Silicone rubber for cold-shrinkable power cable accessory and preparation method of silicone rubber

A power cable and silicone rubber technology, which is applied in the field of silicone rubber for cold-shrinkable power cable accessories and its preparation, can solve the problems of large mechanical properties of silicone rubber, poor tensile strength, elongation and tear strength, Add additional risks and other issues to achieve the effect of excellent physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

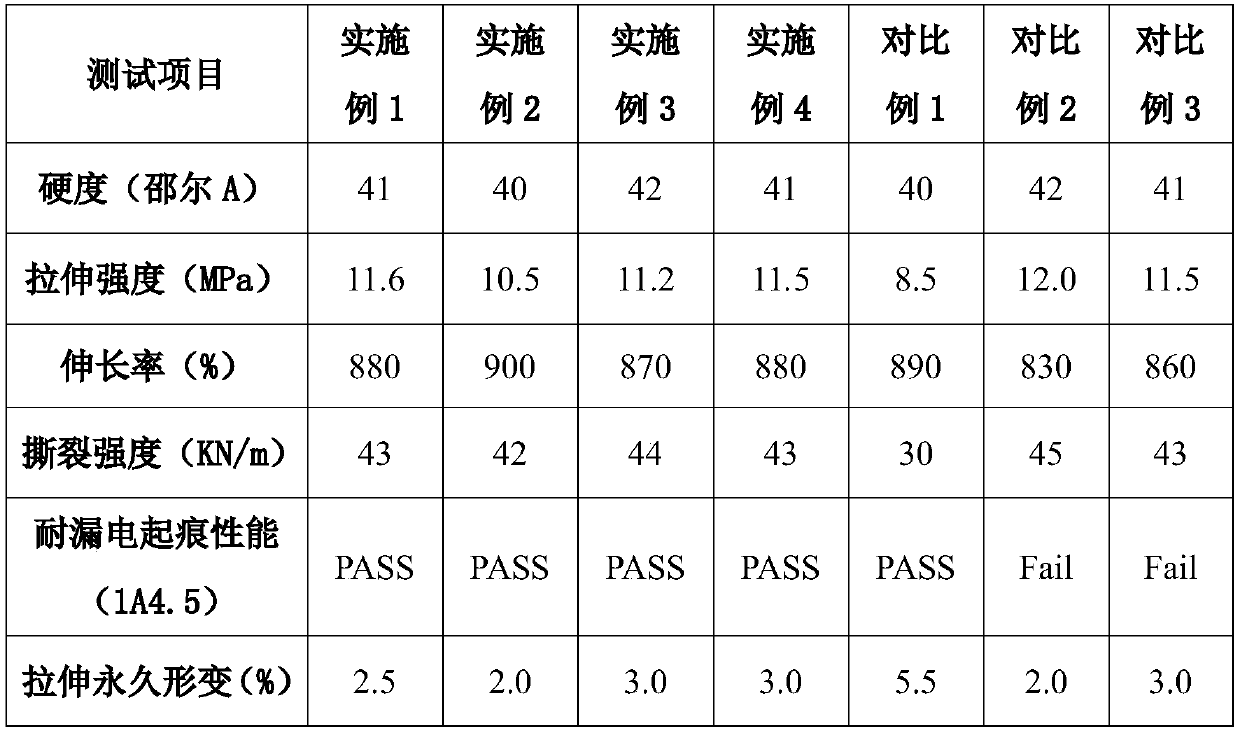

Examples

Embodiment 1

[0088] Each raw material composition is as follows:

[0089] 8 parts of methyl vinyl silicone rubber with a molar mass of 500,000 g / mol and a vinyl content of 3%, 8 parts of methyl vinyl silicone rubber with a molar mass of 650,000 g / mol and a vinyl content of 0.05%. 147 parts of glue, BET method specific area is 200m 2 60 parts of fumed white carbon black per g, 6 parts of hexamethyldisilazane, 3 parts of deionized water, 0.5 part of nano titanium dioxide with a particle diameter of 5 nm, 1 part of nano cerium oxide with a particle diameter of 7 nm, benzene 0.5 parts of phenyl silicone oil with a base molar mass fraction of 41%, 0.3 parts of zinc stearate, 0.2 parts of stearic acid, 0.2 parts of alcohol-modified chloroplatinic acid, 0.2 parts of benzotriazole, 2,5-dimethyl 1 part of 2,5 di-tert-butylperoxyhexane.

[0090] The preparation method of silicone rubber is as follows:

[0091] A. Add all methyl vinyl silicone rubber raw rubber and part of white carbon black in th...

Embodiment 2

[0095] Each raw material composition is as follows:

[0096] 5 parts of methyl vinyl silicone rubber with a molar mass of 450,000 g / mol and a vinyl content of 2%, 5 parts of methyl vinyl silicone rubber with a molar mass of 700,000 g / mol and a vinyl content of 0.16%. 155 parts of glue, the specific area of BET method is 150m 2 50 parts of fumed silica / g, 5 parts of hexamethyldisilazane, 2.5 parts of deionized water, 2 parts of nano titanium dioxide with a particle diameter of 8nm, 2 parts of nano cerium oxide with a particle diameter of 10nm, benzene 1 part of phenyl silicone oil with a base molar mass fraction of 43%, 0.5 part of zinc stearate, 0.3 part of stearic acid, 0.5 part of alcohol-modified chloroplatinic acid, 0.1 part of benzotriazole, 2,5-dimethyl 1.5 parts of base-2,5 di-tert-butylperoxyhexane.

[0097] The preparation method of silicone rubber is the same as that of Example 1.

Embodiment 3

[0099] Each raw material composition is as follows:

[0100] 3 parts of methyl vinyl silicone rubber with a molar mass of 550,000 g / mol and a vinyl content of 4%, 3 parts of methyl vinyl silicone rubber with a molar mass of 600,000 g / mol and a vinyl content of 0.08% 137 parts of glue, BET method specific area is 380m 2 40 parts of fumed silica / g, 4 parts of hexamethyldisilazane, 2 parts of deionized water, 1.5 parts of nano-titanium dioxide with a particle diameter of 10 nm, 0.5 parts of nano-cerium oxide with a particle diameter of 7 nm, benzene 2 parts of phenyl silicone oil with base molar mass fraction of 41%, 0.1 part of zinc stearate, 0.1 part of stearic acid, 0.3 part of alcohol-modified chloroplatinic acid, 0.3 part of benzotriazole, 2,5-dimethyl 0.5 parts of 2,5-di-tert-butylperoxyhexane.

[0101] The preparation method of silicone rubber is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com