Slow-release type long-acting super-hydrophobic pollution flashover prevention coating

An anti-fouling flashover coating and super-hydrophobic technology, applied in the field of coatings, can solve the problems of low elongation, breaking strength and tear strength, easy aging service life, poor corrosion resistance, etc., and achieve salt spray aging resistance Good, excellent stain resistance, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

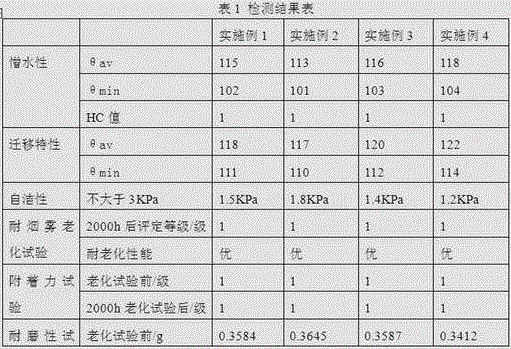

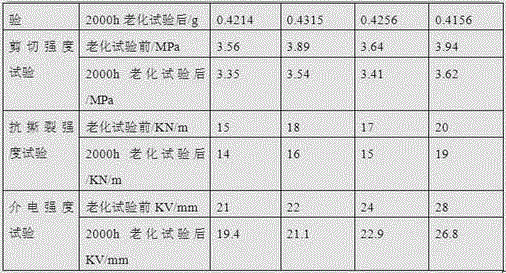

Examples

preparation example Construction

[0048] The preparation method of slow-release type long-acting super-hydrophobic antifouling flashover coating of the present invention, comprises the following steps:

[0049] ① Stir trifluoropropylmethylcyclotrisiloxane, tetramethyldisiloxane and methylcyclosiloxane evenly, add sodium sulfate, stir evenly, heat up to 60~70°C, and then add dropwise Concentrated hydrochloric acid with a concentration of 37%, react for 1-2 hours after the dropwise addition, cool to 20-30°C, add ammonia water, adjust the pH to 6-7, and obtain hydrogen-terminated fluorine-containing polysiloxane; wherein trifluoropropyl The mass ratio of methylcyclotrisiloxane, tetramethyldisiloxane, methylcyclosiloxane, sodium sulfate and concentrated hydrochloric acid is 4~6:1:10~15:0.5~1:0.2~0.5;

[0050] ② Stir the hydrogen-terminated fluorine-containing polysiloxane and methallyl alcohol obtained in step ①, add metal nickel, heat up to 80-90°C, and react for 1-2 hours to obtain hydroxypropyl-terminated fluor...

Embodiment 1

[0057] A slow-release long-acting super-hydrophobic anti-fouling flashover coating, which is composed of the following raw materials: 35kg of hydroxypropyl-terminated fluoropolysiloxane, 20kg of hydrogen-terminated polysiloxane, 55kg of 107 silicone rubber, and hydrophobic gas-phase white 20kg of carbon black, 3kg of nano-zinc oxide, 2kg of oleyl amino oleate, 4kg of mica powder, 1kg of ketoxime type crosslinking agent, 5kg of dimethylaminopropylamine, 1kg of silane coupling agent, 3kg of aluminum hydroxide and 165kg of organic solvent;

[0058] The hydroxypropyl-terminated fluorine-containing polysiloxane is obtained according to the following steps:

[0059] ①Stir 100kg of trifluoropropylmethylcyclotrisiloxane, 25kg of tetramethyldisiloxane and 250kg of methylcyclosiloxane evenly, add 12.5kg of sodium sulfate, heat up to 60°C after stirring evenly, and then add Add 5kg of concentrated hydrochloric acid with a concentration of 37% dropwise, react for 1 hour after the dropwise...

Embodiment 2

[0064] A slow-release long-acting super-hydrophobic anti-fouling flashover coating, which is composed of the following raw materials: 45kg of hydroxypropyl-terminated fluoropolysiloxane, 30kg of hydrogen-terminated polysiloxane, 65kg of 107 silicone rubber, and hydrophobic gas-phase white 30kg of carbon black, 5kg of nano zinc oxide, 4kg of oleyl amino oleate, 6kg of mica powder, 3kg of ketoxime type crosslinking agent, 10kg of dimethylaminopropylamine, 2kg of silane coupling agent, 6kg of aluminum hydroxide and 175kg of organic solvent;

[0065] The hydroxypropyl-terminated fluorine-containing polysiloxane is obtained according to the following steps:

[0066] ①Stir 60kg of trifluoropropylmethylcyclotrisiloxane, 10kg of tetramethyldisiloxane and 150kg of methylcyclosiloxane evenly, add 10kg of sodium sulfate, heat up to 70°C after stirring evenly, and then add Add 5kg of concentrated hydrochloric acid with a concentration of 37% dropwise, react for 2 hours after the dropwise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com