved.

Owner:HEBEI SILICON VALLEY CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com