Slow-release type long-acting super-hydrophobic pollution-flashover-resistant coating material processing technology

An antifouling flashover coating and processing technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve problems such as the impact of power supply and threats to the safe and stable operation of power systems, and achieve self-cleaning Sexual improvement, good social and economic benefits, and enhanced coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

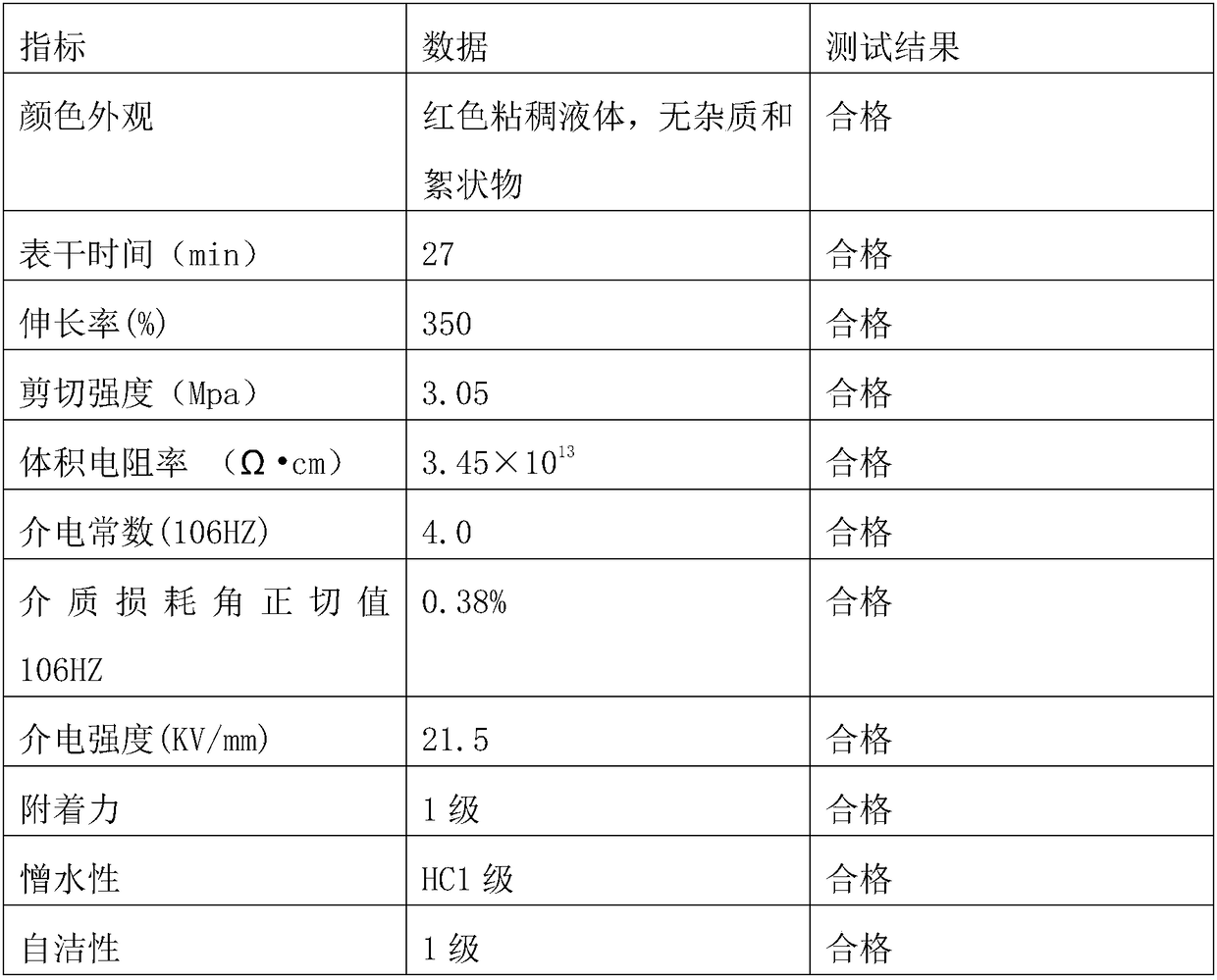

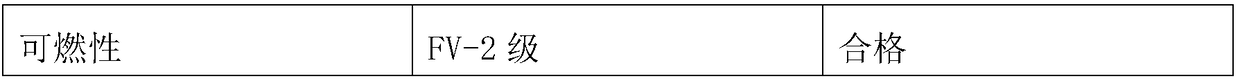

Examples

Embodiment 1

[0026] A slow-release long-acting ultra-hydrophobic anti-fouling flashover paint processing technology, processed according to the following steps:

[0027] (1) 35 parts of modified polysiloxane, 55 parts of 107 silica gel, 35 parts of flame retardant, 1 part of nano-active metal oxide, 3 parts of pigment, and 3 parts of polyaminosiloxane were weighed in proportion, Add to the mixer and stir evenly to form a glue;

[0028] (2) Grind the rubber material mixed in step (1) on a three-roller machine for 3 to 4 times until the rubber material has no particles and the rubber material has a smooth and delicate appearance;

[0029] (3) Add the rubber material ground in step (2) into the planetary machine, set the temperature at 110°C, vacuumize not less than 0.09mpa, and complete the vacuum stirring for 4 hours to remove low boiling matter;

[0030] (4) Press the low boiler removal rubber material in step (3) into the kneader, and add 20 parts of hydrophobic fumed silica in stages, s...

Embodiment 2

[0037] A slow-release long-acting ultra-hydrophobic anti-fouling flashover paint processing technology, processed according to the following steps:

[0038] (1) 40 parts of modified polysiloxane, 60 parts of 107 silica gel, 40 parts of flame retardant, 3 parts of nano-active metal oxide, 5 parts of pigment, and 5 parts of polyaminosiloxane were weighed in proportion, Add to the mixer and stir evenly to form a glue;

[0039] (2) Grind the rubber material mixed in step (1) on a three-roller machine for 3 to 4 times until the rubber material has no particles and the rubber material has a smooth and delicate appearance;

[0040] (3) Add the rubber material ground in step (2) into the planetary machine, set the temperature at 120°C, and the degree of vacuuming should not be lower than 0.09mpa, and then finish after 5 hours of vacuuming and stirring to remove low boilers;

[0041] (4) Press the low boiler removal rubber material in step (3) into the kneader, and add 25 parts of hyd...

Embodiment 3

[0048] A slow-release long-acting ultra-hydrophobic anti-fouling flashover paint processing technology, processed according to the following steps:

[0049](1) 45 parts of modified polysiloxane, 65 parts of 107 silica gel, 45 parts of flame retardant, 5 parts of nano-active metal oxide, 7 parts of pigment, and 7 parts of polyaminosiloxane were weighed in proportion, Add to the mixer and stir evenly to form a glue;

[0050] (2) Grind the rubber material mixed in step (1) on a three-roller machine for 3 to 4 times until the rubber material has no particles and the rubber material has a smooth and delicate appearance;

[0051] (3) Add the rubber material ground in step (2) into the planetary machine, set the temperature at 130°C, and the degree of vacuuming is not lower than 0.09mpa. Vacuumize and stir to remove low boilers for 6 hours before finishing;

[0052] (4) Press the low boiler removal rubber material in step (3) into the kneader, and add 30 parts of hydrophobic fumed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com